Plasma flue gas desulfurization, denitrification and dust removal integrated device

A desulfurization, denitrification, and plasma technology, applied in gas treatment, separation methods, transportation and packaging, etc., can solve the problems of interrupting the flue gas treatment process, time-consuming and labor-intensive flushing of the dust collector, clogging of the dust collector, etc., so as to ensure the clamping efficiency. , Increase the effect of filtering and dust removal, and increase the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

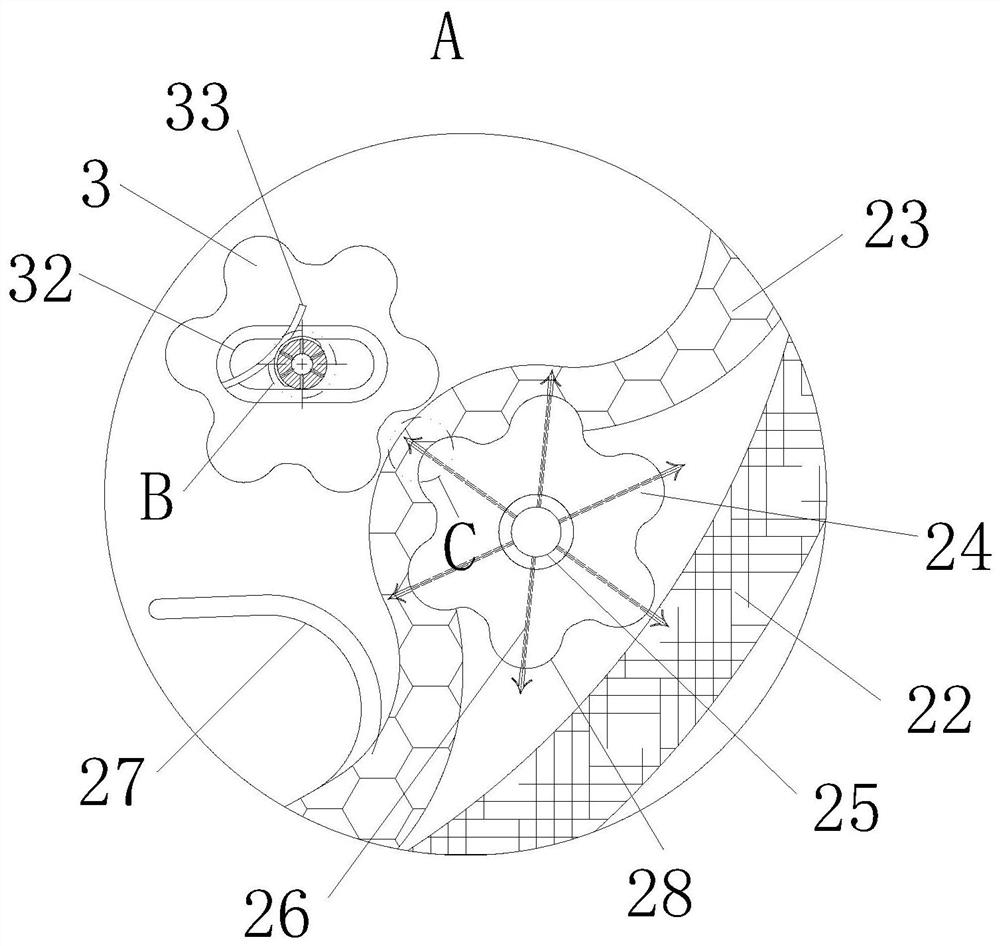

[0032] As an embodiment of the present invention, a group of arc-shaped teeth 28 are evenly distributed on the outer periphery of the driving roller 24, and a driven roller 3 is arranged on the inner periphery of the filter cloth 23 corresponding to the driving roller 24, and the driven roller 3 The outer periphery is provided with an arc-shaped groove matching with the teeth 28; the middle part of the driven roller 3 is fixedly connected with the second rotating shaft 31, and the position corresponding to the second rotating shaft 31 is provided with a chute 32 on the box body 1, and the second rotating shaft 31 It runs through the chute 32 and is slidably connected with the chute 32; the side of the chute 32 away from the driving roller 24 is fixedly connected with an arc-shaped elastic piece 33, and the middle part of the elastic piece 33 resists and presses the second rotating shaft 31; through the teeth 28 Cooperate with the arc-shaped groove of the driven roller 3, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com