Composite electrospun membrane for promoting tendon-bone healing as well as preparation method and application of composite electrospun membrane

An electrospun film and electrospinning technology, which is applied in the field of biomedical materials, can solve the problems of lack of fusion of grafts and bone tunnels, and achieve the effect of improving tendon-bone healing, being highly targeted, and promoting tendon-bone healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 The present invention has a degradable polymer composite electrospun membrane with uniform ceramic content

[0056] (1) Weigh an appropriate amount of polylactic acid (PLA) and add hexafluoroisopropanol solution, and then uniformly stir at 37°C for 1 hour to form a uniform solution with a concentration of 18%;

[0057] (2) Add hydroxyapatite powder with a particle size of 100 nm to the above polymer solution in an amount such that the mass fraction of hydroxyapatite in the finally obtained electrospun membrane is 10%, and stir at 37° C. for 1 h.

[0058] (3) Put the hydroxyapatite / PLA spinning solution obtained in step (2) into the propulsion pump of the spinning machine, the drum speed is 500r / min, the syringe pump propulsion speed is 2.4ml / h, the temperature is 25°C, and the humidity is 65°C. %, the receiving distance is 15cm, and the spinning starts under the condition of voltage 12KV. After the spinning is completed, the primary product of electrospun mem...

Embodiment 2

[0060] Example 2 The present invention has a degradable polymer composite electrospun membrane with uniform ceramic content

[0061] (1) Weigh an appropriate amount of polylactic acid (PLA) and add hexafluoroisopropanol solution, and then uniformly stir at 37°C for 1 hour to form a uniform solution with a concentration of 22%;

[0062] (2) Add hydroxyapatite powder with a particle size of 100 nm to the above polymer solution in an amount such that the mass fraction of hydroxyapatite in the finally obtained electrospun membrane is 45%, and stir at 37° C. for 1 h.

[0063] (3) Put the hydroxyapatite / PLA spinning solution obtained in step (2) into the propulsion pump of the spinning machine, the drum speed is 600r / min, the syringe pump propulsion speed is 3mL / h, the temperature is 25°C, and the humidity is 60%. , the receiving distance is 13cm, and the spinning is started under the condition of voltage 14KV. After the spinning is completed, the primary product of electrospun mem...

Embodiment 3

[0065] Embodiment 3 The present invention has degradable polymer electrospun membrane

[0066] (1) Weigh an appropriate amount of PLCL and add hexafluoroisopropanol solution, and then uniformly stir for 1 hour at 37°C to form a uniform solution with a concentration of 26%;

[0067] (2) Put the PLCL spinning solution obtained in step (1) into the propulsion pump of the spinning machine, the drum speed is 500r / min, the syringe pump propulsion speed is 2.4mL / h, the temperature is 25°C, the humidity is 65%, and the receiving distance is 15cm , Spinning starts under the condition of a voltage of 12KV. After the spinning is completed, the primary electrospun membrane with a certain width is received on the drum tinfoil.

[0068] (3) Dry the primary electrospun membrane obtained in step (2) in a vacuum oven at 37°C for 24 hours to obtain a PLCL electrospun membrane.

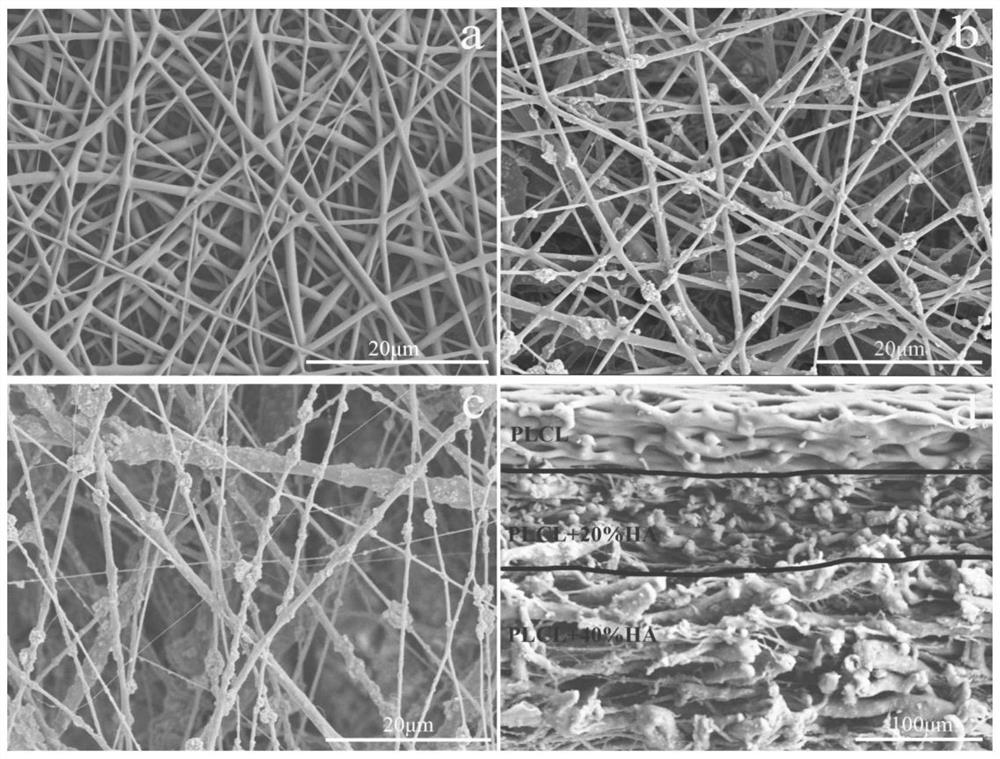

[0069] (4) The SEM image of the PLCL electrospun membrane obtained in step (3) figure 1 (a) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com