Efficient heat dissipation type power distribution cabinet

A heat-dissipating type and power distribution cabinet technology, which is applied in substation/power distribution device casing, electrical components, substation/switch layout details, etc., can solve problems affecting operation efficiency, component damage, and affecting service life, etc., to increase Installation and maintenance efficiency, lower temperature, and faster heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

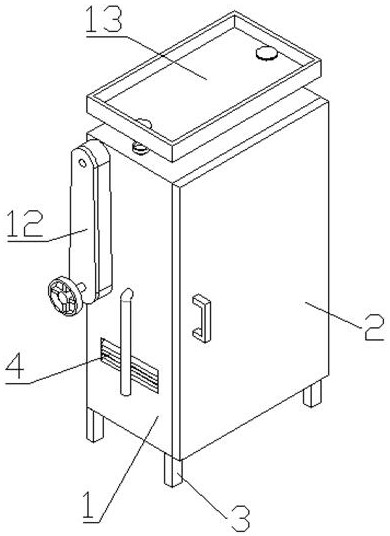

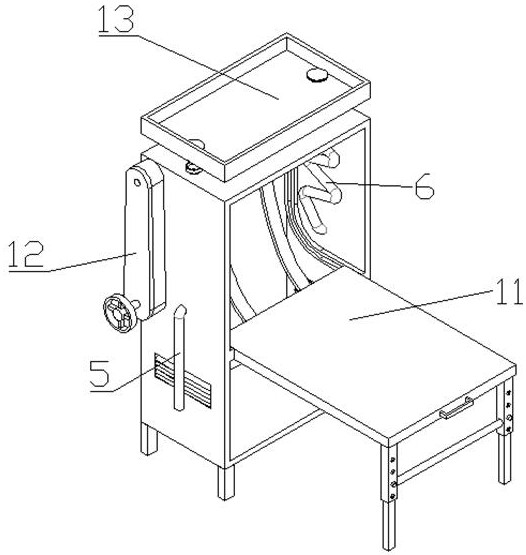

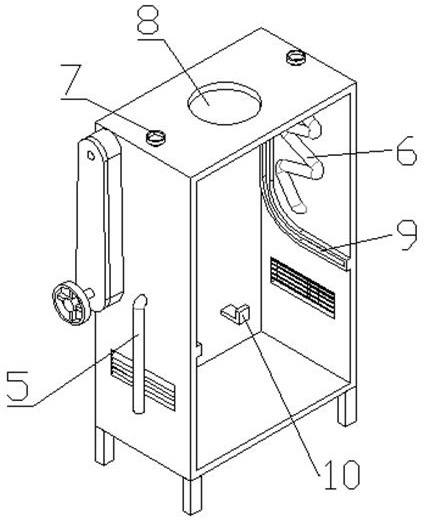

[0020] Such as Figure 1-7 As shown, a high-efficiency heat dissipation power distribution cabinet includes a cabinet body 1, a cabinet door 2, support legs 3, an air inlet 4, a drain pipe 5, a curved pipe 6, a funnel 7, an air outlet 8, a right-angle chute 9, The liner support base 10, the liner device 11, the linkage device 12, and the heat dissipation device 13 are characterized in that: the front side of the cabinet body 1 is hinged with a cabinet door 2, and the bottom of the cabinet body 1 is welded with four supporting legs 3. The lower parts of the left and right sides of the cabinet body 1 are respectively provided with air intake holes 4, the lower water pipes 5 are fixed below the left and right sides of the cabinet body 1, and the upper part of the lower water pipes 5 is connected with a curved pipe 6, and the curved pipe 6 Locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com