Heat coupling methanol reforming hydrogen production fuel cell system

A fuel cell system, reforming hydrogen production technology, applied in fuel cells, fuel cell additives, fuel cell control, etc., can solve problems such as stack heat dissipation, reduce maintenance time, reduce replacement costs, and improve system efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

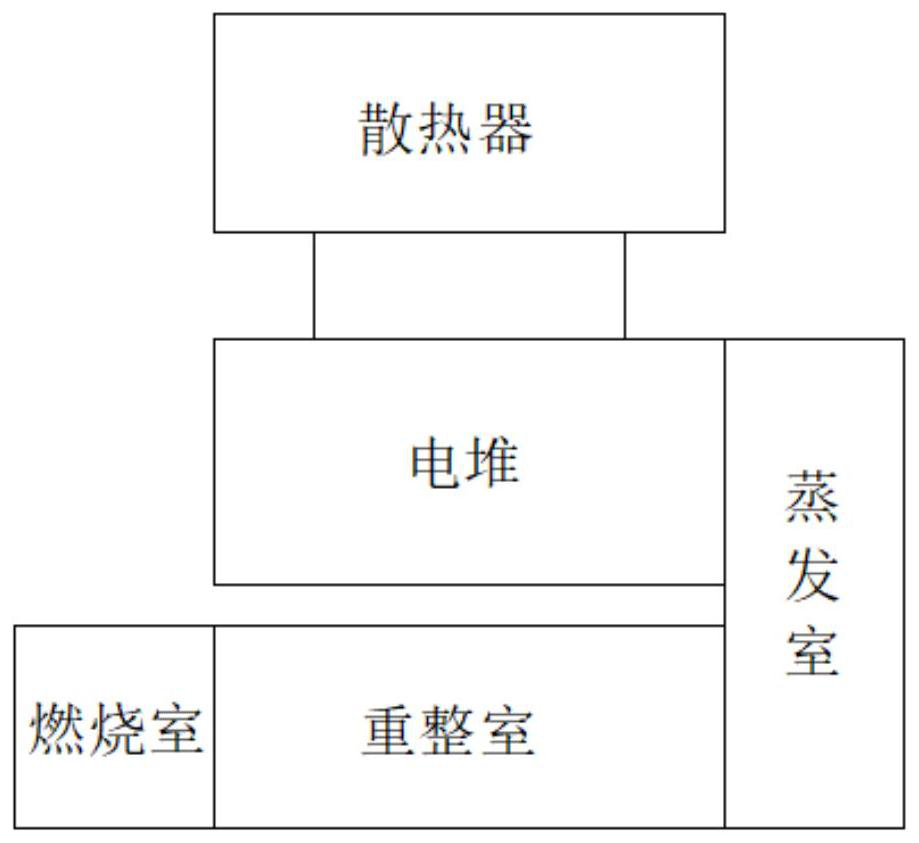

[0018] Taking a 1kW fuel cell system as an example, a normal system needs to be equipped with a radiator, and the heat dissipation is about 400-700W. In this scheme, the system does not need to be equipped with a radiator, and the discharge heat of the stack can be fully utilized, and only part of the hot exhaust gas is discharged from the channel 7, which greatly improves the system efficiency.

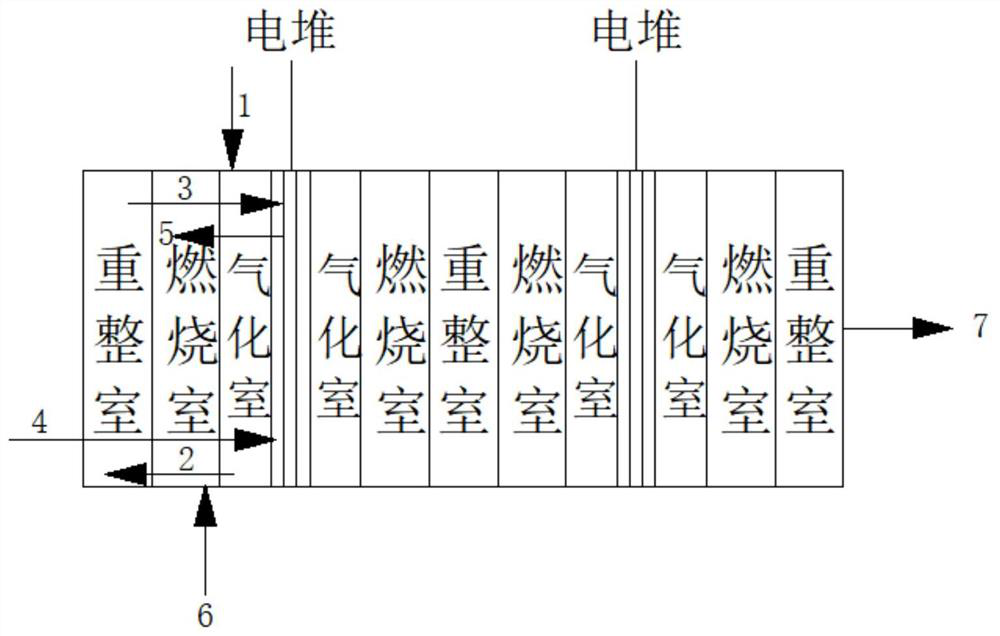

[0019] A heat-coupled methanol reforming hydrogen production fuel cell system consists of the following parts:

[0020] Reforming chamber: methanol reforming hydrogen production reaction occurs, reforming methanol raw material into H 2 and CO 2 . Its working temperature is about 200 ~ 300 ℃.

[0021] Combustion chamber: Oxidation reaction occurs to release heat, methanol, anode tail gas or other raw materials are mixed with oxidant (air, oxygen, etc.), and catalytic combustion is carried out on the surface of the combustion catalyst to provide heat for the reforming chamber and ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com