Insulator structure for power transmission and transformation project and installation method

An installation method and insulator technology, applied in the direction of suspension/strain insulators, insulators, support insulators, etc., can solve problems such as uneven distribution of insulating media, large space occupied by insulators, damage to line use and operating life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

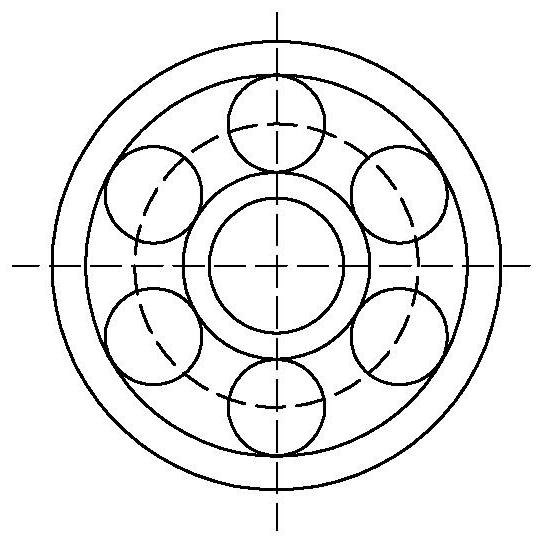

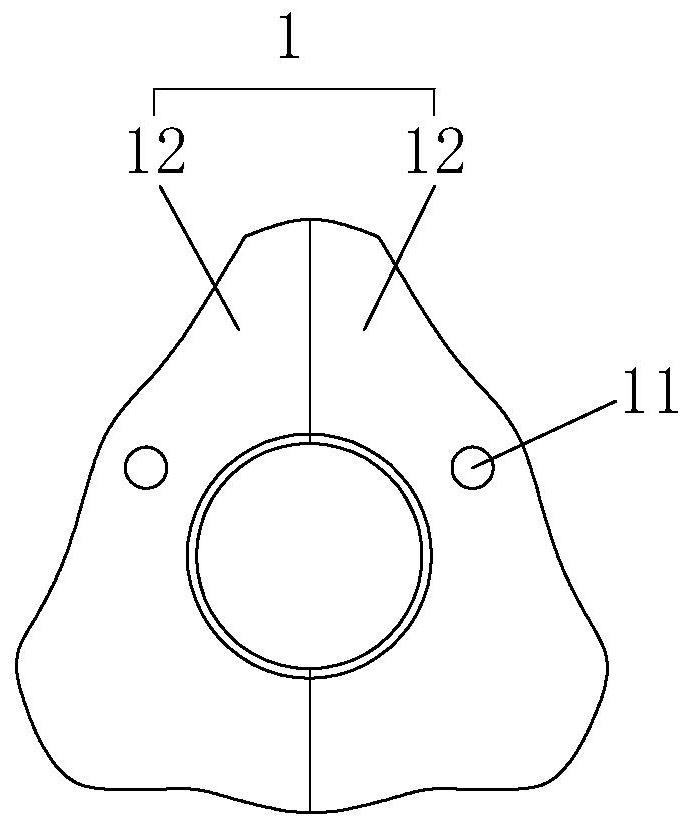

[0027] refer to figure 2 , is an insulator structure for power transmission and transformation projects disclosed by the present invention, including an insulator body 1 with a triangular end face, a press sleeve 2, a connector inner conductor 3 and a connector outer conductor 4, and two air hole 11.

[0028] Wherein, the insulator body 1 includes two insulating parts 12 that are spliced together, and two air holes 11 are respectively arranged on the insulating parts 12. 11 is arranged symmetrically with the center line of the insulator body 1 .

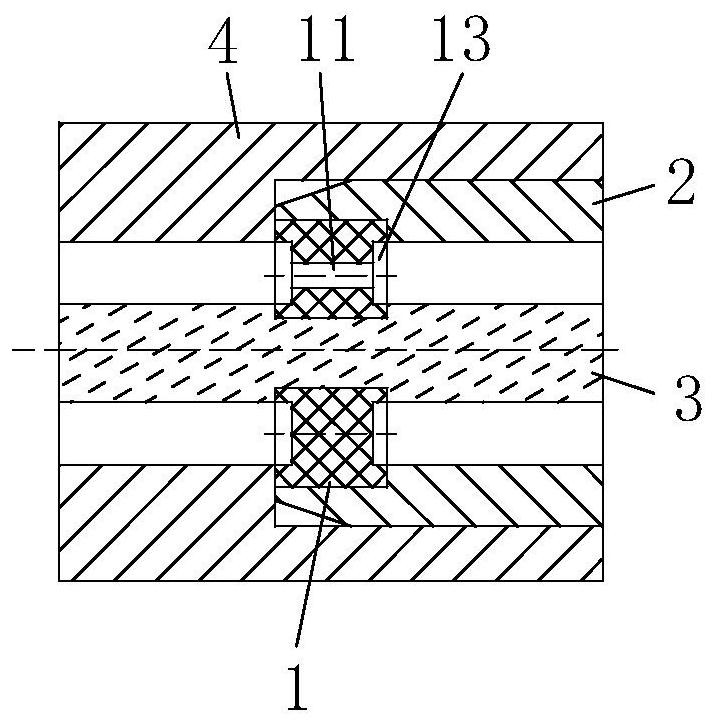

[0029] refer to image 3 , the insulator body 1 is clamped and fixed on the connector inner conductor 3, the insulator body 1 and the connector inner conductor 3 are detachably fixed in the press sleeve 2, the press sleeve 2 is detachably fixed in the connector outer conductor 4, and the connector inside Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com