Air fuel multi-layer three-dimensional grading low-nitrogen gas burner

A gas burner and gas fuel technology, applied in the direction of gas fuel burners, burners, combustion types, etc., can solve problems such as poor effects, and achieve the effects of reducing emissions, improving combustion efficiency, and reducing the degree of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

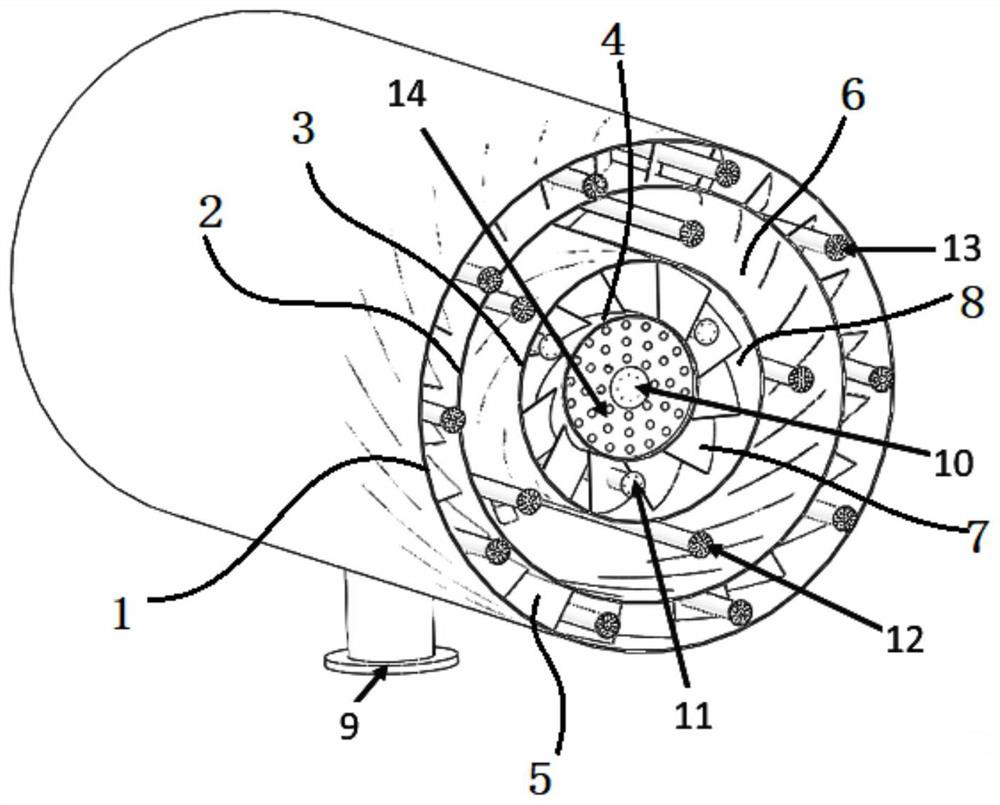

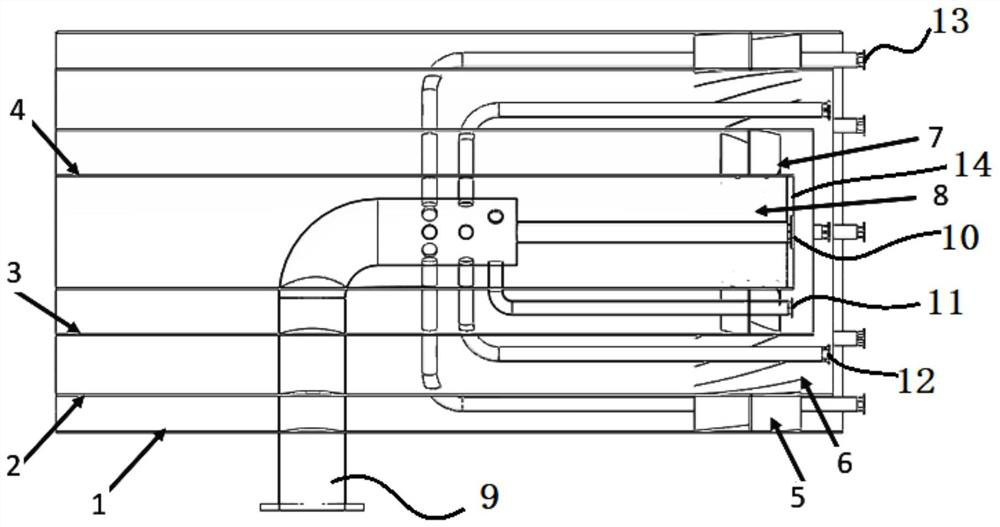

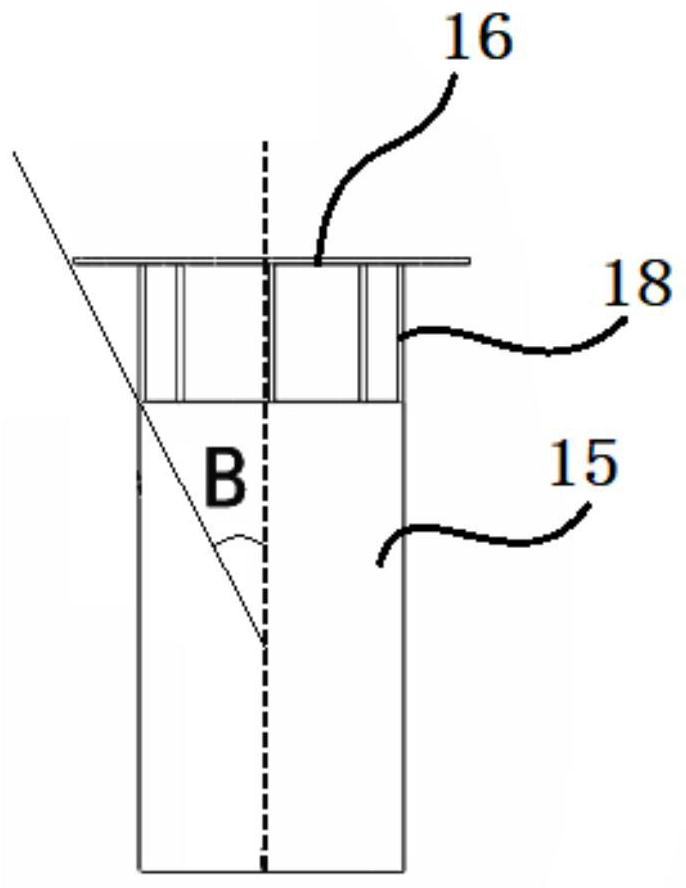

[0042] Such as figure 1 , figure 2 , Fig. 3 (a), Fig. 3 (b), Fig. 4 (a) and Fig. 4 (b) shown, the air-fuel multi-layer three-dimensional graded low-nitrogen gas burner of the present embodiment includes sequential distribution from inside to outside The central fuel gun 10, the central air cylinder 4, the inner primary fuel gun 11, the inner swirling wind outer cylinder 3, the outer primary fuel gun 12, the outer DC air outer cylinder 2, the secondary fuel gun 13 and the outer secondary air outer cylinder 1 . Wherein, a central wind channel 8 is formed between the central fuel gun 10 and the central air cylinder 4, and an annular inner swirling wind area is formed between the central air cylinder 4 and the inner swirling wind outer cylinder 3, and the inner swirling wind outer cylinder 3 and the outer direct current wind An annular direct air area 6 is formed between the outer cylinders 2, and the outer direct air outer cylinder 2 and the outer secondary air outer cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com