Downhole decoupling clutch rotary steering drilling method and reverse motor clutch

A clutch and rotation direction technology, which is applied in directional drilling, drilling equipment and methods, driving devices for drilling in wellbore, etc. Resource utilization efficiency and other issues, to achieve the effect of improving transmission capacity, improving drilling efficiency, and enhancing stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

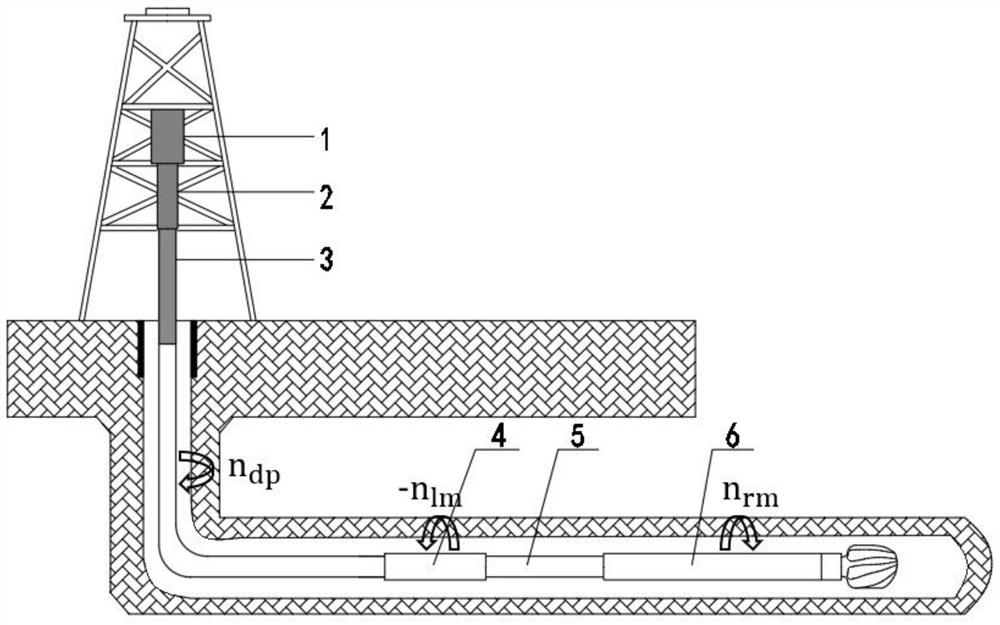

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a downhole decoupling and clutching rotary steerable drilling device.

[0027] The device includes: uphole driving control section, upper drill string, reverse motor clutch and drill bit.

[0028] The reverse motor clutch is connected with the uphole driving control part of the drilling device through the upper drill string, and is connected with the drill bit of the drilling device.

[0029] The reverse motor clutch includes a reverse motor, a lower drill string and a forward motor;

[0030] The stator of the reversing motor 4 and its motor casing are all fixedly connected to the end of the upper drill string away from the uphole d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com