Aluminum anode carbon bowl cleaning cutter and cleaning method

A carbon bowl and anode technology, which is applied in the field of cleaning tools for aluminum anode carbon bowls, can solve the problems of operator's personal health and safety hazards, dust and high-temperature particle splashing, and high labor intensity, so as to avoid unorganized emissions and meet the Clean up the effect, solve the effect of waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described now in conjunction with accompanying drawing.

[0049] The invention provides a cleaning cutter for an anode carbon bowl for aluminum, which is an efficient, quick, safe and environment-friendly cleaning cutter adaptive to the inner surface of the carbon bowl.

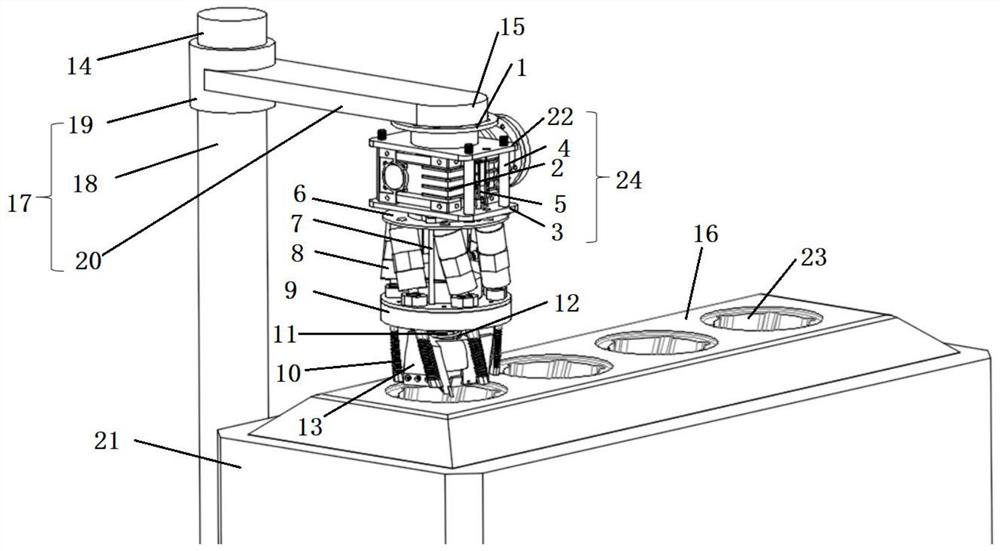

[0050] Such as figure 1 As shown, the cutter includes: a bracket 17, a flange connecting plate 1, a cylinder assembly 24, a longitudinal driving device 14, a bidirectional driving device 15 and a cleaning device;

[0051] The bracket 17 includes: a cylindrical rod 18, a shaft sleeve 19 and an extension arm 20;

[0052] The cylindrical rod 18 is fixed on one side of the carbon electrode platform 21, the shaft sleeve 19 is sleeved on the cylindrical rod 18, and an extension arm 20 is extended in the radial direction of the shaft sleeve 19, and the two are consolidated together; the cylindrical rod 18 A longitudinal driving device 14 is provided at the top, which ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com