Exhaust fan

An exhaust fan and casing technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of the dead angle of the air inlet grille, the high installation of the exhaust fan, and difficulty in cleaning, so as to prevent secondary pollution and save money. The effect of cleaning time and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

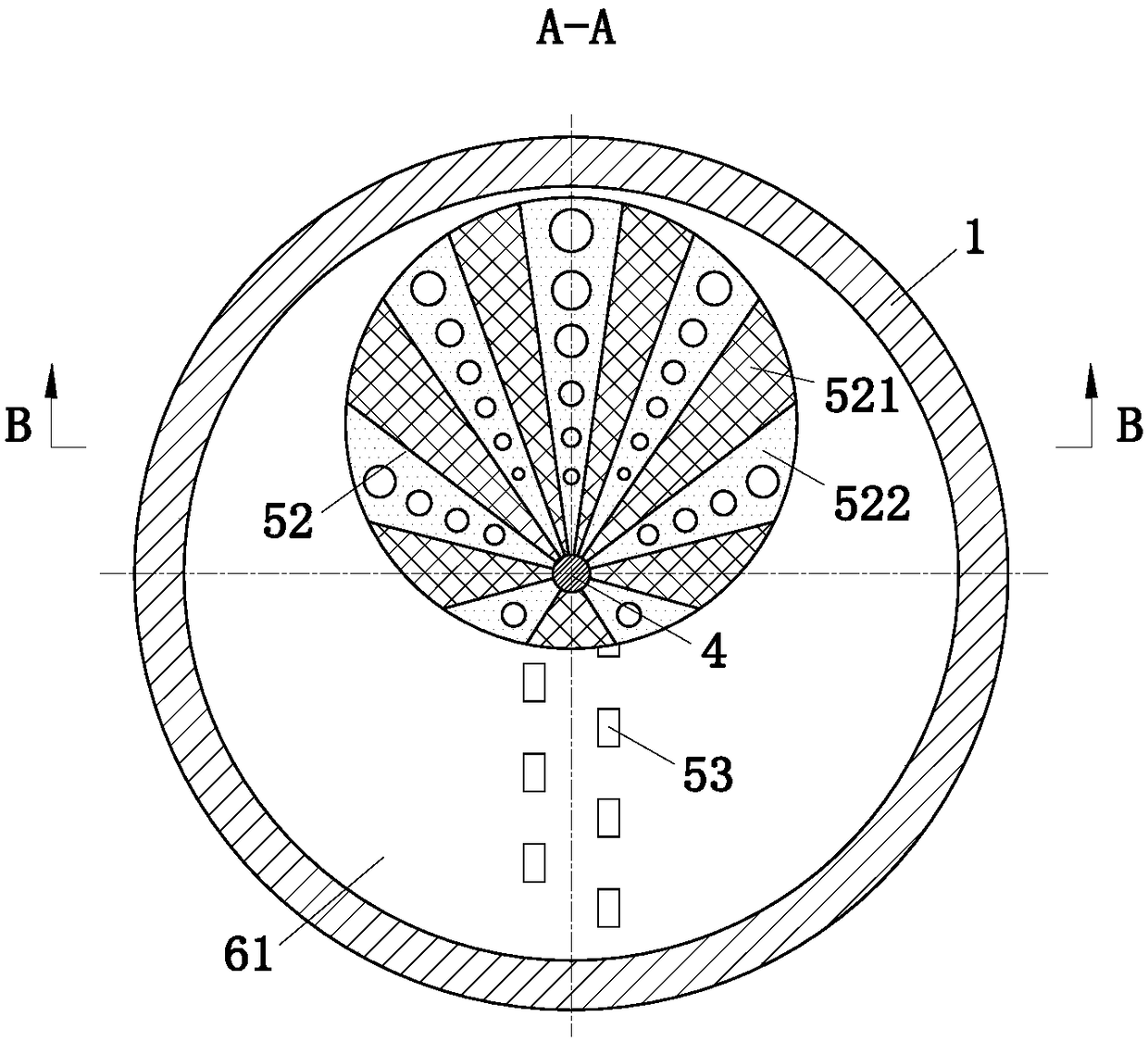

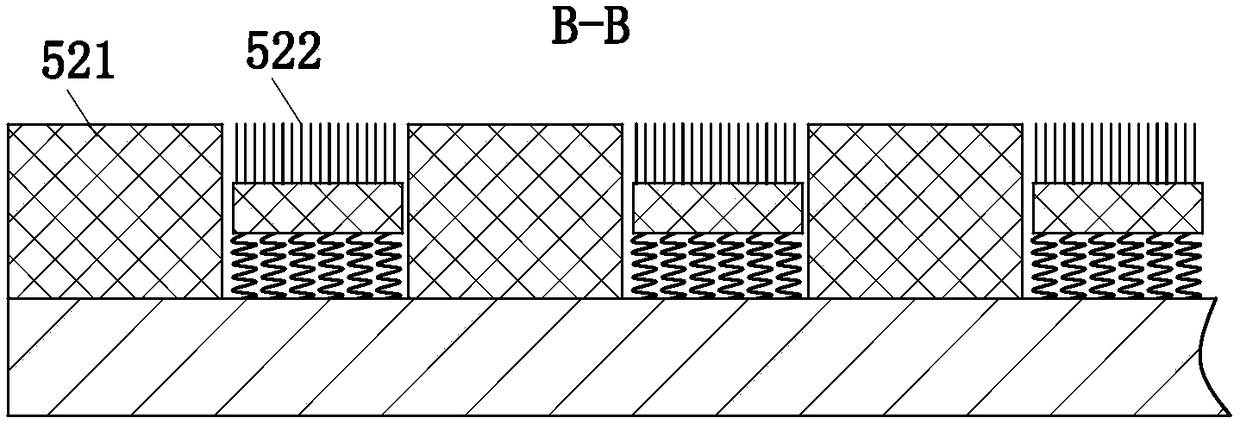

[0028] As an embodiment of the present invention, the dust removal device 5 includes a brush board 51, a wiper board 52, and a water squeeze block 53. The outside of the wind screen cover 61; the wiper 52 is arranged on the inside of the air intake screen 61, and the wiper 52 is used to clean the inside of the air intake screen 61; the water squeezing block 53 is arranged on the inside of the air intake screen 61 , the water squeeze block 53 is used to cooperate with the sponge block 521 on the wiper blade 52 to realize the removal of sewage on the sponge block 521; the brush plate 51 is fixedly connected with the wiper blade 52 through the connecting shaft 4; the wiper blade The plate 52 is disc-shaped, and the wiper blade 52 is mounted eccentrically on the connecting shaft 4; the surface of the wiper blade 52 near the side of the air intake net cover 61 is fixedly mounted with interval radial sponge blocks 521, adjacent to each other. There are brush plates 522 between the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com