Bottle multicolor printing device and using method thereof

A technology of multi-color printing and bottle body, which is applied to printing devices, general parts of printing machinery, printing, etc., can solve the problems of lower printing quality, failure to check the feeding mechanism, and inconsistent intervals between multiple printings, so as to reduce the printing cost. The effect of improving quality and printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

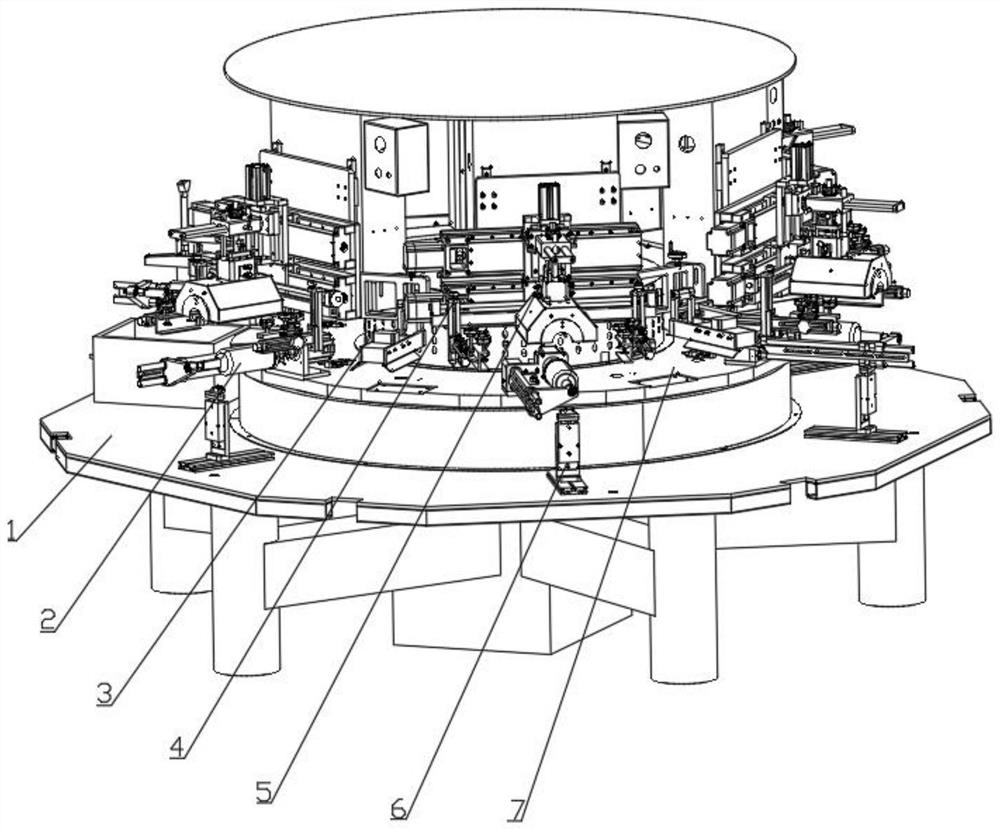

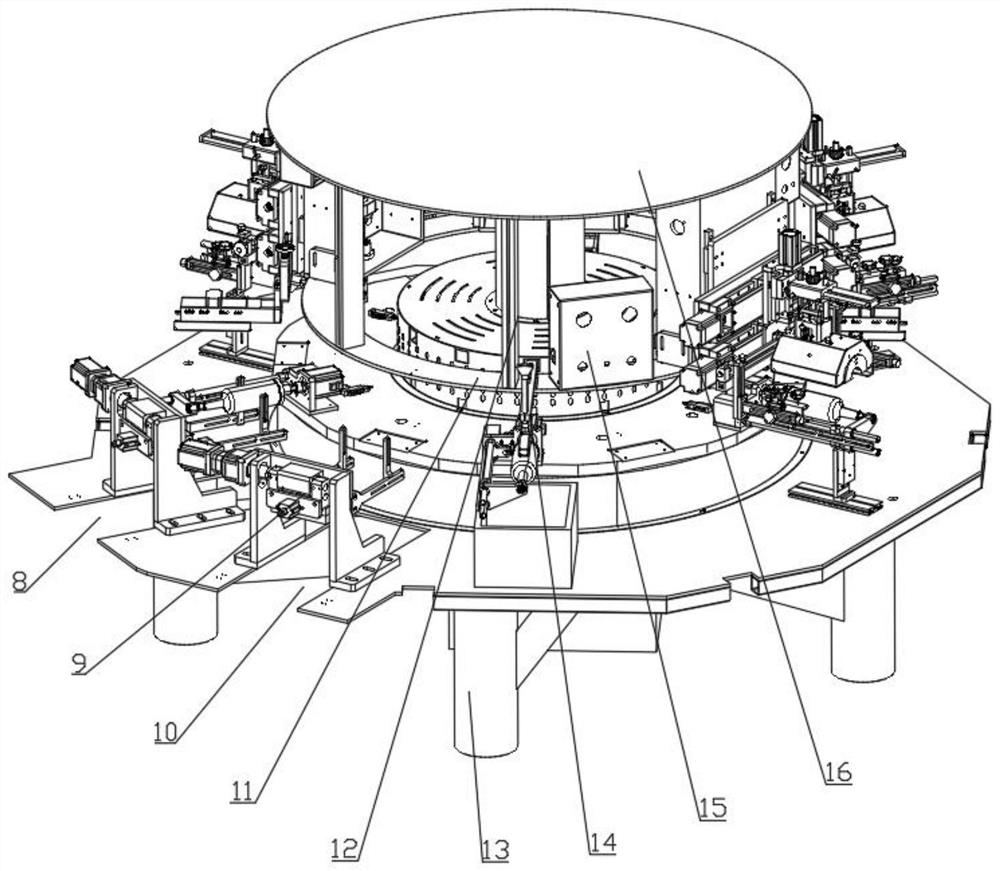

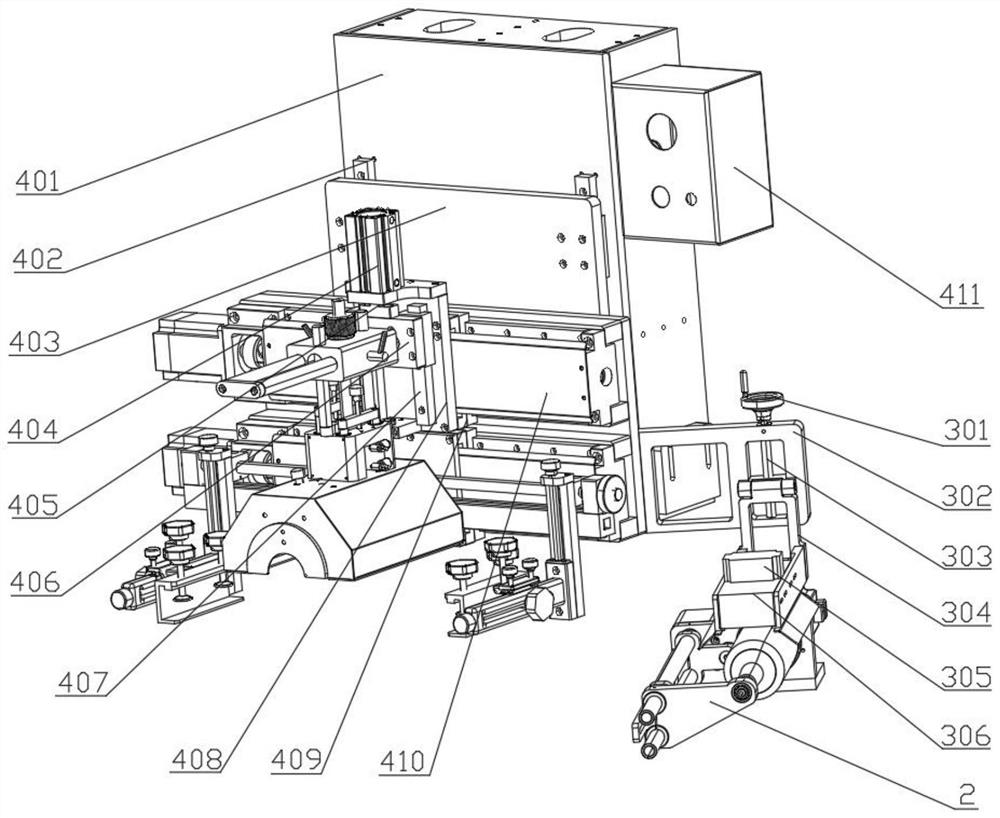

[0065] Such as Figure 1-10 As shown, a bottle body multi-color printing device includes a support frame 13, a feeding mechanism 9, a feeding mechanism 2, a rotating mechanism 7, a printing mechanism, a dust removal mechanism 14, a drying mechanism 3, an installation ring plate 11 and a distribution box 15;

[0066] The outer side of the upper end of the support frame 13 is provided with a placement plate 1, and one end of the placement plate 1 is provided with a feeding port 10 and a feeding port 8 distributed at intervals, and the upper ends of the feeding port 10 and the feeding port 8 are provided with a retrieving mechanism 9, a rotating mechanism 7 is arranged in the middle of the upper end of the support frame 13. There are multiple feeding mechanisms 2, and the multiple feeding mechanisms 2 are annularly distributed outside the upper end of the rotating mechanism 7. The top of the rotating mechanism 7 is provided with a connecting circular plate 16, and the mounting ri...

Embodiment 2

[0076] Such as Figure 1-10 As shown, a bottle body multi-color printing device includes a support frame 13, a feeding mechanism 9, a feeding mechanism 2, a rotating mechanism 7, a printing mechanism, a dust removal mechanism 14, a drying mechanism 3, an installation ring plate 11 and a distribution box 15;

[0077] The outer side of the upper end of the support frame 13 is provided with a placement plate 1, and one end of the placement plate 1 is provided with a feeding port 10 and a feeding port 8 distributed at intervals, and the upper ends of the feeding port 10 and the feeding port 8 are provided with a retrieving mechanism 9, a rotating mechanism 7 is arranged in the middle of the upper end of the support frame 13. There are multiple feeding mechanisms 2, and the multiple feeding mechanisms 2 are annularly distributed outside the upper end of the rotating mechanism 7. The top of the rotating mechanism 7 is provided with a connecting circular plate 16, and the mounting ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com