3D printing control system for dual laser segmentation and its segmentation method

A 3D printing and control system technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve problems such as difficult to achieve printing balance on both sides, reduce printing efficiency, waste of resources, etc., to make up for the inconsistent length of printing time gap, improved balance, effect of improved balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present application will be further illustrated in conjunction with the accompanying drawings and examples.

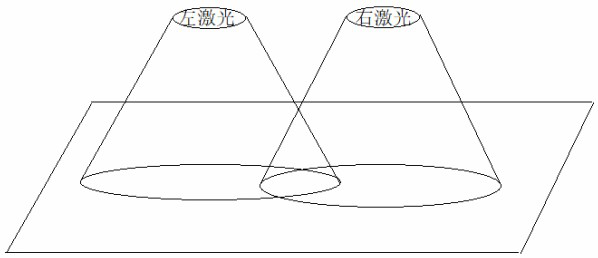

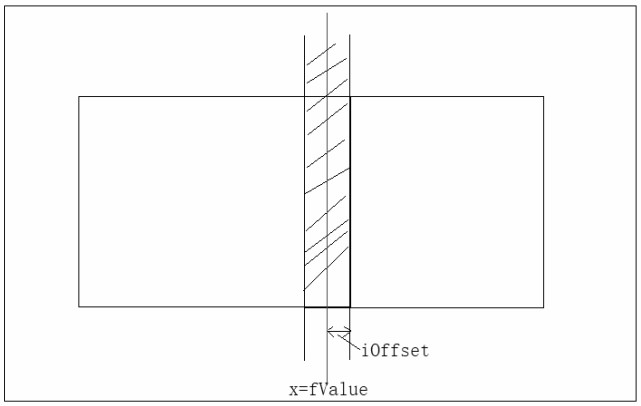

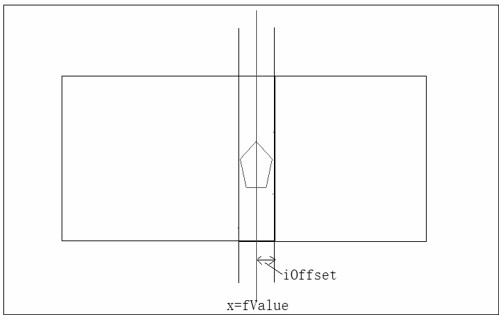

[0067] Such as Figure 1 - Figure 13 As shown, a 3D print control system divided for dual laser, including:

[0068] Two lasers are provided with two lasers on the left and right sides of the 3D printing cabin, and the laser on the left is the left laser. The laser in the right is the right laser. The laser emitted by the left laser is the left laser, the right laser, the laser, the right laser, the right laser, Left laser and right lasers constitute double lasers;

[0069] The left laser and the right laser are respectively connected to the left laser spray mirror and the right laser spray mirror, and the left laser spray mirror and the right laser spray mirror are connected to the left vibrating mirror card and the right vibrating mirror board, the left. The mirror card and the right vibration gauge are connected to the upper machine communication; the host com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com