Post-treatment method for printed intermediate of stereo lithography appearance 3D printed piece

A 3D printing and intermediate technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of incomplete curing of photosensitive resin materials, high speed, and low structural strength of printing intermediates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described in detail below in conjunction with specific embodiments.

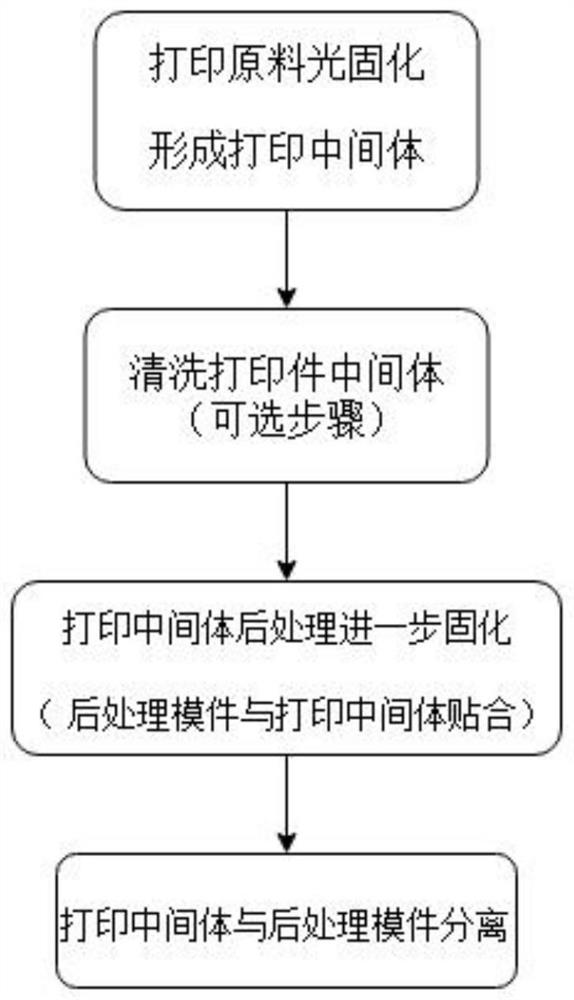

[0030] Such as figure 1 As shown, the photo-curing 3D printing post-processing method of the present invention mainly includes the following steps: 1. Photo-curing and printing the printing material through a photo-curing printing device to form a printing intermediate (not completely cured); 2. Optionally printing The intermediate is cleaned; 3. After the printing intermediate is bonded with the post-processing module, the post-processing is carried out together, so that the printing intermediate is further cured; 4. The printing intermediate is further cured to form a print with mechanical properties that meet the requirements, and then the printed The parts can be separated from the post-processing module.

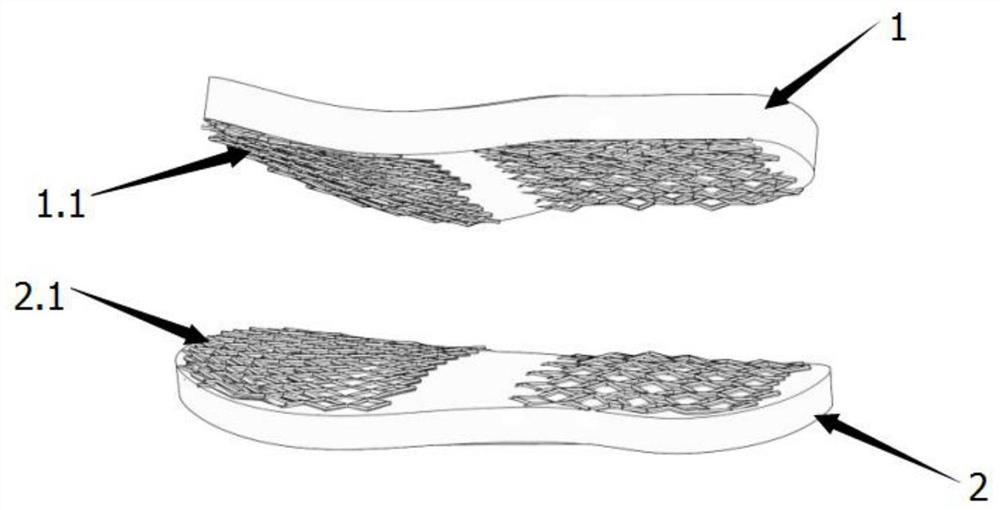

[0031] Among them, the specific structure and surface texture of the post-processing module are designed according to the requirements of the printed parts in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com