Explosive pre-buried hole punching equipment for building blasting

A technology of drilling equipment and pre-buried holes, which is used in blasting, stone processing equipment, stone processing tools, etc., can solve the problems of inability to adapt to construction conditions, low efficiency, and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

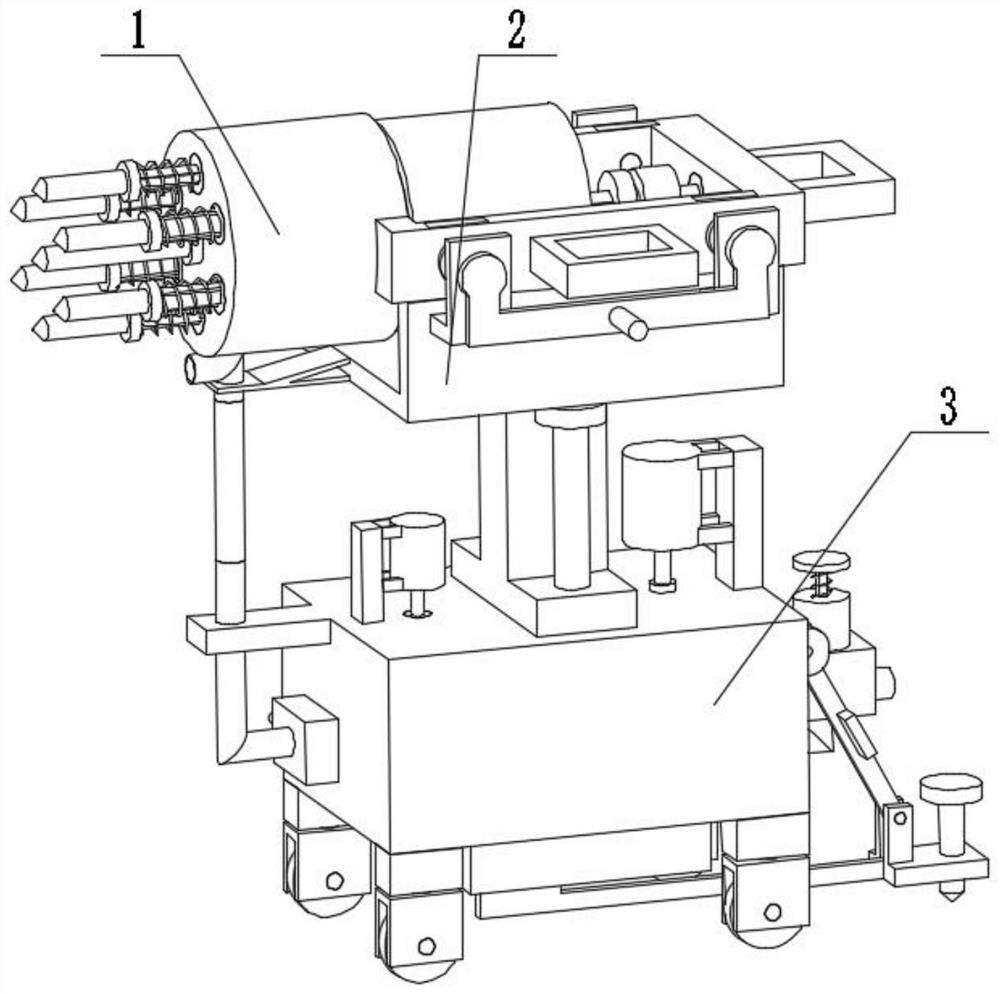

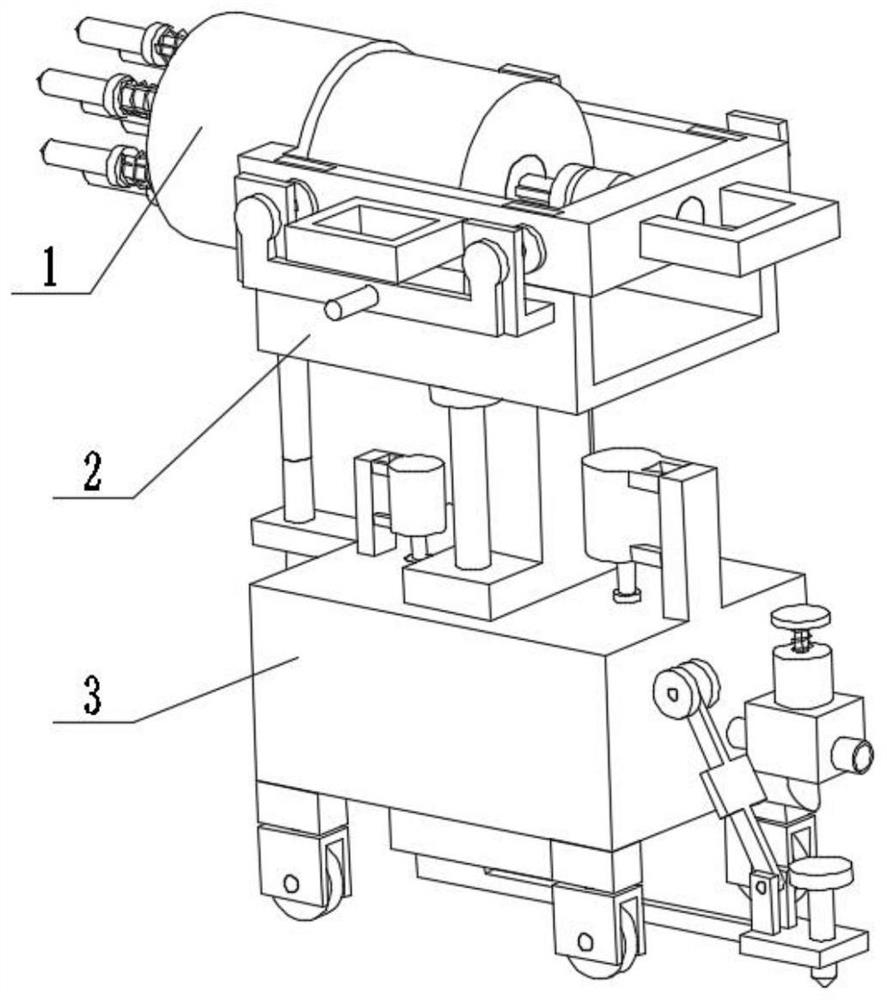

[0029] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 Describe this embodiment, the present invention relates to a kind of punching equipment, more specifically a kind of drilling equipment for pre-embedded holes with explosives for construction blasting, including a detachable punching device 1, a height variable bracket mechanism 2, a car body mechanism 3. The equipment can drill multiple holes at the same time, the equipment can be switched to single-hole mode, the equipment can be disassembled and used, the equipment can reduce dust, and the equipment can assist in drilling.

[0030] The detachable punching device 1 is connected with a height-variable bracket mechanism 2 , and the height-variable bracket mechanism 2 is connected with a vehicle body mechanism 3 .

specific Embodiment approach 2

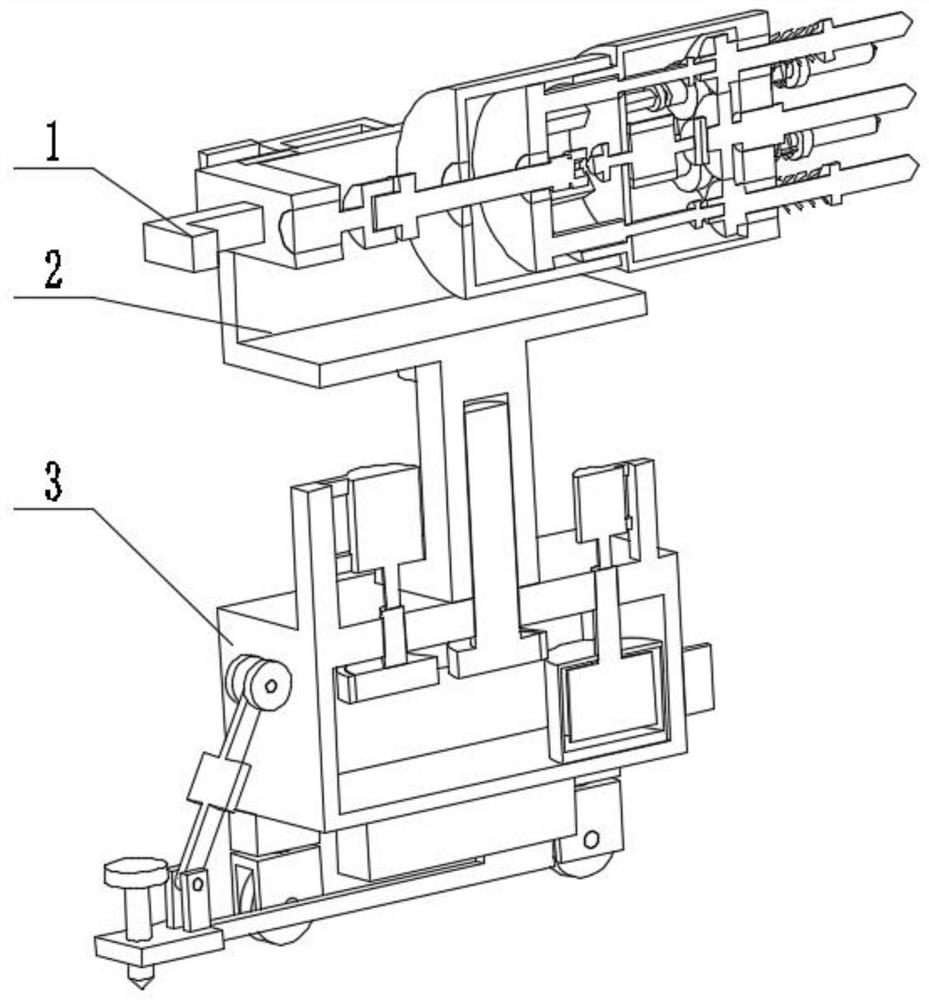

[0032] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 This embodiment will be described. This embodiment will further describe the first embodiment. The detachable drilling device 1 includes a central drill bit 1-1, an edge drill bit 1-2, a protruding shaft 1-3, a spring 1-4, Shaft with hole 1-5, shell 1-6, side support frame 1-7, card slot 1-8, limit hole 1-9, sleeve with internal thread 1-10, shaft with protrusion I1-11, connection Head 1-12, hydraulic rod 1-13, hydraulic cylinder 1-14, handle 1-15, gear 1-16, connector I1-17, stepped square column 1-18, square hole 1-19, hollow shaft 1- 20. Threaded seat 1-21, shaft with hole I1-22, shaft with hole II1-23, switching head 1-24, matching groove 1-25, connecting shaft 1-26, double output shaft motor 1-27, motor support 1-28, coupling 1-29, central gear 1-30, eccentric wheel 1-31,...

specific Embodiment approach 3

[0034] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 Describe this embodiment, this embodiment will further explain the first embodiment, the height variable bracket mechanism 2 includes a belt 2-1, a pulley 2-2, a screw 2-3, a lifting seat 2-4, and a light hole 2-5, pipe support 2-6, bracket body 2-7, seat with hole 2-8, limit rod 2-9, limit plate with square column 2-10, spring I2-11, pull seat 2-12 , with square hole bending support 2-13, servo motor 2-14, belt shaft motor pulley 2-15, threaded hole 2-16, including belt 2-1 and pulley 2-2 friction connection, pulley 2-2 and wire The bar 2-3 links to each other, the leading screw 2-3 is threadedly connected with the threaded hole 2-16 arranged on the riser 2-4, the riser 2-4 is provided with a light hole 2-5, and the pipe support 2-6 Connected with the bracket body 2-7, the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com