Automatic punching device for battery manufacturing

A punching device and battery technology, applied in the direction of battery pack parts, circuits, electrical components, etc., can solve problems such as bending, high scrapping rate of battery shells, and batteries that cannot be loaded normally, so as to achieve strong pressure resistance and maintain integrity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

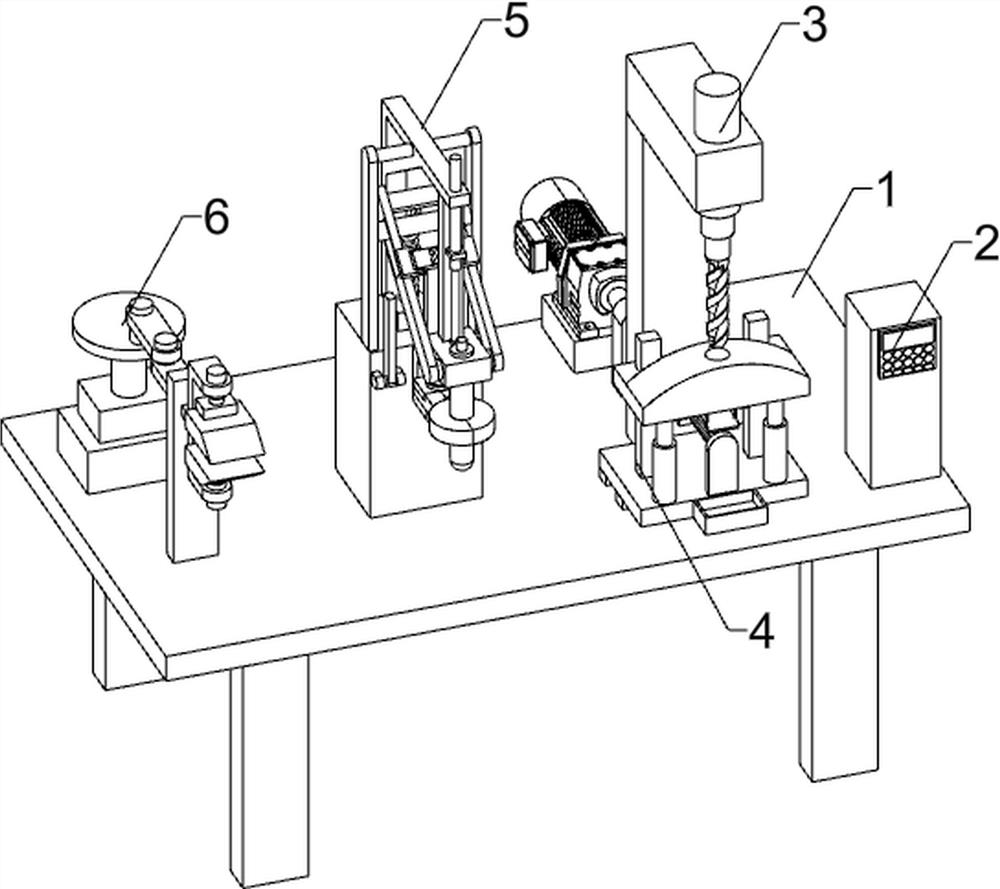

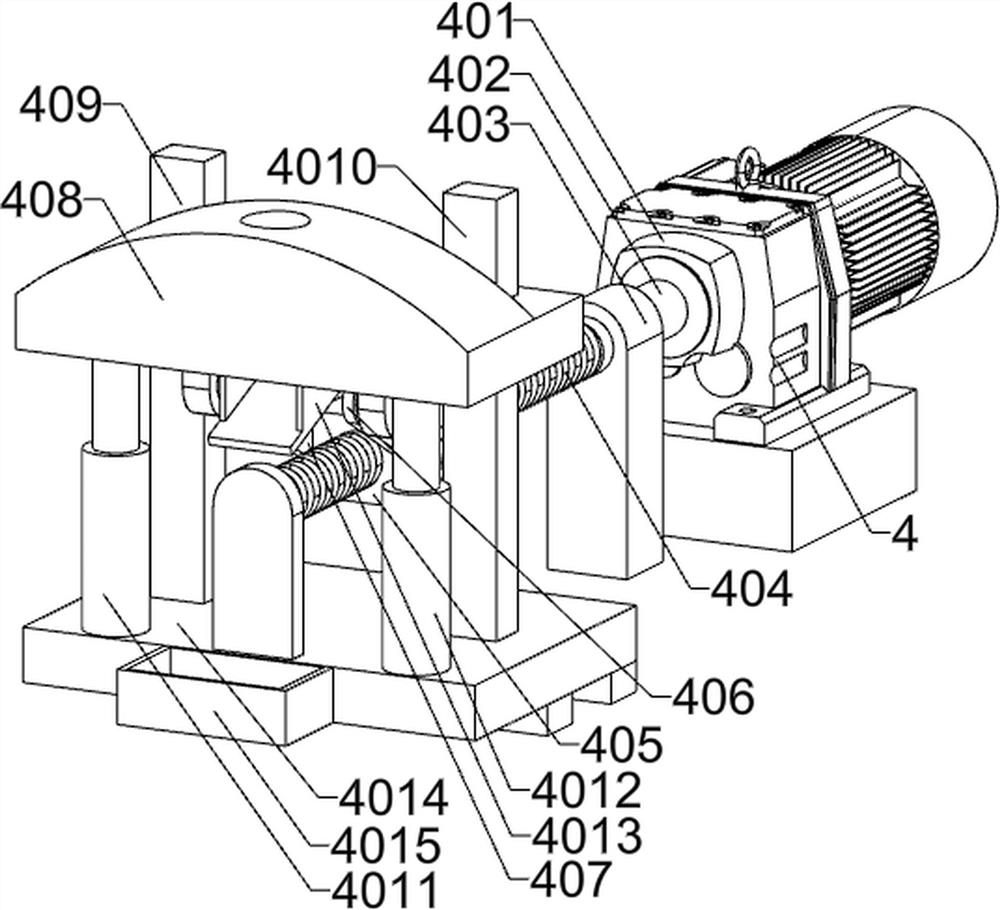

[0023] An automatic punching device for battery manufacturing, such as Figure 1-7 As shown, it includes a working machine board 1, an operation control panel 2, an electric telescopic electric drill 3, a drilling system 4, a repair system 5 and a burr removal system 6; the top of the working machine board 1 is connected with the operation control screen 2; the working machine board The top of 1 is connected with the electric telescopic electric drill 3; the top of the working machine board 1 is connected with the punching system 4; the top of the working machine board 1 is connected with the repair system 5; the top of the working machine board 1 is connected with the burr removal system 6.

[0024] When using the automatic punching device for battery manufacturing, firstly fix the device stably on the working plane, then connect the external power supply and turn on the operation control panel 2, then position the battery square shell with the opening facing the punching syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com