A cross wedge rolling mill for large axle rapid replacement of roll die

A cross wedge rolling mill, fast technology, applied in the direction of metal rolling stand, metal rolling mill stand, driving device for metal rolling mill, etc., can solve the problems of long replacement time, large size and weight, and high labor intensity of workers, etc. problem, to save time, speed up work efficiency and increase flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further illustrate the technical solutions of the present invention, the present invention will be further described below through examples.

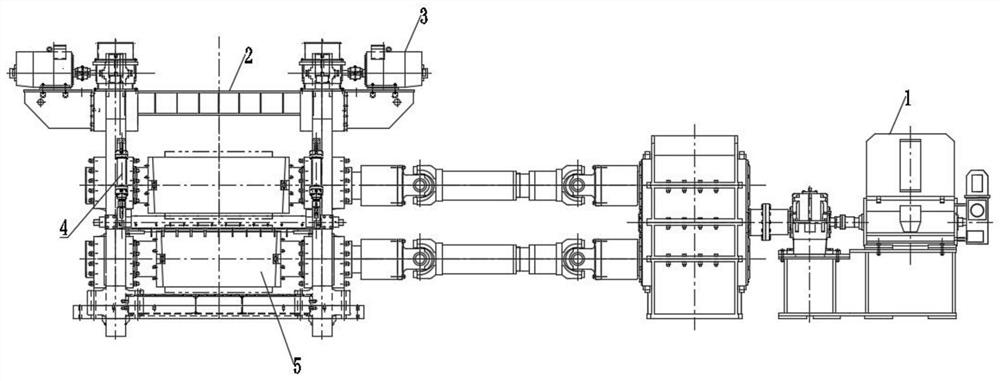

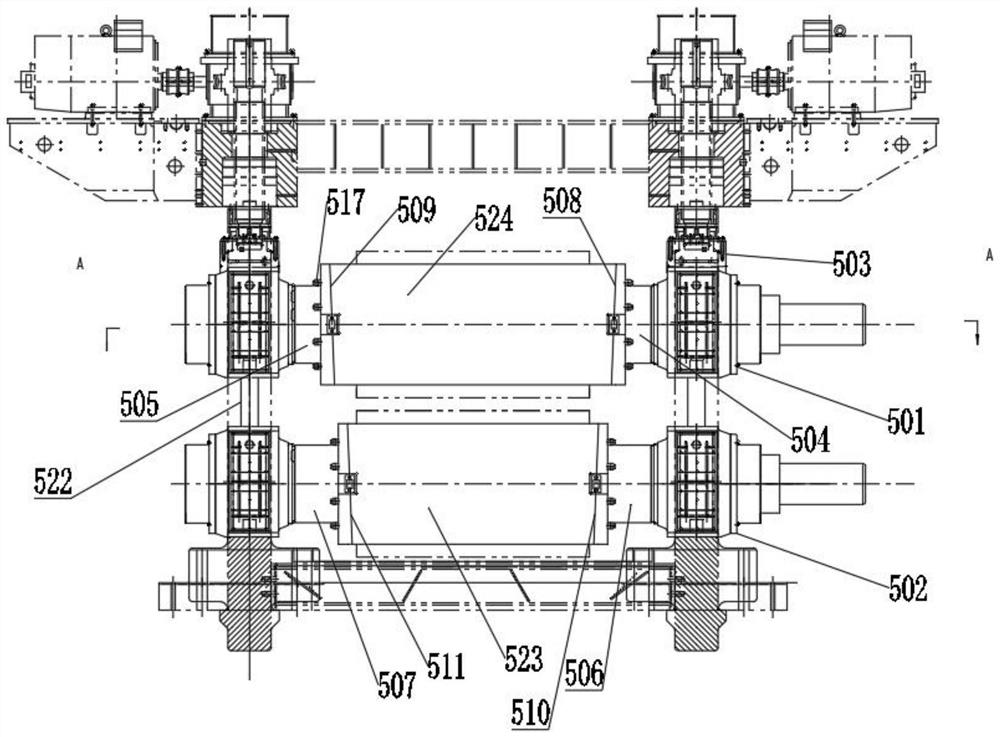

[0039] A large axle rapid replacement roll die cross wedge rolling mill, including a main transmission device 1, an archway 2, a worm gear and worm screw down 3, a roll system assembly 5 and a guide device 4;

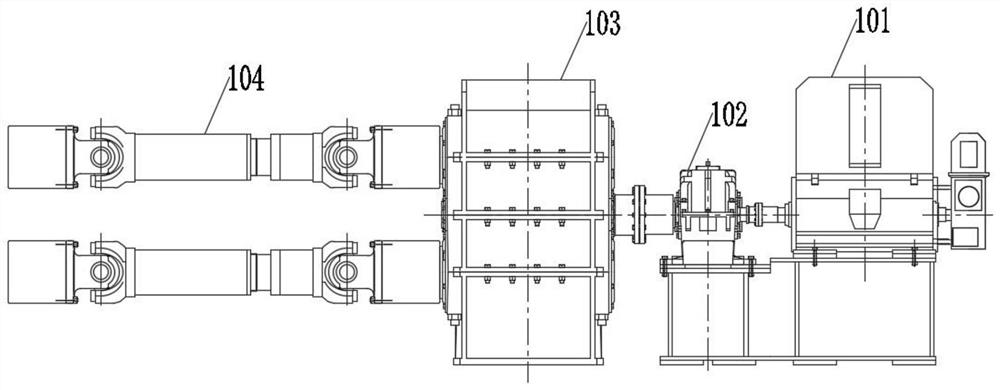

[0040] The main transmission device 1 includes a main transmission motor 101, a first-stage reducer 102 and a sub-gearbox 103, the output shaft of the main transmission motor 101 is connected with the input shaft of the first-stage reducer 102, and the first-stage deceleration The output shaft of the gear box 102 is connected with the input shaft of the differential case 103, and the two output shafts of the differential case 103 are respectively connected with the upper transmission side journal 504 and the lower transmission side journal 506 through the universal joint 104. connect;

[0041] The arch 2 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com