A printed circuit board product coding device and method

A technology for printed circuit boards and coding devices, which is applied in the directions of printed circuits, printed circuit manufacturing, and circuit board tool positioning, etc., which can solve the problem of directional sequential printed circuit board product coding, the inability to automatically encode, and the inability to automatically transmit printed circuits. Board products and other issues to achieve the effect of improving stability and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

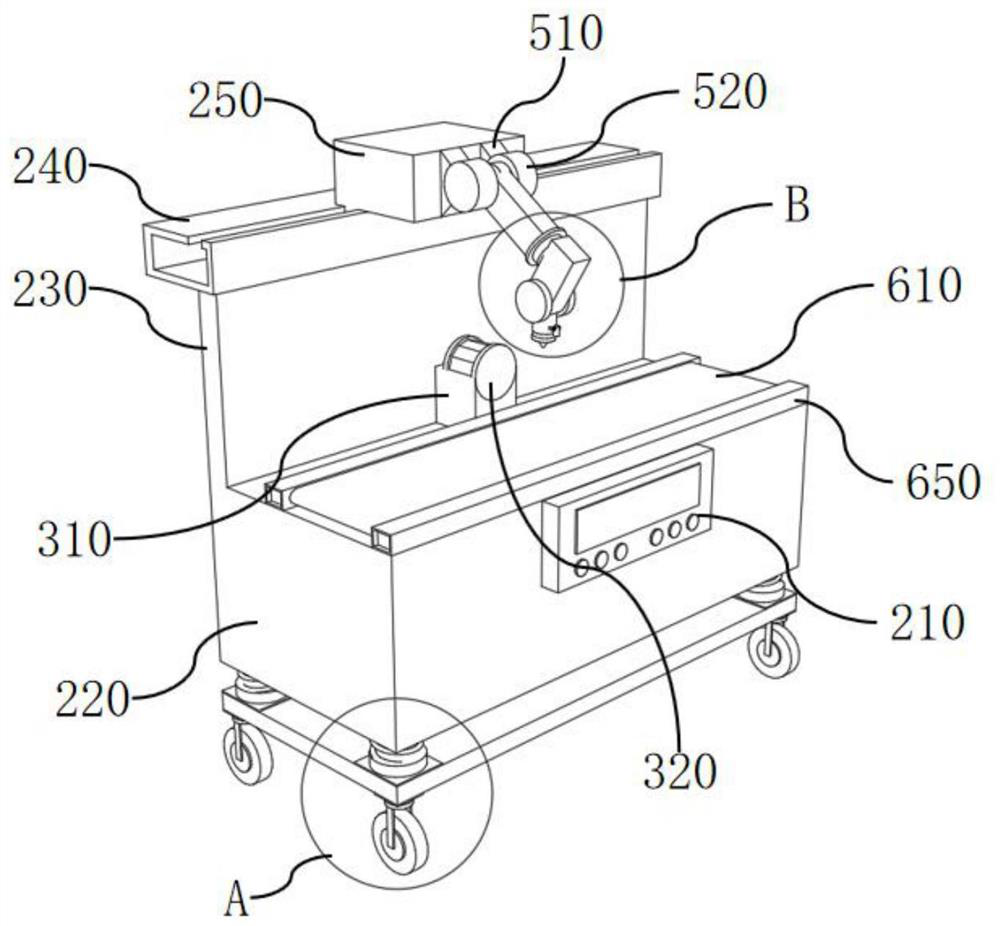

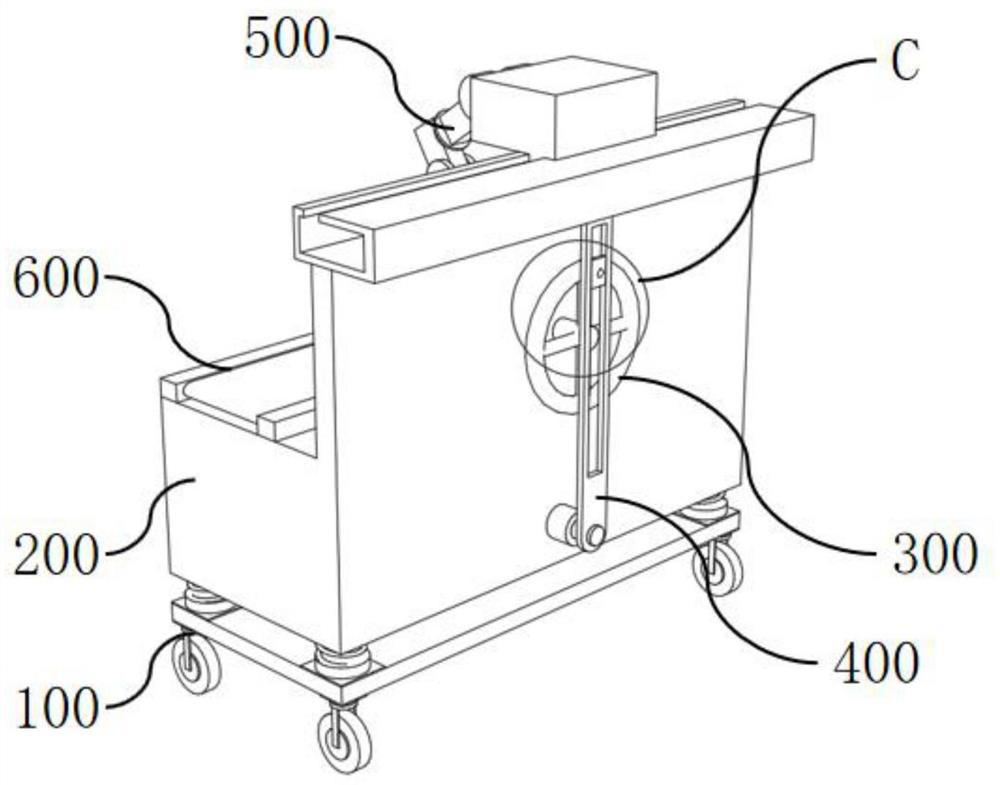

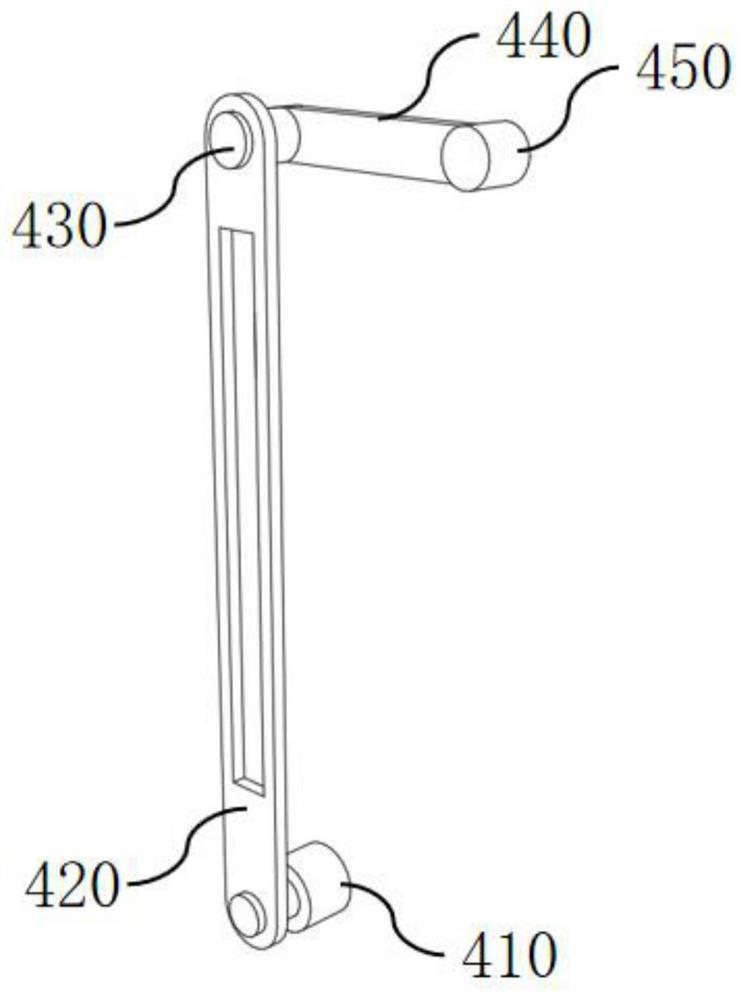

[0037] see Figure 1-7 As shown, the present invention is a printed circuit board product coding device, including a bottom mechanism 100, a main body mechanism 200, a driving mechanism 300, a transmission mechanism 400, an encoding mechanism 500 and a transmission mechanism 600, and the bottom mechanism 100 includes a shock absorbing spring 130, The main mechanism 200 includes the equipment box 220, the side plate 230 and the slider 250, the driving mechanism 300 includes the fixed block 310, the driving rod 330, the driving wheel 340 and the sliding block 360, and the transmission mechanism 400 includes the inner spiral tube 410, the transmission bar 420 and the rotating The pipe 450, the encoding mechanism 500 includes a fixing seat 510, the transmission mechanism 600 includes a fixing bar 650, one end of several damping springs 130 is connected to the lower surface of the equipment box 220, the side plate 230 is provided with a through hole, and one end of the driving rod 3...

Embodiment 2

[0046] A coding method of a printed circuit board product coding device, comprising the following steps:

[0047] Step 1: After placing the printed circuit board product on the surface of the conveyor belt 610, open the device through the control panel 210 to make the transmission motor 640 work, the transmission motor 640 drives the rotation roller 630 to rotate, and the rotation roller 630 drives the transmission belt 610 and the transmission roller 620 Rotate, the transmission belt 610 drives the printed circuit board products to automatically transmit;

[0048] Step 2: The driving motor 320 drives the driving rod 330 to rotate, the driving rod 330 drives the driving wheel 340 to rotate, the driving wheel 340 drives the rotating rod 350 to rotate, and the sliding block 360 converts the rotating motion of the rotating rod 350 into a sliding motion inside the transmission bar 420 Movement, the transmission bar 420 converts the sliding motion of the sliding block 360 into a pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com