Pre-lithiated tin-lithium alloy nanoparticles for lithium-sulfur batteries, preparation method and application

A nanoparticle, lithium-sulfur battery technology, applied in the field of lithium-ion batteries, can solve the problems of limited chemical adsorption, polysulfide shuttle effect, and material battery performance decline, to reduce the shuttle effect, improve the gram capacity of materials, and reduce stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The preparation and application of the prelithiated tin-lithium alloy nanocomposite lithium-sulfur positive electrode includes the following steps:

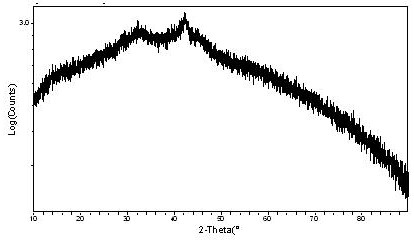

[0058] Weigh the elements of tin, lithium, cobalt, titanium, zinc and manganese according to the mass percentage of 70:10:25:3:5:5, put them into a vacuum melting furnace, and then introduce a high-speed 99.99% nitrogen gas through the aerosol method to prepare the components. Uniform tin-lithium alloy powder. The prepared tin-lithium alloy powder was placed in a stirring ball mill, and ball-milled for 50 hours under the protection of 99.99% nitrogen to prepare black amorphous tin-lithium alloy powder.

[0059] The prepared black amorphous tin-lithium alloy powder was added to single-wall carbon nanotube (SCNT, Single Wall Carbon Nanotube) at 5% by mass, and ball-milled for 50 hours under the protection of 99.99% nitrogen to prepare black powder.

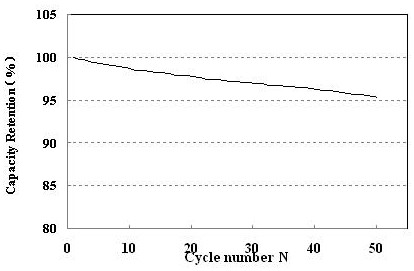

[0060] Mix the prepared mixed powder with elemental sulfur in a mass perce...

Embodiment 2

[0066] The preparation conditions of the prelithiated tin-lithium alloy nanocomposite lithium-sulfur positive electrode are the same as those in Example 1, the difference is: tin, lithium, cobalt and iron are weighed according to the mass percentage of 80:5:10:5, and the preparation is uniform in composition. tin-lithium alloy powder. The fabrication of other pole pieces and the assembly of the battery are the same as those of Example 1.

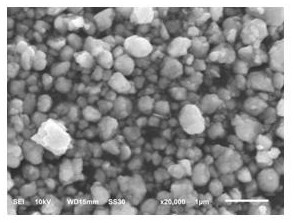

[0067] image 3 It is the SEM image of the amorphous tin-lithium alloy prepared in Example 2.

Embodiment 3

[0069] The preparation conditions of the pre-lithiated tin-lithium alloy nanocomposite lithium-sulfur positive electrode are the same as those in Example 1, the difference is: tin, lithium, cobalt and aluminum are weighed according to the mass percentage of 60:20:15:5, and the preparation is uniform in composition. tin-lithium alloy powder. The fabrication of other pole pieces and the assembly of the battery are the same as those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com