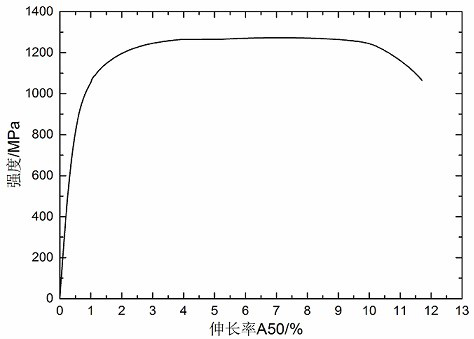

High-drawing high-reaming 1200MPa-grade cold-rolled strip steel and production method

A technology of cold-rolled strip steel and production methods, applied in the field of metallurgy, can solve the problems of reduced drawing performance and hole expansion performance, increase in strength, etc., and achieve improved drawing performance and hole expansion performance, refined grains, and high stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

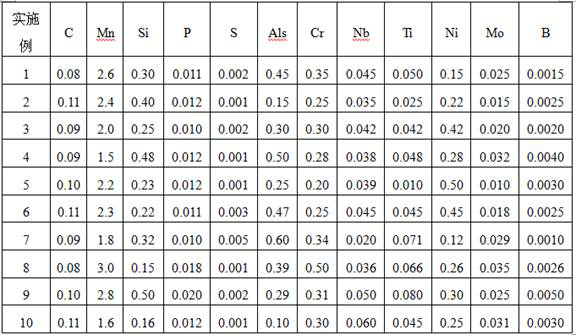

[0029] In this embodiment, a high-drawing and high-hole-expanding 1200MPa-grade cold-rolled steel strip has a thickness of 2.0 mm, its chemical composition and mass percentage are shown in Table 1, and its mechanical properties are shown in Table 2.

[0030] In this embodiment, a production method of high-drawing and high-hole-expanding 1200MPa grade cold-rolled steel strip includes continuous casting, heating, hot-rolling, cold-rolling, continuous annealing and smoothing processes, and the specific process steps are as follows:

[0031] (1) Continuous casting process: tundish temperature 1520°C, continuous casting casting speed 1.3m / min;

[0032] (2) Heating process: Heating with a walking heating furnace, the soaking temperature of the heating section of the continuous casting slab is 1240°C, and the total heating time is 180min;

[0033] (3) Hot rolling process: finishing rolling temperature is 860°C, coiling temperature is 640°C;

[0034] (4) Cold rolling process: cold ro...

Embodiment 2

[0039] In this implementation, a high-drawing and high-hole-expanding 1200MPa-grade cold-rolled steel strip has a thickness of 1.0mm. Its chemical composition and mass percentage are shown in Table 1, and its mechanical properties are shown in Table 2.

[0040] In this embodiment, a production method of high-drawing and high-hole-expanding 1200MPa grade cold-rolled steel strip includes continuous casting, heating, hot-rolling, cold-rolling, continuous annealing and smoothing processes, and the specific process steps are as follows:

[0041] (1) Continuous casting process: tundish temperature 1510°C, continuous casting casting speed 1.2m / min;

[0042] (2) Heating process: Heating by a walking heating furnace, the soaking temperature of the heating section of the continuous casting slab is 1290°C, and the total heating time is 190min;

[0043] (3) Hot rolling process: the finish rolling temperature is 900°C, and the coiling temperature is 655°C;

[0044] (4) Cold rolling proces...

Embodiment 3

[0048] In this embodiment, a high-drawing and high-hole-expanding 1200MPa-grade cold-rolled steel strip has a thickness of 1.6 mm, its chemical composition and mass percentage are shown in Table 1, and its mechanical properties are shown in Table 2.

[0049] In this embodiment, a production method of high-drawing and high-hole-expanding 1200MPa grade cold-rolled steel strip includes continuous casting, heating, hot-rolling, cold-rolling, continuous annealing and smoothing processes, and the specific process steps are as follows:

[0050] (1) Continuous casting process: tundish temperature 1530°C, casting speed 1.4m / min;

[0051] (2) Heating process: Heating with a walking heating furnace, the soaking temperature of the heating section of the continuous casting slab is 1300°C, and the total heating time is 240min;

[0052] (3) Hot rolling process: the finish rolling temperature is 880°C, and the coiling temperature is 670°C;

[0053] (4) Cold rolling process: cold rolling reduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com