Vinasse stacking fermentation material scattering device, system and method

A stacking fermentation and material spreading device technology, applied in the field of wine making, to achieve the effect of ensuring uniformity, reducing labor intensity of workers, and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

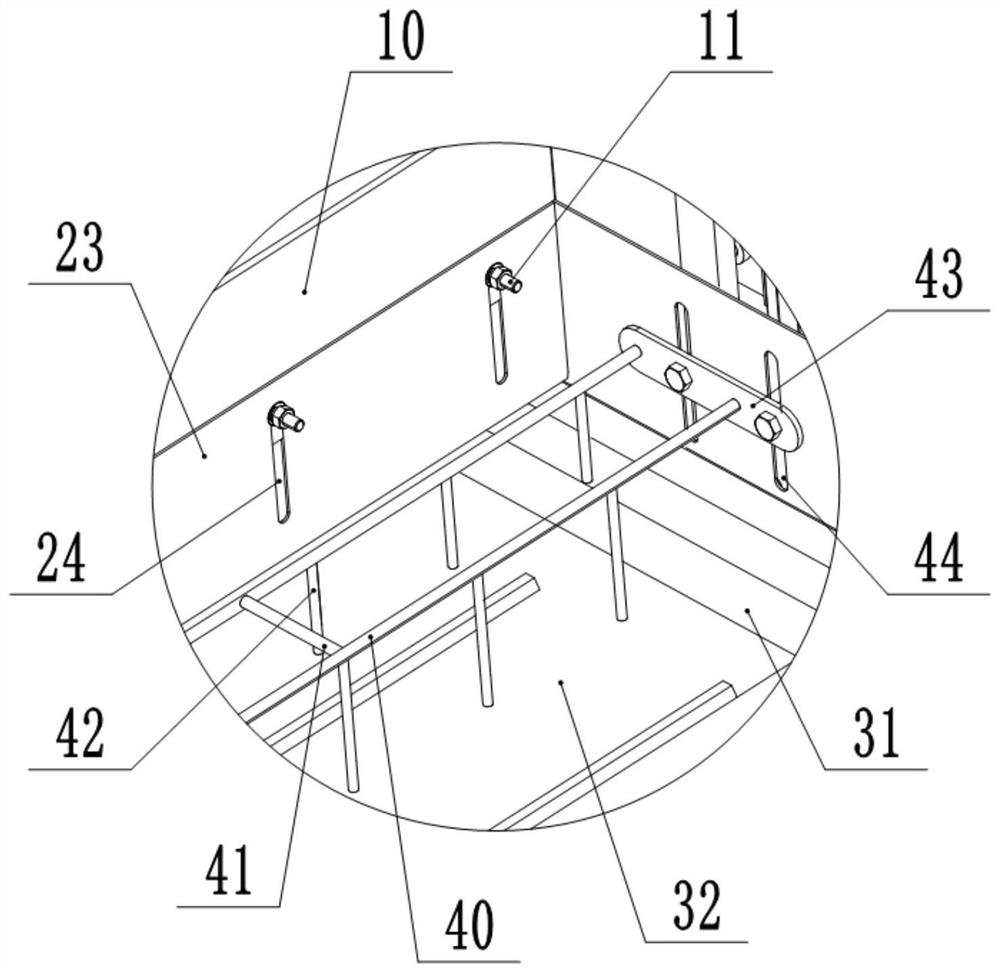

[0039] Such as figure 1 , figure 2 and image 3 As shown, a distiller's grain accumulation fermentation spreading device includes a belt conveyor 3 and a hopper 10 connected above the frame 30 of the belt conveyor 3. The bottom of the hopper 10 is open and conveyed with the belt conveyor 3. The surfaces 32 are opposite, and the front end surface of the hopper 10 is provided with an opening for the conveying surface 32 of the belt conveyor 3 to send out the material from the inside of the hopper 10 .

[0040]During the specific use of this device, due to the limitation of the opening, the thickness of the distiller's grains brought out from the hopper 10 through the transmission surface 32 of the belt conveyor 3 is consistent, and at the same time, under the limitation of the size of the bottom of the hopper 10, it is located on the transmission surface. The distiller’s grains on the 32 have the same width, so that the distiller’s grains in the hopper 10 are evenly brought o...

Embodiment 2

[0042] On the basis of Example 1, an adjusting plate 23 for controlling the thickness of the distiller's grains is connected to the opening, and the adjusting plate 23 is provided with a strip-shaped through hole A24, and the long-diameter end of the strip-shaped through-hole A24 is perpendicular to The transmission surface 32 of the belt conveyor 3 is fixedly connected with a connecting rod 11 on the front end of the hopper 10, and the end of the connecting rod 11 far away from the hopper 10 passes through the strip-shaped through hole A24 and is connected with the lock nut A; There is a rake comb 4, and the rake comb 4 is fixedly connected with the frame 30 of the belt conveyor 3; the two ends of the rake comb 4 are respectively fixed to the corresponding end faces of the frame 30 of the belt conveyor 3 through a connecting plate 43 Connect, the frame 30 of the belt conveyor 3 is provided with a bar-shaped through-hole B44 opposite to the connecting plate 43, and the long-dia...

Embodiment 3

[0046] Such as Figure 4 As shown, a distiller's grain accumulation fermentation spreading system includes a distiller's grain accumulation fermentation spreading device and a multi-axis motion control platform 60 for operating the movement of the distiller's grain accumulation fermentation spreading device, and the distiller's grain accumulation fermentation spreading device is claimed in claims 1-6 According to any one of the distiller's grain accumulating fermentation and spreading device, the execution end of the multi-axis motion control platform 60 is fixedly connected with the frame of the distiller's grain accumulating fermentation and spreading device.

[0047] In the specific use process of this device, the multi-axis motion control platform 60 can be selected from a robot. Due to the multi-degrees of freedom of the multi-axis motion control platform 60, the attitude adjustment can be performed in the process of spreading materials, which is controlled by the multi-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com