A kind of sealing slurry for assembly type construction in winter and preparation method thereof

A prefabricated and slurry technology, which is applied in the field of prefabricated buildings, can solve problems such as high maintenance costs, threats to project quality and safety, and influence on the strength of sealing grout, and achieve good bonding performance, good crack resistance, plasticity and Good effect of thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The sealing slurry for prefabricated construction in winter in this embodiment is composed of the following components in parts by weight:

[0027] 35 parts of P·O52.5R ordinary Portland cement, 5 parts of fast-hardening sulfoaluminate cement, 15 parts of heavy calcium ultrafine powder, 30 parts of 40-70 mesh river sand, 15 parts of 70-140 mesh river sand , 0.02 part of azodicarbonamide, 0.08 part of sodium lignosulfonate, 0.08 part of tartaric acid, 0.08 part of sodium gluconate, 0.05 part of lithium carbonate, 0.045 part of hydroxypropyl methyl cellulose ether, anti-saponification redispersible vinyl acetate / 0.2 part of ethylene copolymer rubber powder, 0.1 part of calcium stearate, 0.1 part of German Mingling Chemical P803 silicone defoamer, and 0.15 part of sodium nitrate.

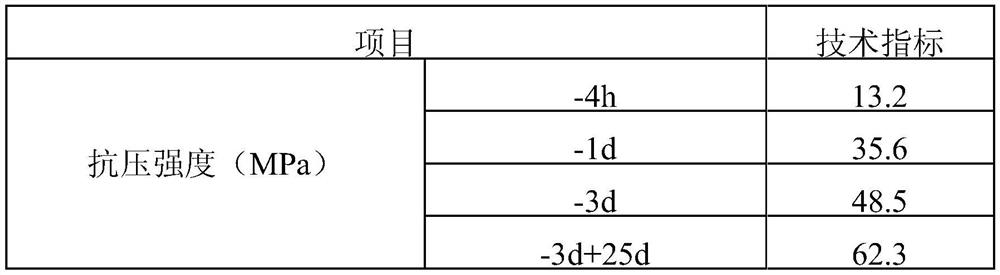

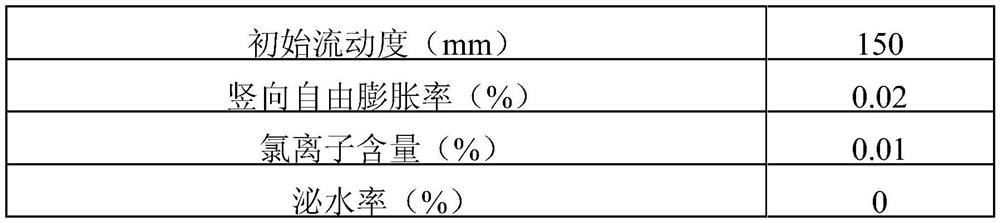

[0028] After mixing the above materials evenly, put them in a -5℃ environment for 24 hours, and at -5℃ extreme environment, according to a water-material ratio of 0.14, use a 0℃ ice-water mixt...

Embodiment 2

[0034] The sealing slurry for prefabricated construction in winter in this embodiment is composed of the following components in parts by weight:

[0035] 35 parts of 52.5 magnesium phosphate cement, 8 parts of fast-hardening sulfoaluminate cement, 12 parts of microbead fly ash, 30 parts of 40-70 mesh river sand, 15 parts of 70-140 mesh river sand, 0.02 part of azodicarbonamide 0.08 part of sodium lignosulfonate, 0.1 part of boric acid, 0.1 part of sodium gluconate, 0.08 part of lithium carbonate, 0.05 part of hydroxypropyl methyl cellulose ether, 0.2 part of anti-saponification redispersible vinyl acetate / ethylene copolymer powder , 0.1 part of calcium stearate, 0.1 part of German Mingling Chemical P803 silicone defoamer, 0.2 part of sodium nitrate.

[0036] After mixing the above materials evenly, put them in a -5℃ environment for 24 hours, and at -5℃ extreme environment, according to a water-material ratio of 0.14, use a 0℃ ice-water mixture to stir, and the measured indica...

Embodiment 3

[0042] The sealing slurry for prefabricated construction in winter in this embodiment is composed of the following components in parts by weight:

[0043] 35 parts of P·O52.5R ordinary Portland cement, 15 parts of fast-hardening sulfoaluminate cement, 5 parts of S95 superfine slag powder, 35 parts of 40-70 mesh river sand, 10 parts of 70-140 mesh river sand part, 0.015 part of azodicarbonamide, 0.08 part of sodium lignosulfonate, 0.15 part of tartaric acid, 0.05 part of sodium gluconate, 0.15 part of lithium carbonate, 0.035 part of hydroxypropyl methylcellulose ether, anti-saponification redispersible acetic acid 0.25 part of ethylene / ethylene copolymer rubber powder, 0.1 part of zinc stearate, 0.2 part of German Mingling Chemical P803 silicone defoamer, and 0.3 part of sodium nitrite.

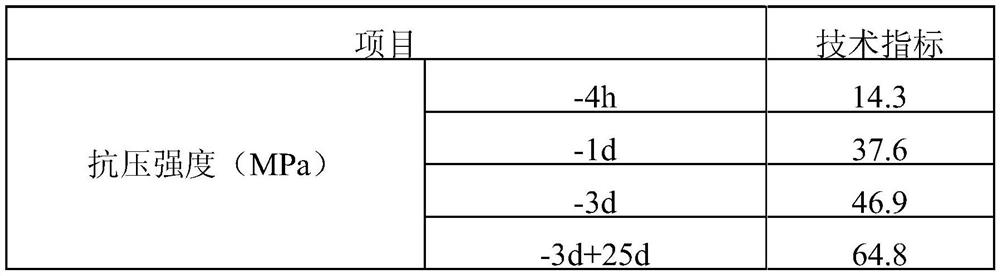

[0044] After mixing the above materials evenly, put them in a -10℃ environment for 24 hours. Under the extreme environment of -10℃, according to a water-material ratio of 0.14, use a 0℃ ice-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com