Traction machine with long service life

A traction machine and life-span technology, which is applied in the field of traction machines, can solve the problems of increasing the overall length of the rotor shaft, increasing the processing cost and difficulty of the rotor shaft, and increasing the cost of equipment, so as to improve the working stability and service life, reduce the The overall shape and equipment cost, and the effect of avoiding uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

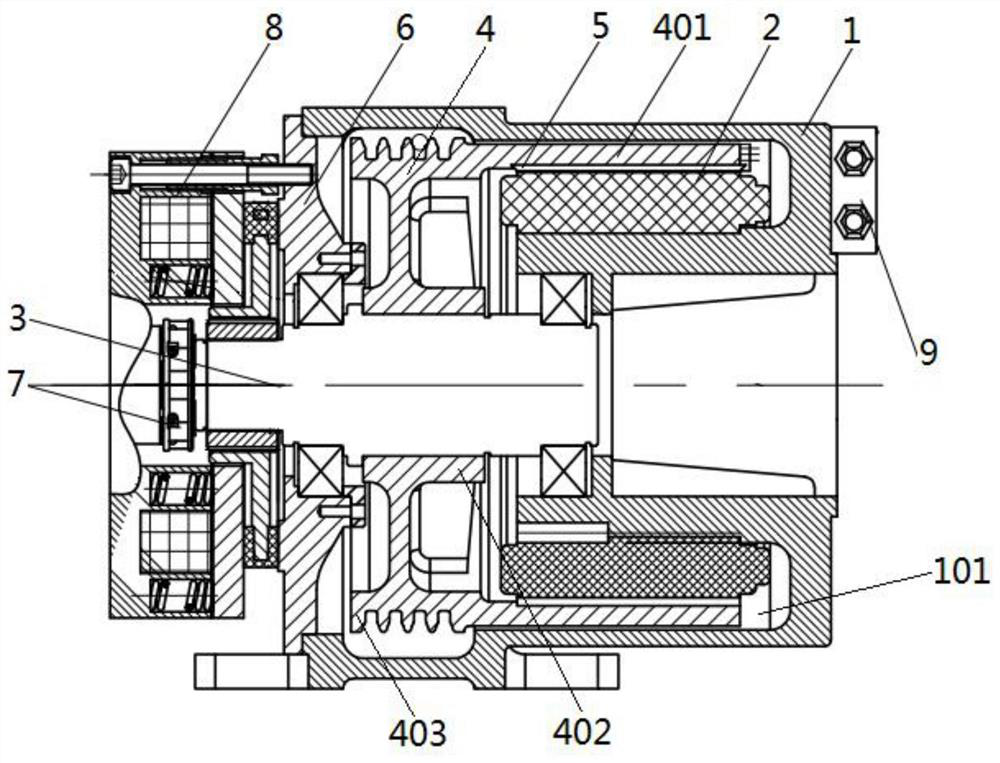

[0022] Example. Traction machine with long service life, constituted as figure 1 As shown, it includes a machine base 1, a stator core 2, a rotor shaft 3 and a traction wheel 4, wherein the stator core 2 is a stator core with windings, and the two sides of the rotor shaft 3 are connected to the machine base 1 through bearing rotation, The middle part of the rotor shaft 3 is connected to the traction sheave 4 , and the outer upper end of the traction sheave 4 extends into the base 1 and is provided with a rotor yoke 401 , which is integrally formed with the traction sheave 4 .

[0023] One side of the base 1 is provided with an annular iron core chamber 101. The cross-sectional shape of the iron core chamber 101 is U-shaped. The stator core 2 is sleeved on the inner ring of the iron core chamber 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com