An automated equipment for culvert pipe production

A technology of culverts and equipment, applied in the field of automated equipment, can solve the problems of reducing the normal service life of culverts, consuming a lot of manpower and material resources, and breaking culverts, so as to achieve the effects of reducing manpower and material resources, facilitating disassembly, and increasing connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

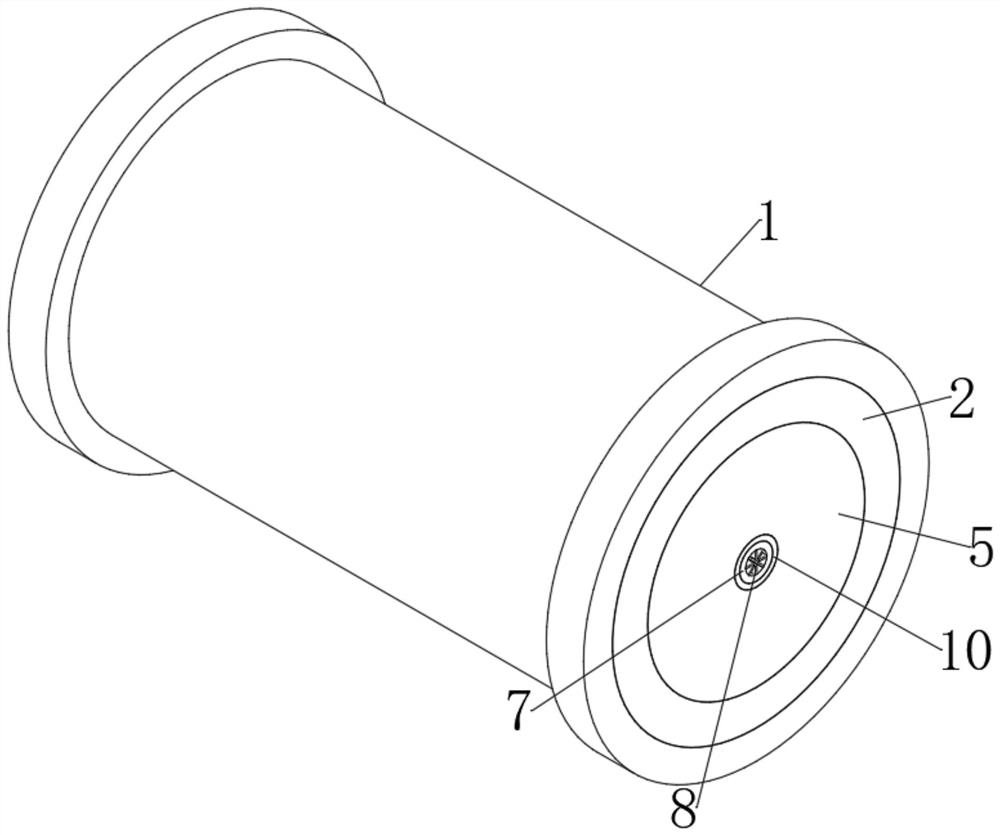

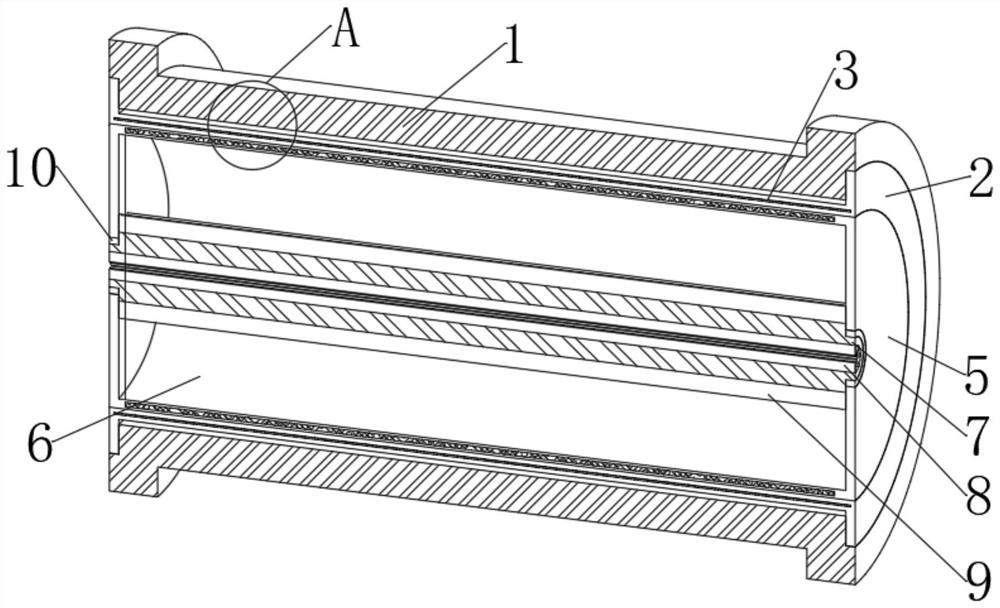

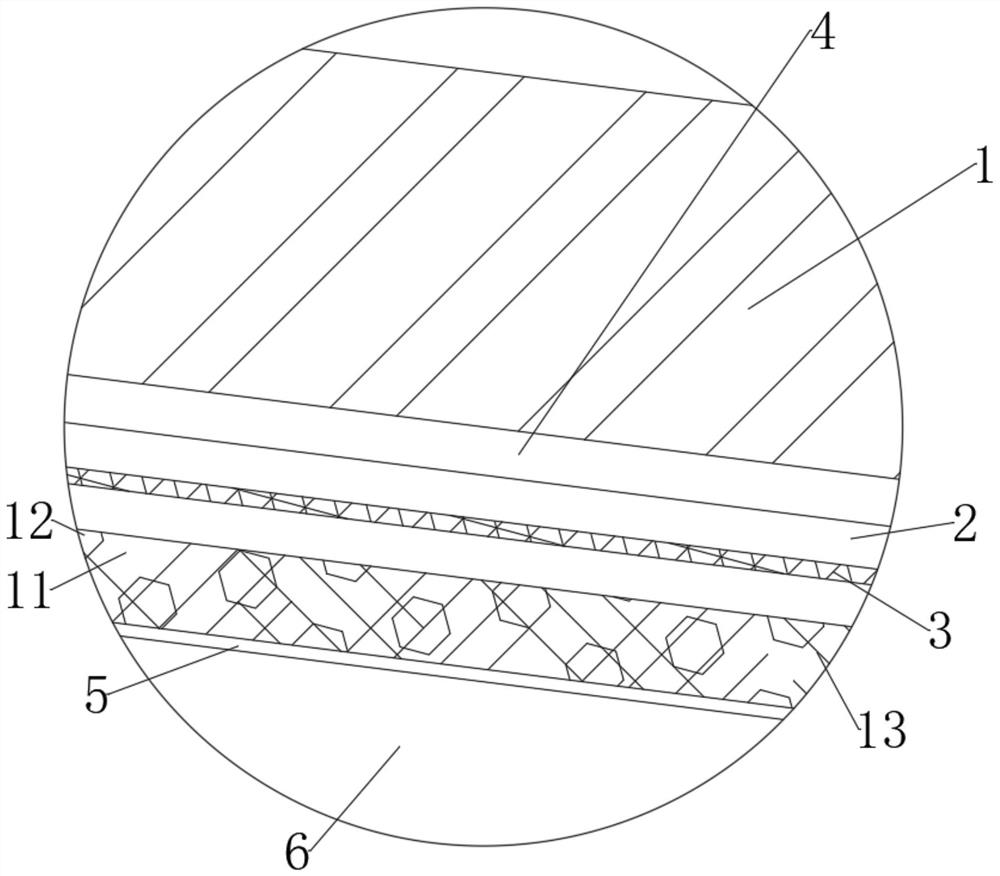

[0037] see Figure 1-3, an automatic equipment for culvert production, comprising an attachment pad 2 inserted in a cement culvert main body 1, the attachment pad 2 is matched with the cement culvert main body 1, and the attachment pad 2 is embedded with a reinforcing mesh 3 that matches itself, The reinforcing mesh 3 always has a tendency to shrink. A repair material block 4 is connected between the cement culvert main body 1 and the attachment pad 2, and the repair material block 4 is fixedly connected with the attachment pad 2. The repair material block 4 is preferably liquid glass, that is, nano-dioxide. The mixture of silicon and alcohol is filled in the film, the attachment pad 2 is inserted with an expansion pad 5 that matches itself, an expansion cavity 6 is drilled in the expansion pad 5, and the expansion cavity 6 is filled with nitrogen at a standard atmospheric pressure. A heat-conducting pipe 7 is inserted in the cavity 6. The heat-conducting pipe 7 is in the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com