Automatic one-way valve element assembling machine

An automatic group, one-way valve technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing elasticity and load capacity, manual assembly defects, leakage, inability to adapt, etc., to achieve the effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

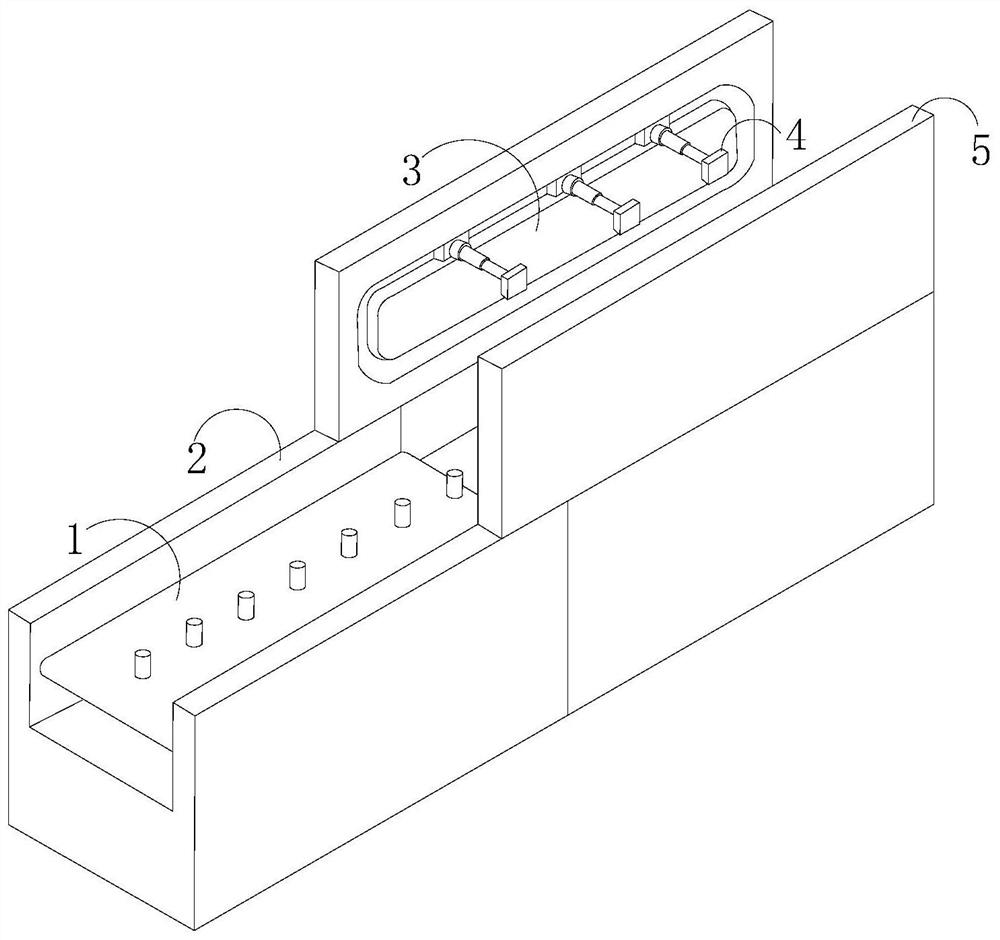

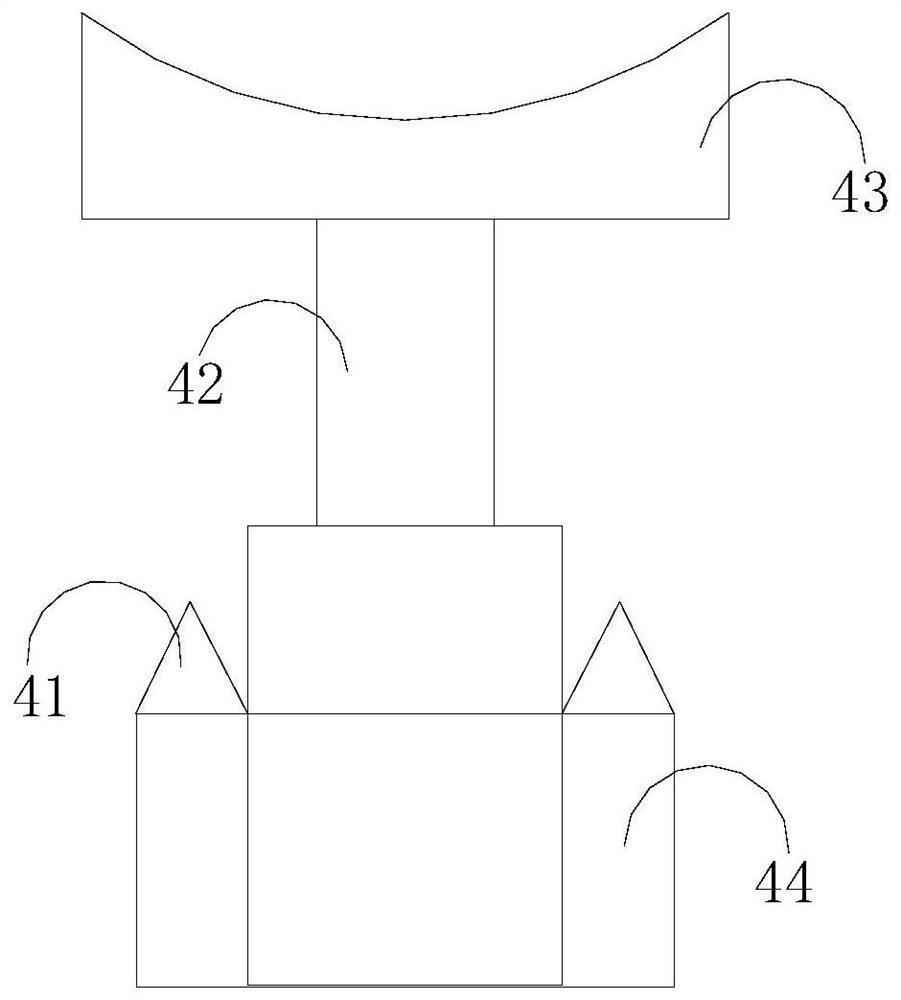

[0026] Such as Figure 1-Figure 3 As shown, the present invention provides an automatic assembling machine for a one-way valve core, the structure of which includes a conveyor belt 1, a base 2, a fixed plate 3, claws 4, and a side plate 5, and the conveyor belt 1 is fixedly connected to one end of the base 2 , the other end of the base 2 is welded with two side plates 5, the inside of the side plate 5 is welded with a fixed plate 3, and a claw 4 is installed on the fixed plate 3, and the claw 4 includes buckles 41. Connecting column 42, clamping mechanism 43, card edge handle 44, said button teeth 41 are provided with two, respectively fixedly connected on both sides of card edge handle 44, and the middle part of said card edge handle 44 is inserted and connected with connecting column 42, and the card edge 44 is socketed and connected between the fixed plate 3 and the side plate 5, and the clamping mechanism 43 is installed on the top of the connecting column 42, and the clam...

Embodiment 2

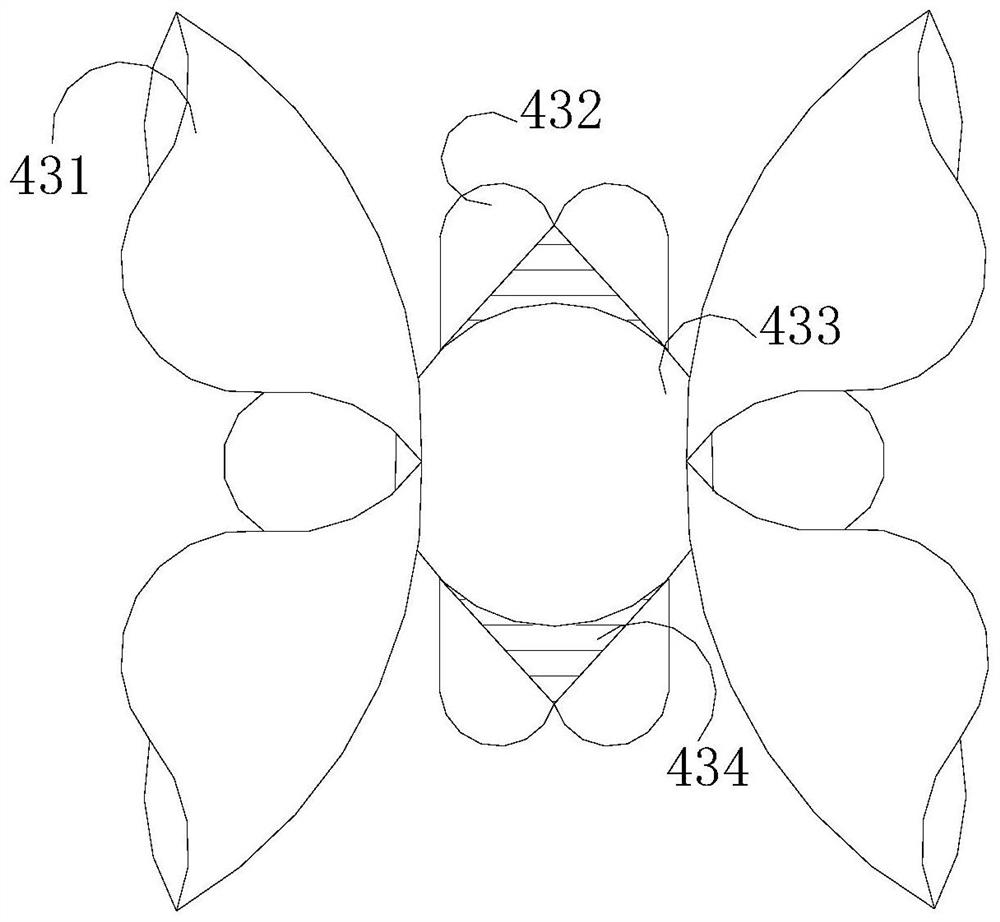

[0028] Such as Figure 4-Figure 7 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The pipe collar 431 includes a hinge 311, a top block 312, an outer limiting piece 313, a sloping plate 314, and a collar 315. The hinge 311 is fixedly connected to one end of the inclined plate 314, and the other end of the inclined plate 314 is hingedly connected to the outer circumference of the collar 315. Both sides of the top block 312 are provided with outer limiting pieces 313. The external indirect cooperation of the inlet body 434 is convenient for the indirect auxiliary pipe collar 431 to deform toward both sides of the spring, and the additional internal force generated ensures the bearing capacity of the overall structure. Strip 333, pressure bag 334, booster 335, socket cavity 336, the card point hook 331 is a semicircular structure, and is engaged with the inner circumference of the collar 315 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com