Sample crushing and screening device for soil detection

A soil detection and screening device technology, applied in the direction of sieves, applications, household appliances, etc., can solve the problems of sticking to stones, poor screening effect, affecting the filterability of screening nets, etc., and achieves good heating effect and good contact. , improve the effect of filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

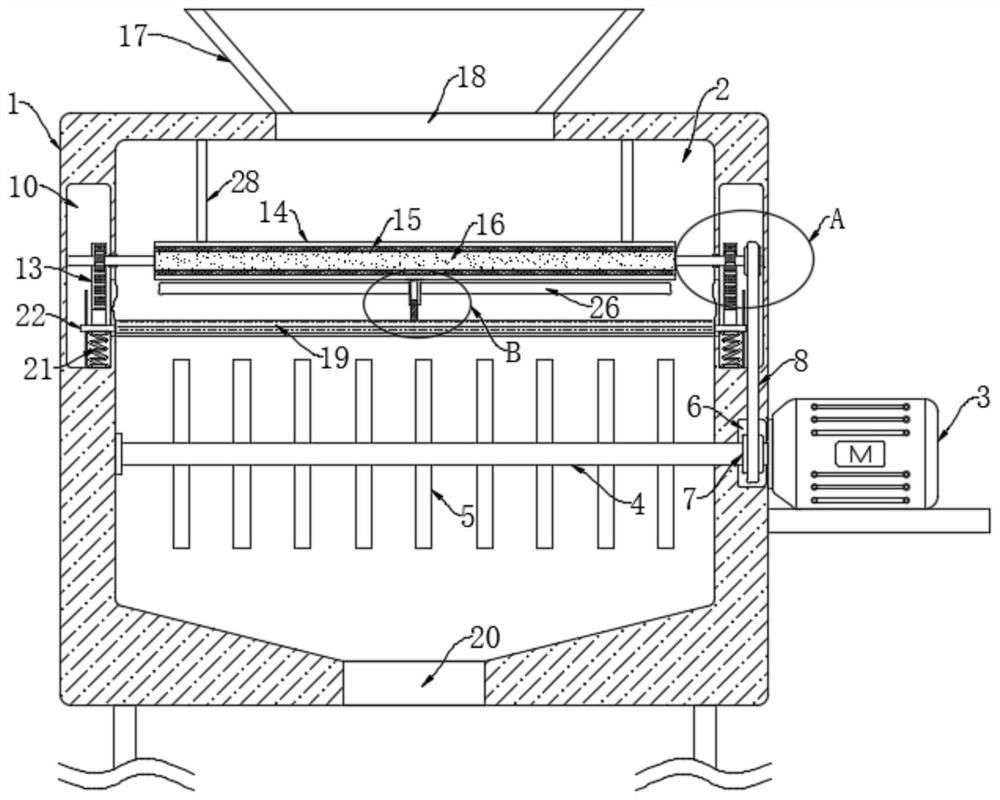

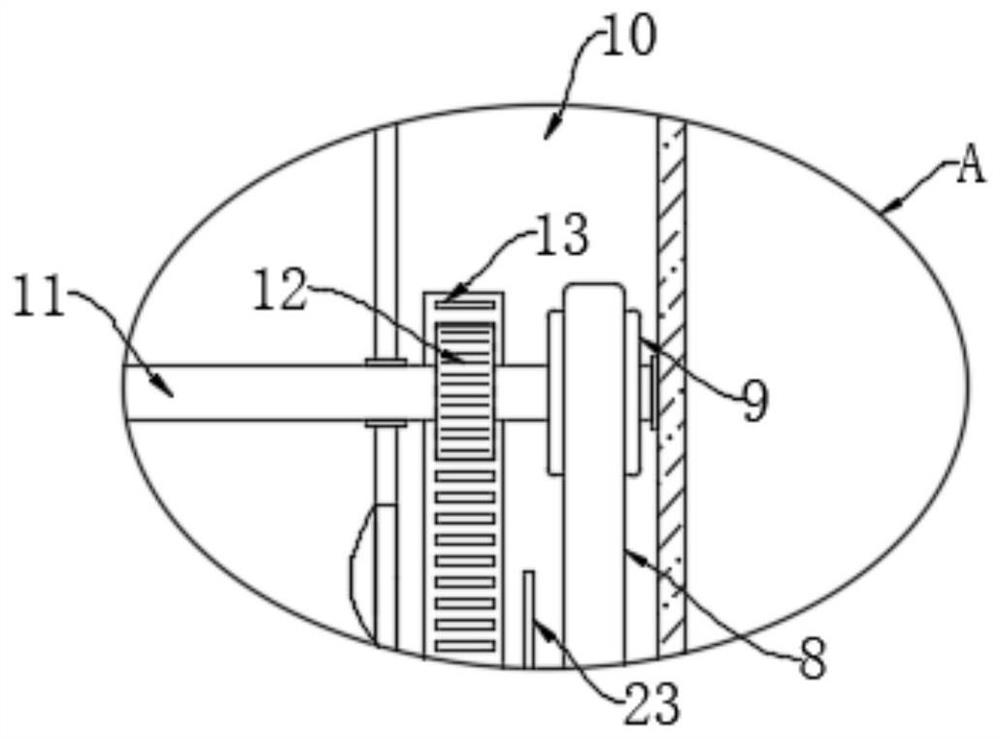

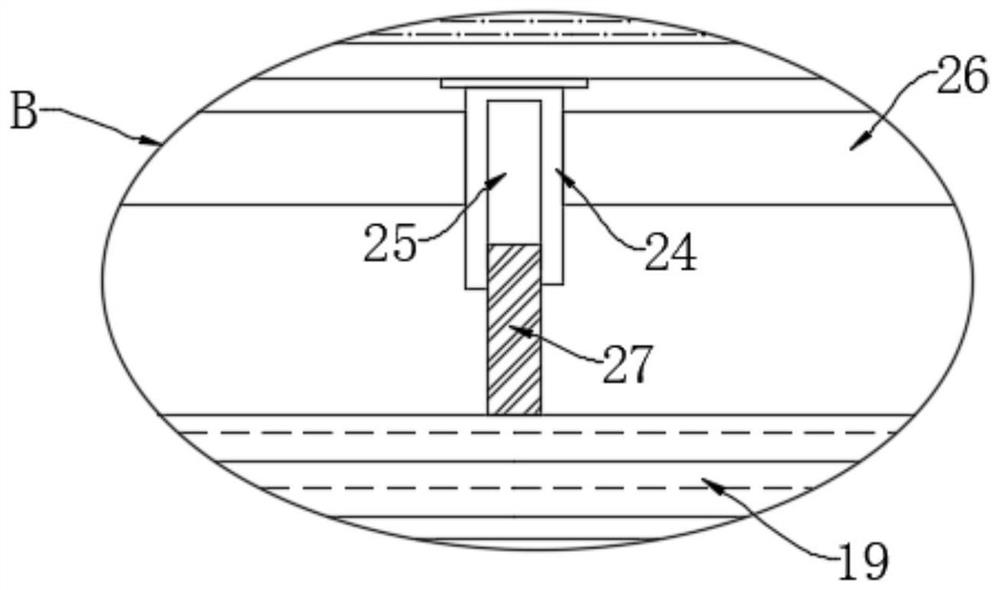

[0027] Refer Figure 1-4 A sample milling screen for soil detection, including screening box 1, and a plurality of support rods are fixedly coupled to the lower end of the screening box 1, and the screen box 1 is provided with a screening chamber 2, and the top of the best screening chamber 2 is fed by feed. The mouth 18 is connected to the outside, the upper end of the screening box 1 is mounted with the feed hopper 17, the lower end of the feed hopper 17 is connected to the feed opening 18, and the feed hopper 17 facilitates the soil better entry into the screening room. 2, the inner bottom of the screening chamber 2 communicates with the outside of the discharge port 20, the inner bottom of the screening chamber 2 is concave, facilitating the soil falls from the discharge port 20, which needs to be below the discharge port 20 The collection device is placed, and the screening chamber 2 is provided with a screen 19, and a portion of the first rotor 4 is located in the screening c...

Embodiment 2

[0037] Refer Figure 5-6 The present embodiment differs from the first embodiment in that the screening chamber 2 is provided with two mounting box 29, and one end of the opposite end of the two mounting tank 29 is fixedly connected to the corresponding connecting rod 28, respectively, two mounting box 29 The lower end is connected to the thermally conductive sleeve 14, and the two mounting tank 29 is opened in the two mounting chamber 30, and the two chamagnetic cavity 30 are provided with a magnetic piston 31 for up and down slide, the upper end of the two magnetic piston 31 and Both the top of the counter restroom 30 are elastically connected by the retransmission spring 32, both of which are connected through the intake pipe 33 with the outside, and the internal top of the screening chamber 2 is fixedly connected to the annular hollow plate, the annular hollow plate. The lower end is opened with a plurality of exhaust ports, and the two transverse cavities 30 are in communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com