Disulfide composite material as well as preparation method and application thereof

A composite material and sulfide technology, which is applied in the field of photocatalytic hydrogen evolution, can solve the problems of CdS easily falling off photocatalytic effect, lack of mature and perfect solutions, influence and other problems, and achieve good catalytic hydrogen production performance, high stability and regeneration. The effect of performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033]One embodiment of the present invention provides a kind of preparation method of double sulfide composite material, comprises the following steps:

[0034] (1) Mix a certain amount of nickel salt solution with a certain amount of ligand solution, carry out an oil bath reflux reaction at a certain temperature, after a certain period of reaction, cool to room temperature, centrifuge, wash and dry to obtain a nickel metal organic framework Material;

[0035] In this step, the nickel salt solution is prepared by dissolving nickel acetate in deionized water, and the ligand solution is prepared by dissolving 2,5-dihydroxyterephthalic acid in deionized water; wherein, nickel acetate and 2 , the mass ratio of 5-dihydroxyterephthalic acid is (5-10):(2-4);

[0036] The reaction temperature of the oil bath reflux reaction is 80-100°C, and the reaction time is 1-2h; the washing is at least twice with deionized water and methanol; the drying is vacuum drying, and the drying temperat...

Embodiment 1

[0047] This embodiment provides a method for preparing a double sulfide composite material, comprising the following steps:

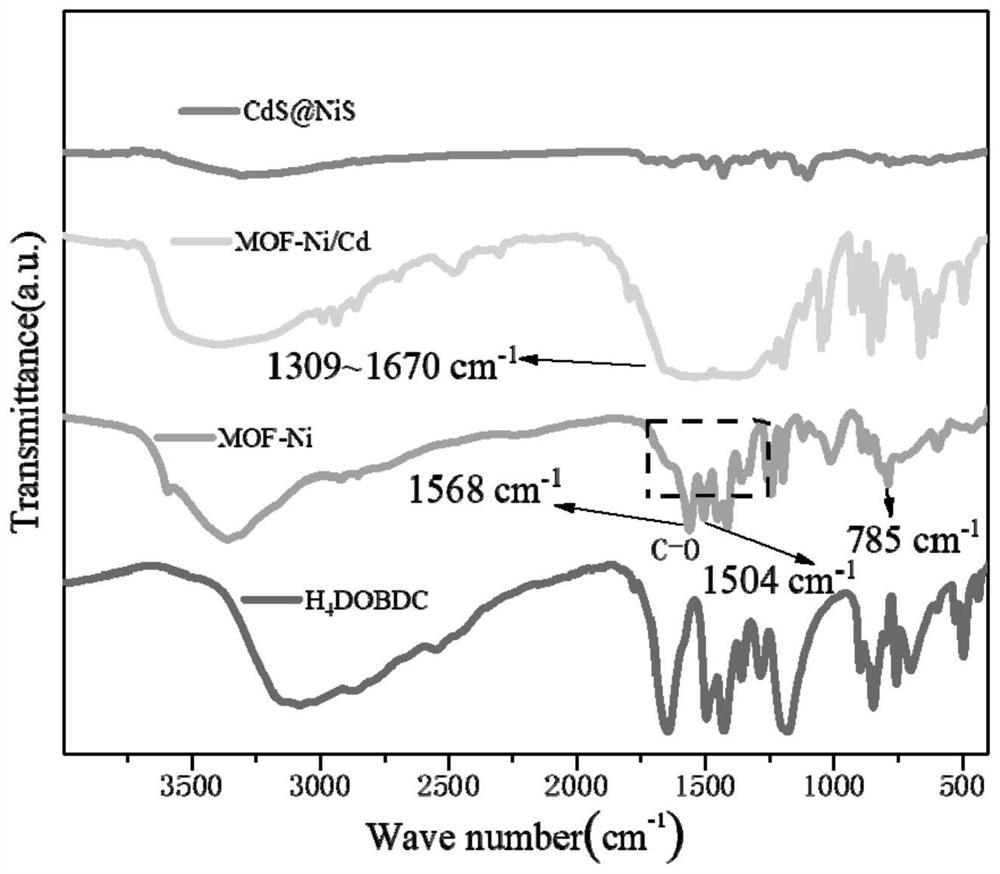

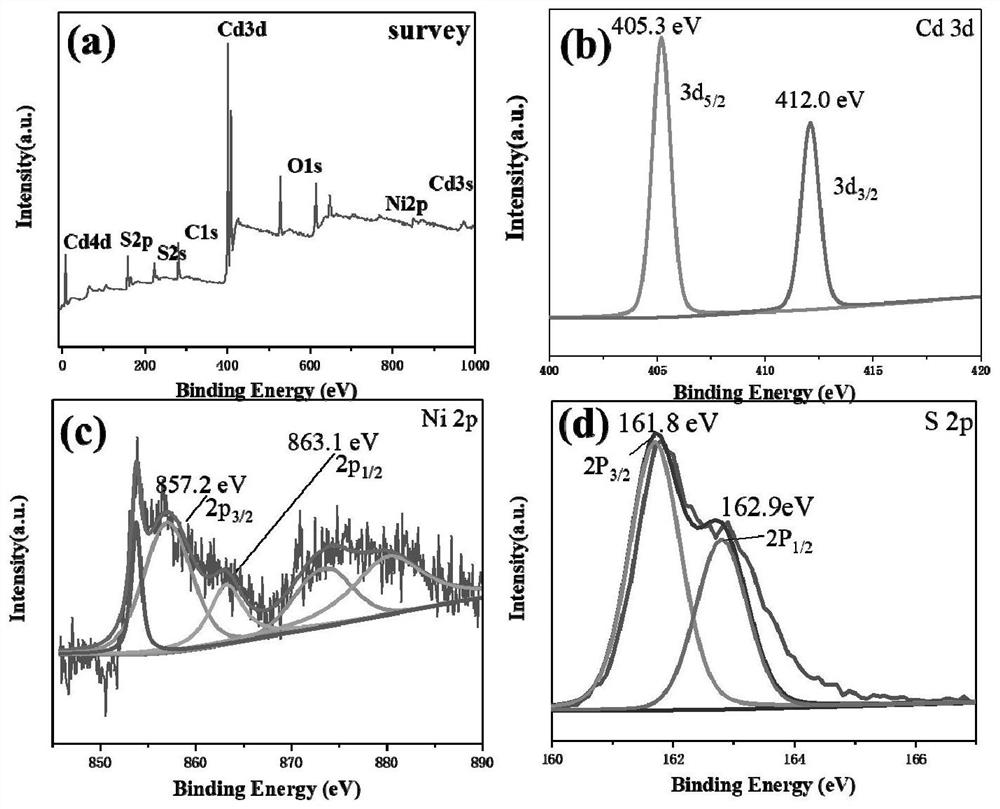

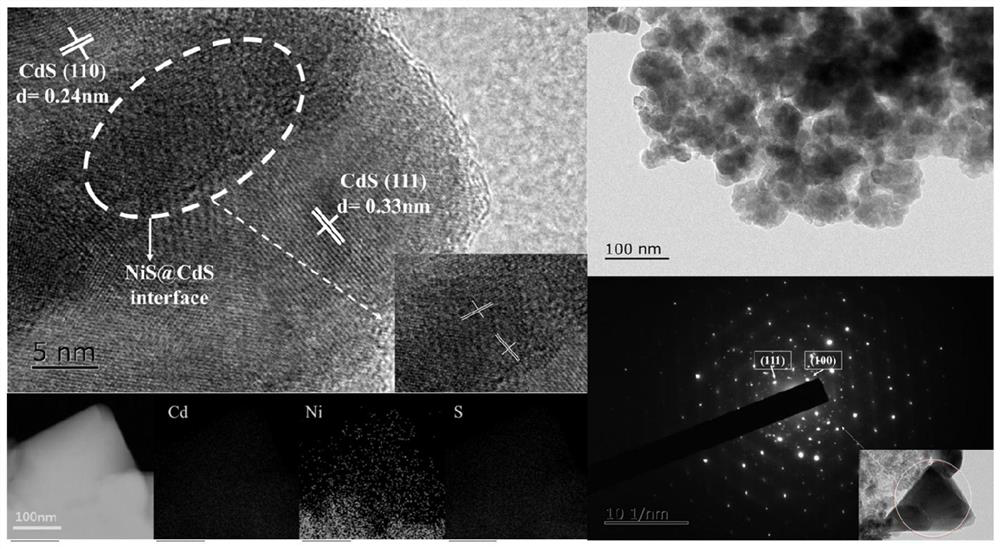

[0048] (1) Dissolve 10g of nickel acetate in 50mL of deionized water, and ultrasonically stir to obtain a uniform nickel salt solution; dissolve 4g of 2,5-dihydroxyterephthalic acid in 150mL of deionized water, and ultrasonically stir to obtain a uniform ligand solution ; Mix the prepared nickel salt solution with the ligand solution, pour it into a glass flask, carry out an oil bath reflux reaction at 100°C, stir and react for 2 hours, cool to room temperature, and centrifuge to obtain a solid precipitate. Use deionized water and methanol After washing for 3 times, vacuum drying at 80°C for 8 hours to obtain nickel metal organic framework (MOF-Ni);

[0049] (2) Dissolve 2g of cadmium acetate in 15mL of DMF, stir ultrasonically until completely dissolved, and obtain a clear cadmium salt solution; disperse 200mg of MOF-Ni obtained in step (1) in the prep...

Embodiment 2

[0053] This embodiment provides a method for preparing a double sulfide composite material, comprising the following steps:

[0054] (1) Dissolve 5g of nickel acetate in 60mL of deionized water, and ultrasonically stir to obtain a uniform nickel salt solution; dissolve 2g of 2,5-dihydroxyterephthalic acid in 120mL of deionized water, and ultrasonically stir to obtain a uniform ligand solution ; Mix the prepared nickel salt solution with the ligand solution, pour it into a glass flask, carry out an oil bath reflux reaction at 80°C, stir and react for 1 hour, cool to room temperature, and centrifuge to obtain a solid precipitate. Use deionized water and methanol After washing for 3 times, vacuum-dry at 70°C for 10 hours to obtain MOF-Ni;

[0055] (2) Dissolve 1 g of cadmium acetate in 25 mL of DMF, stir until it is completely dissolved, and obtain a clear cadmium salt solution; disperse 200 mg of MOF-Ni obtained in step (1) in the prepared cadmium salt solution, and stir for 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com