Injection needle coating material and application thereof in surface treatment of peripheral blood taking needle head

A coating material, injection needle technology, applied in coating, application, medical science and other directions, can solve problems such as unfavorable assays, and achieve the effects of alleviating pain, improving performance, and increasing lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

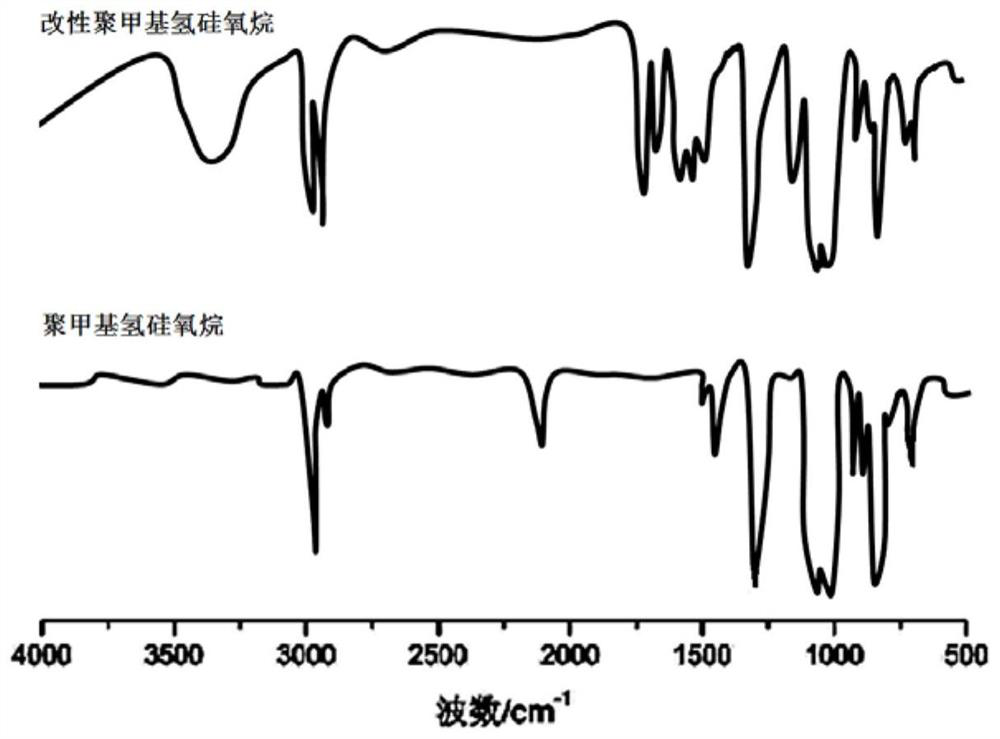

[0023] Preparation of modified silicone oil:

[0024] Dissolve caffeic acid lupeyl alcohol and polymethylhydrogensiloxane (the mass ratio of caffeic acid lupeyl alcohol and polymethylhydrogensiloxane is 4.2:1) in DMSO, and raise the temperature to 85°C under nitrogen protection. Add 5ppm of speier catalyst, react for 5h; filter while hot, cool to room temperature, spin evaporate, dry, and separate and purify by column chromatography to obtain modified silicone oil.

[0025] A raw material component of a coating solution for an injection needle coating material includes: in parts by weight, 3.5 parts of modified silicone oil, 28 parts of 4-chlorobenzotrifluoride, 25 parts of ethyl acetate, 3 parts of hydroxypropylmethyl Cellulose, 6 parts dimethylformamide.

[0026] An injection needle coating material forms a coating on the surface of the needle by impregnating the injection needle with a coating solution. The thickness of the formed coating is 15±0.7 μm.

Embodiment 2

[0028] The preparation of modified silicone oil is identical with embodiment 1;

[0029] A raw material component of a coating solution for an injection needle coating material includes: in parts by weight, 3.5 parts of modified silicone oil, 28 parts of 4-chlorobenzotrifluoride, 25 parts of ethyl acetate, 3 parts of hydroxypropylmethyl Cellulose, 6 parts dimethylformamide, 1.2 parts fucoidan sulfate.

[0030] The preparation of an injection needle coating material is the same as in Example 1, and the thickness of the formed coating is 24.5±0.3 μm.

Embodiment 3

[0032] The difference between the preparation of modified silicone oil and Example 2 is that the mass ratio of caffeic acid lupeyl alcohol and polymethylhydrogensiloxane is 3.8:1;

[0033] A raw material component of a coating solution for an injection needle coating material includes: by weight, 2 parts of modified silicone oil, 22 parts of 4-chlorotrifluorotoluene, 16 parts of ethyl acetate, 2 parts of hydroxypropylmethyl Cellulose, 5 parts of dimethylformamide, 0.9 parts of fucoidan sulfate.

[0034] The preparation of an injection needle coating material is the same as in Example 1, and the thickness of the formed coating is 14.3±0.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com