Stator structure for weakening electromagnetic exciting force of motor

A technology of electromagnetic excitation force and stator structure, applied in the direction of magnetic circuit shape/style/structure, winding insulation shape/style/structure, electromechanical devices, etc., can solve the problems of lack of suppression measures, deterioration of motor vibration and noise performance, etc. , to achieve the effect of improving the transmission path, weakening the electromagnetic excitation force, and improving vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail in conjunction with the accompanying drawings.

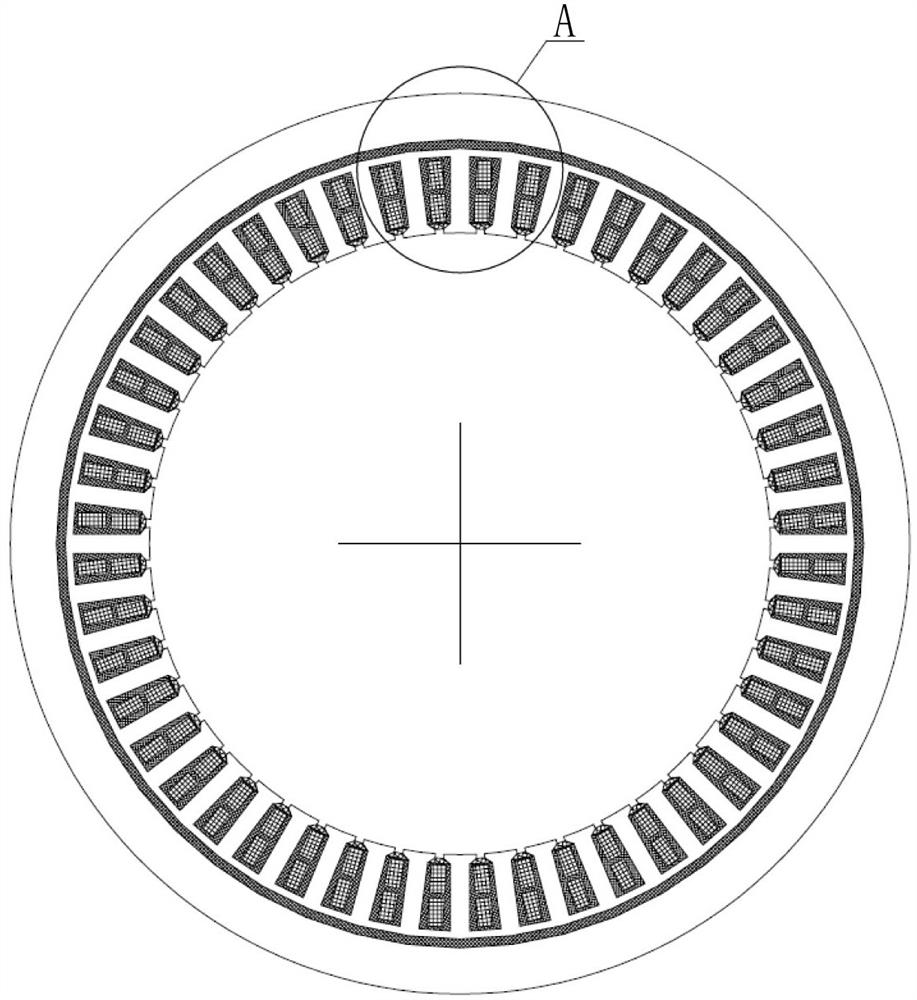

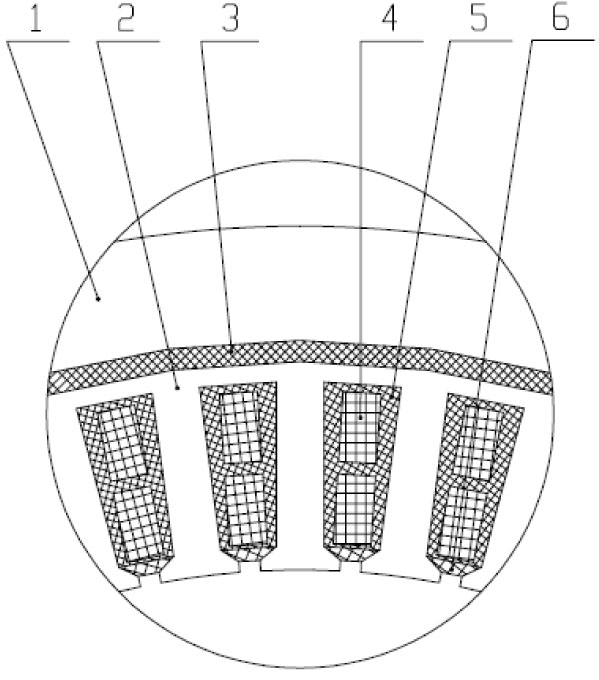

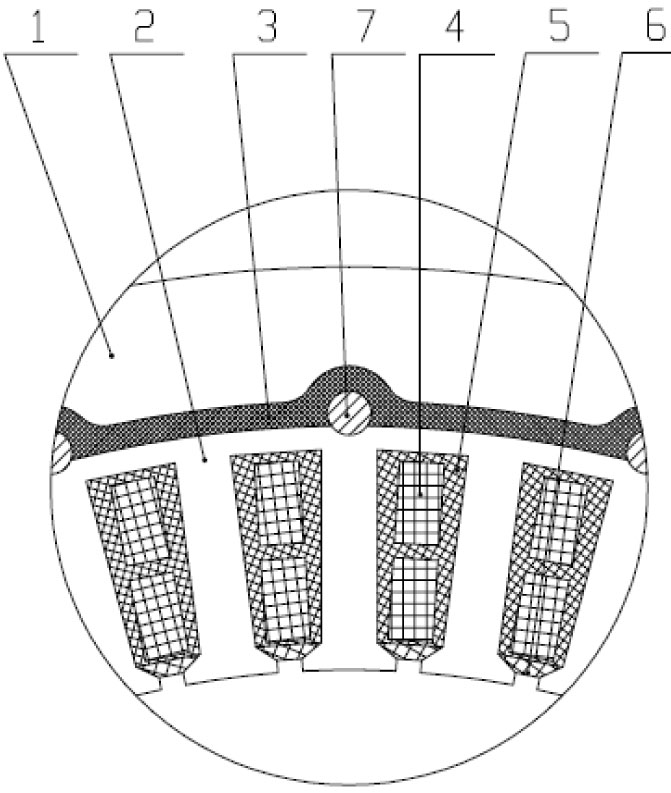

[0020] refer to figure 1 , figure 2 As shown, as the first embodiment of the present invention, for the specific example of the slot number Z=48, a stator structure for weakening the electromagnetic excitation force of the motor is proposed, including the stator yoke part 1, the stator tooth part 2, the magnetic resistance Ni layer 3, stator winding 4, insulating material 5 and slot wedge 6, stator yoke 1 and stator teeth 2 are made of laminated silicon steel sheets, separated by magnetic damping layer 3 in the middle; stator yoke 1 and stator The magnetic damping layer between teeth 2 is made of modified rubber material, which has good magnetic permeability (generally relative magnetic permeability) and damping performance. It is painted, bonded, sintered or potted on the stator Between the tooth part and the yoke part; in order to transmit torque, the mating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com