Backlight module, preparation process thereof and display device

A technology of backlight module and preparation process, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as excessive narrow frame defects, and achieve the effects of saving installation time, reducing narrow frames, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

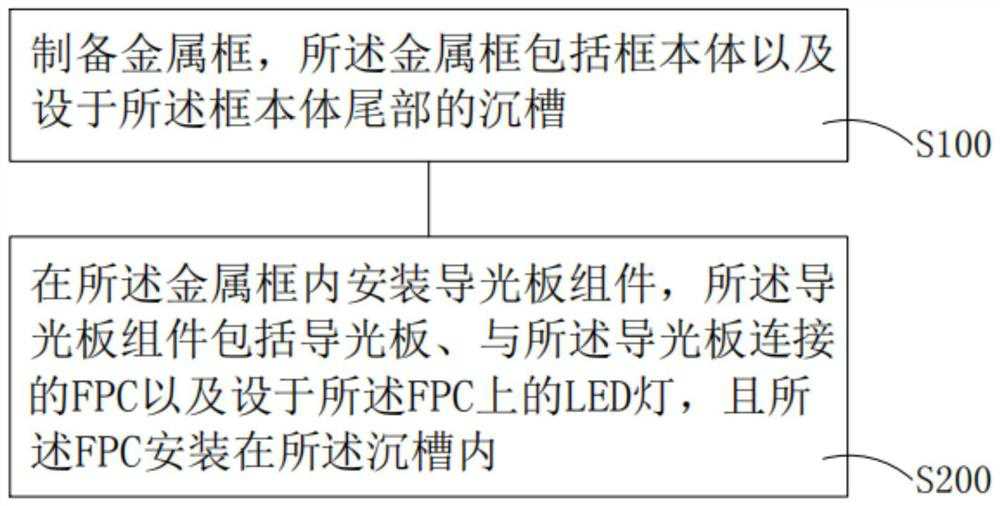

[0055] The working principle of the preparation process of the backlight module provided in this embodiment:

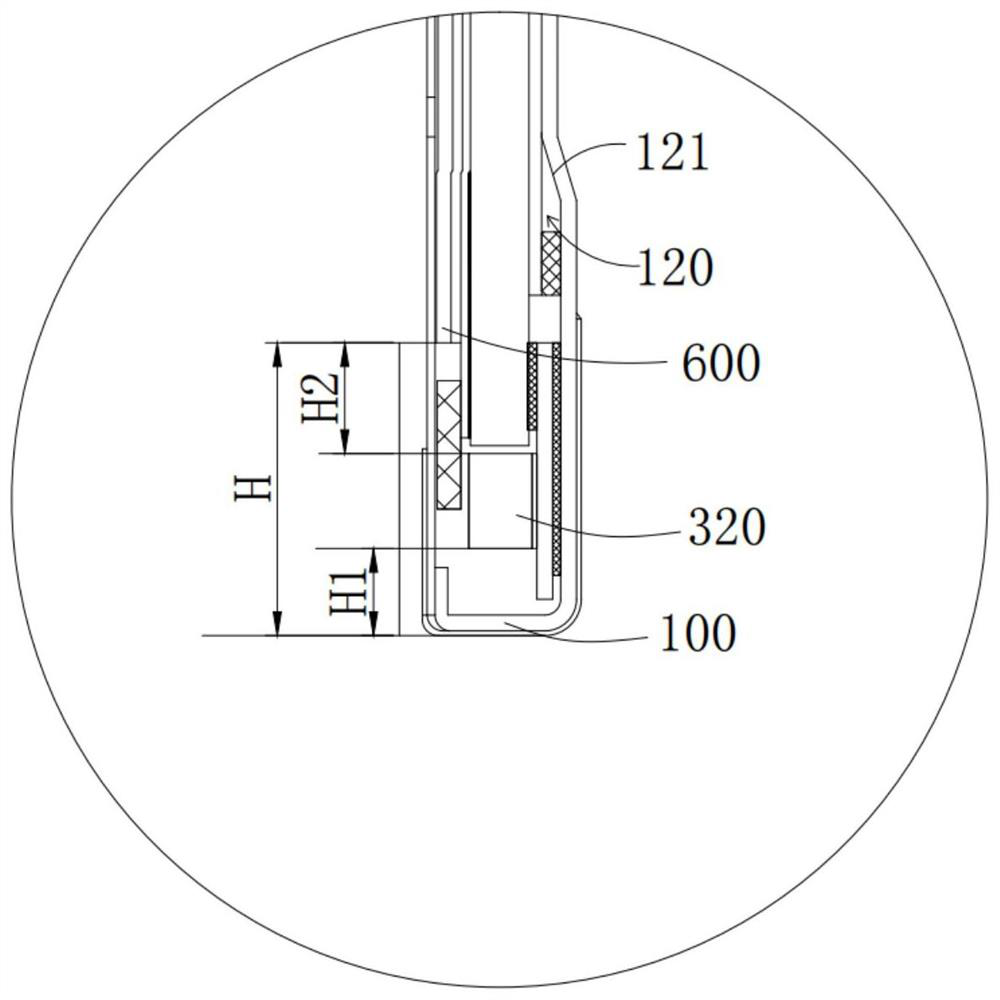

[0056] In the prior art, the FPC is installed on the plastic frame, and the plastic frame is embedded in the metal frame, wherein the metal frame, the plastic frame, the LED lamp and the light guide plate are arranged in sequence, and the FPC is located on the plastic frame, and the FPC occupies a certain width. Furthermore, the distance H2 between the LED light and the visible area is increased, and the FPC needs to bypass the LED light to connect to the motherboard, which will increase the distance H1 between the LED light and the metal frame tail frame to a certain extent, and the plastic frame is located between the LED light and the metal frame , which greatly increases the distance H1 between the LED lamp and the tail frame of the metal frame, thereby greatly increasing the distance H between the visible area and the tail frame of the metal frame.

[0057]Usuall...

Embodiment 1

[0094] S1, automatic feeding metal frame;

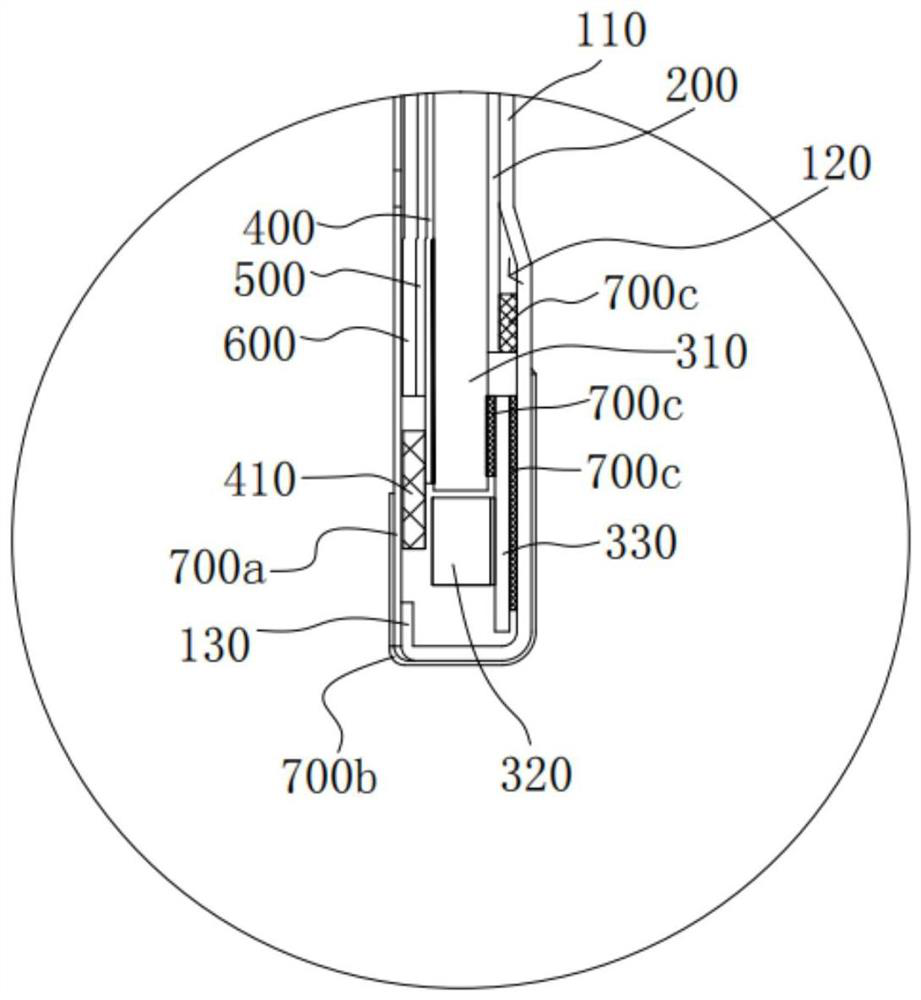

[0095] Specifically, the metal frame 100 includes a frame body 110 , a sinker 120 , and a U-shaped groove 130 . Before loading the metal frame 100 , the sinker 120 and the U-shaped groove 130 are processed on the metal frame 100 .

[0096] S2, paste reflective sheet;

[0097] S3. Insert the light guide plate assembly obliquely into the metal frame;

[0098] Specifically, the suction block sucks the light-emitting surface of the light guide plate 310, the suction block rotates 15 degrees, inserts the FPC light bar 300a obliquely into the corresponding sinker groove 120 in the metal frame 100, and then adjusts the position of the light guide plate 310 away from the FPC light bar 300a. Put it into the metal frame 100 at one end.

[0099] S4, paste diffusion film;

[0100] S5, paste the brightness enhancement film;

[0101] S6, affix the enhancement film;

[0102] S7, paste light-shielding glue;

[0103] S8, one-sided adhesive tape f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com