Cooling pipe assembly with static electricity releasing function, cooling device and plasma processing equipment

A technology for cooling devices and cooling pipes, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of hose 30 damage, interference with substrate adsorption, liquid leakage, etc., to improve safety, prevent arcs, and reduce failures The effect of the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 〉

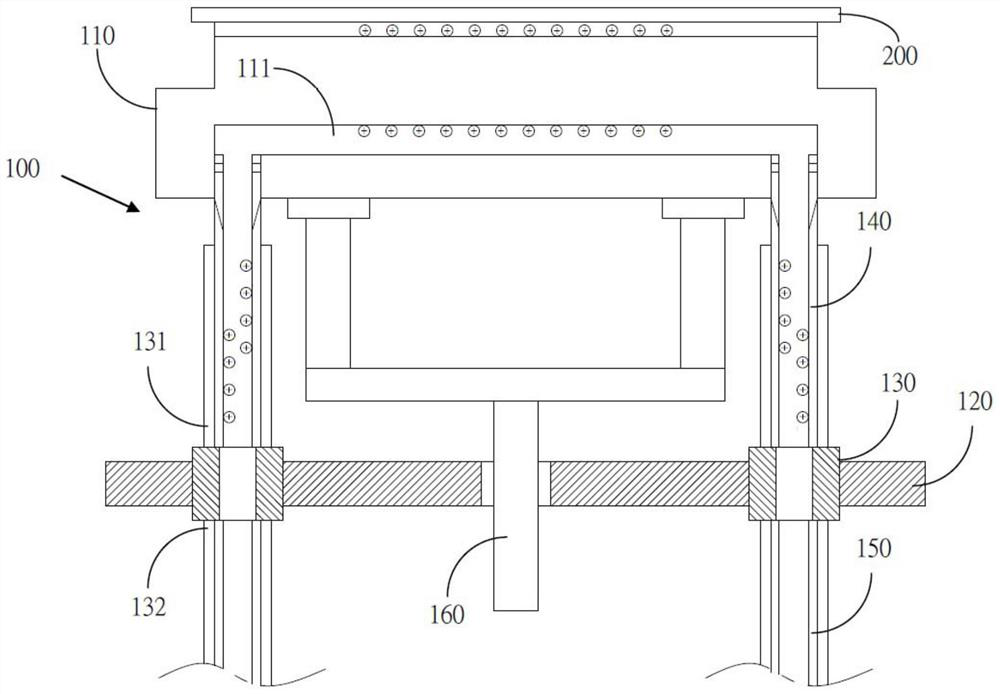

[0025] see figure 2 , which is a schematic diagram of the first embodiment of the cooling device with static discharge function of the present invention. As shown in the figure, the first embodiment of the present invention provides a cooling device 100 with the function of discharging static electricity, which includes a substrate 110, a radio frequency shielding plate 120, a cooling pipe connector 130, a high resistance cooling pipe 140 and a metal cooling pipe 150.

[0026] Furthermore, a cooling channel 111 is disposed in the substrate 110 , and an electrostatic chuck (ESC) 200 is connected above the substrate 110 . The radio frequency shielding plate 120 is disposed under the substrate 110 . The cooling pipe connector 130 is disposed in the radio frequency shielding plate 120 , and has a first end 131 and a second end 132 of the cooling pipe connector 130 on the upper surface and the lower surface of the radio frequency shielding plate 120 respectively. One end of the...

no. 2 example

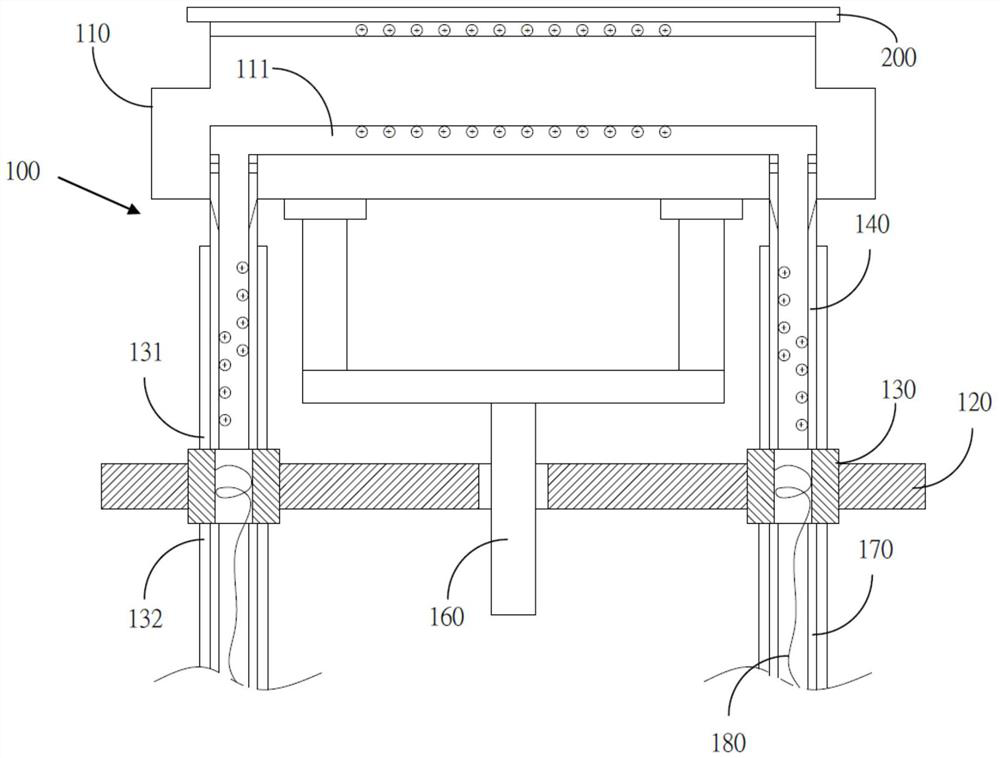

[0037] see image 3 , which is a schematic diagram of the second embodiment of the cooling device with static discharge function of the present invention. As shown in the figure, the second embodiment of the present invention is to provide in order to achieve the above purpose, the second technical solution of the present invention is to provide a cooling device 100 with the function of discharging static electricity, the substrate 110, the radio frequency shielding plate 120, and the cooling pipe are connected Device 130, high resistance cooling pipe 140 and non-metallic cooling pipe 160

[0038] Furthermore, a cooling channel 111 is disposed in the substrate 110 , and the electrostatic chuck 200 is connected above the substrate 110 . The radio frequency shielding plate 120 is disposed under the substrate 110 . The cooling pipe connector 130 is disposed in the radio frequency shielding plate 120 , and has a first end 131 and a second end 132 of the cooling pipe connector 130 ...

no. 3 example 〉

[0049] see Figure 4 , which is a schematic diagram of the third embodiment of the cooling device with static discharge function of the present invention. As shown in the figure, the third embodiment of the present invention is to provide in order to achieve the above purpose, the third technical solution of the present invention is to provide a cooling device 100 with the function of discharging static electricity, which includes a substrate 110, a radio frequency shielding plate 120, a cooling The tube connector 130 , the high-resistance cooling tube 140 and the cooling tube 190 . The substrate 110 is provided with a cooling channel 111 , and the upper part of the substrate 110 is connected to the electrostatic chuck 200 . The radio frequency shielding plate 120 is disposed under the substrate 110 . The cooling pipe connector 130 is disposed in the radio frequency shielding plate 120 , and has a first end 131 and a second end 132 of the cooling pipe connector 130 on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com