Exhaust gas discharge nozzle

A nozzle and exhaust flow path technology, applied in the field of exhaust outlet nozzles, can solve problems such as inability to monitor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

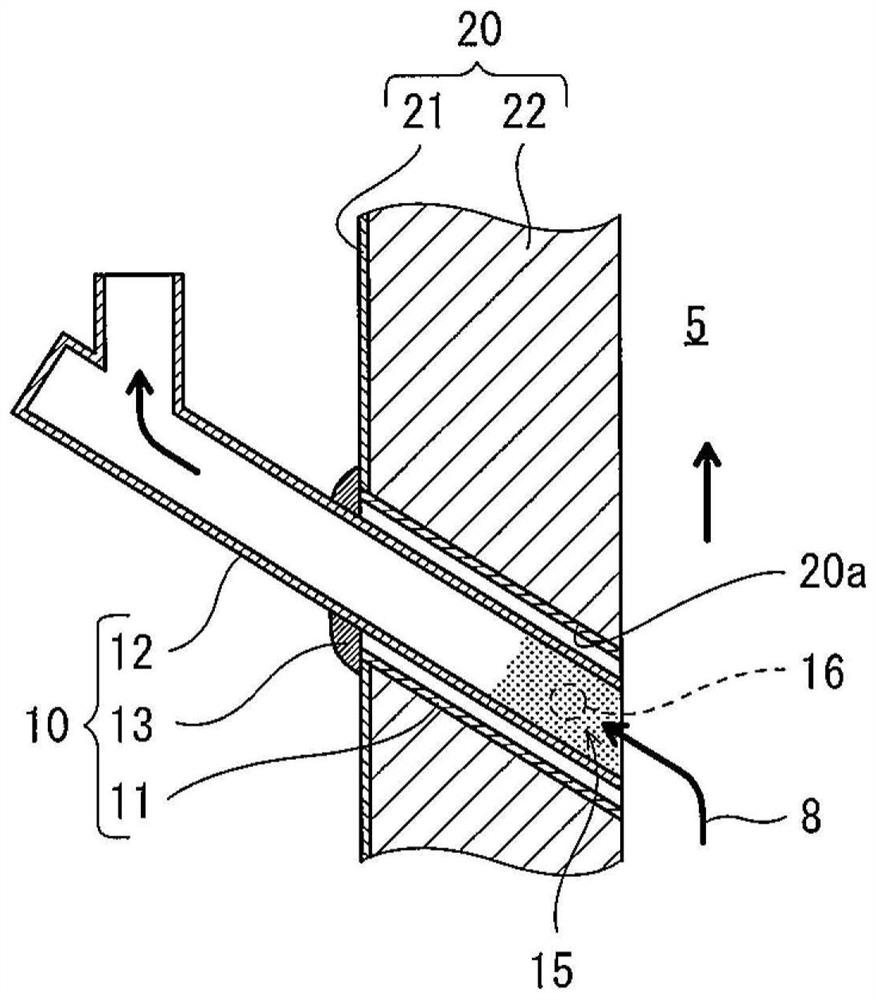

[0037]

[0038] First, the exhaust flow path provided with the exhaust outlet nozzle according to Embodiment 1 will be described. The exhaust flow path is not particularly limited as long as it is a flow path through which high-temperature exhaust gas that generates corrosive liquid flows when the temperature is not higher than the acid dew point. As such an exhaust gas flow path, an exhaust gas flow path of waste incineration facilities, biomass fuel combustion facilities, or by-products of chemical plants is exemplified. Hereinafter, the exhaust gas outlet nozzle will be described by taking the exhaust flow path of a waste incinerator as an example. The use of the exhaust gas extracted by the exhaust gas extraction nozzle is not particularly limited.

[0039]

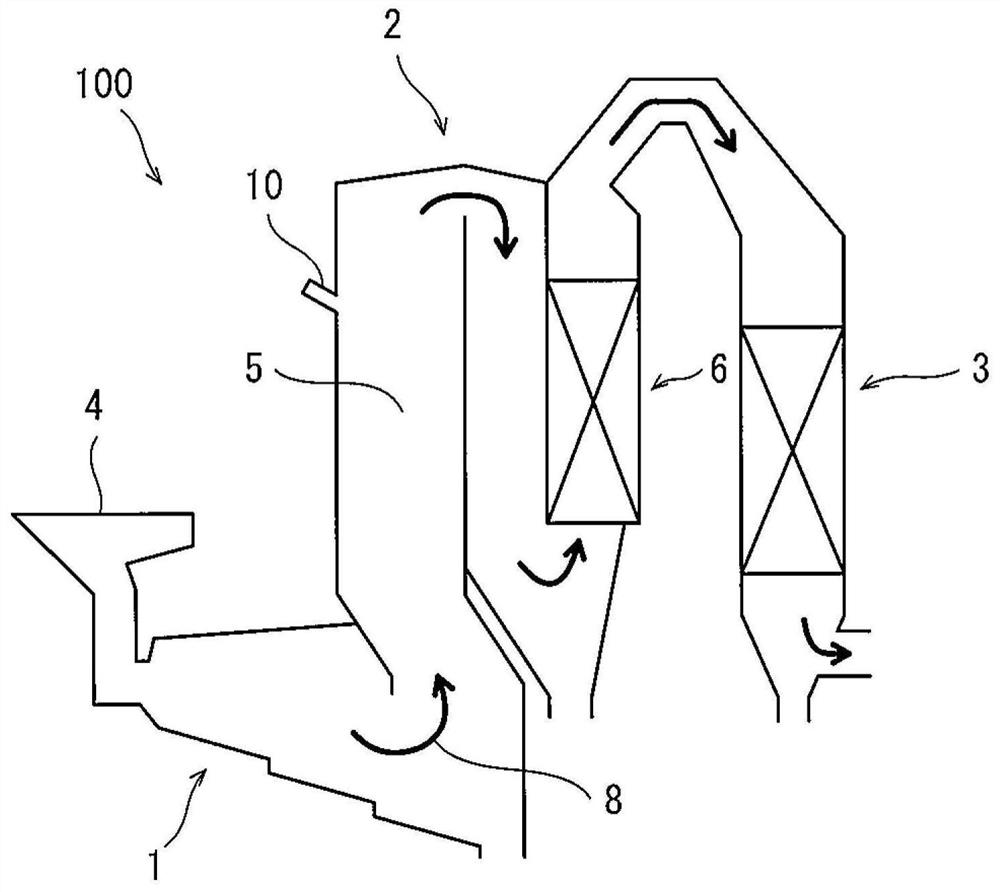

[0040] figure 1 It is a schematic diagram showing the outline of a waste incineration facility provided with the exhaust gas outlet nozzle according to the first embodiment.

[0041] refer to figure 1 , the ...

Embodiment approach 2

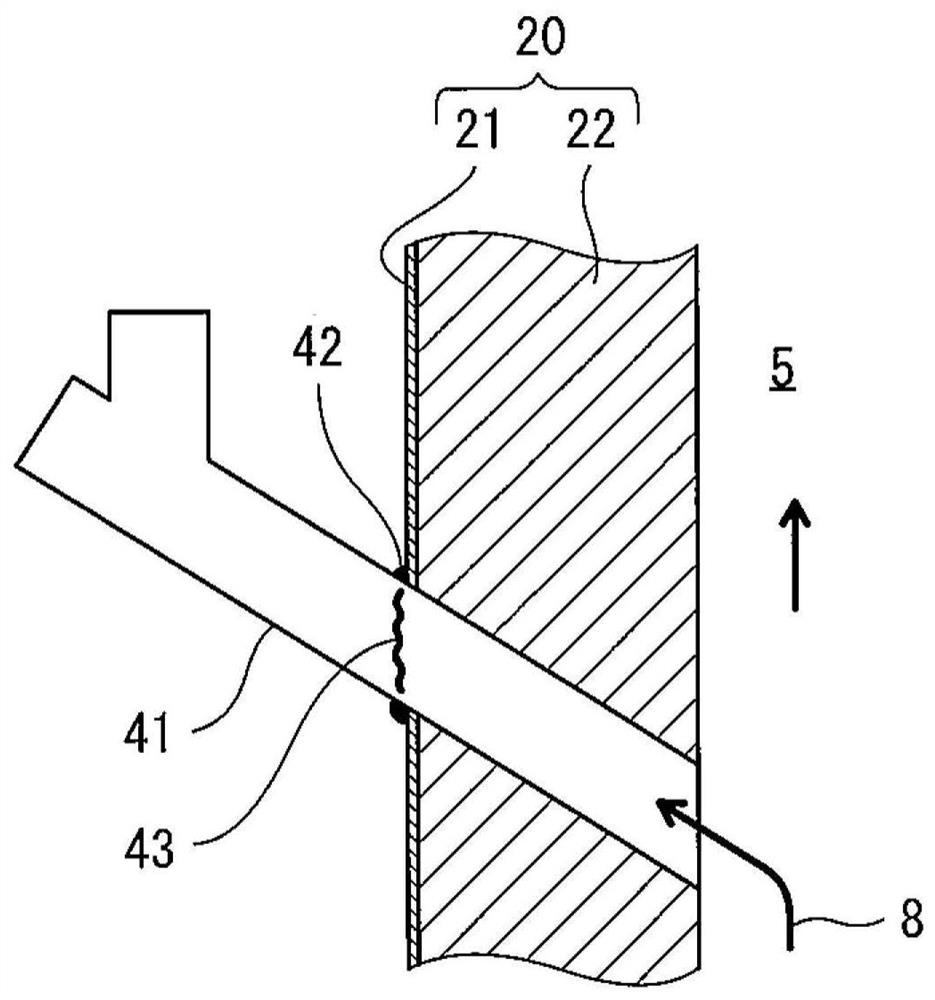

[0059] Figure 4 It is a cross-sectional view showing the configuration of the exhaust gas outlet nozzle according to the second embodiment.

[0060] refer to Figure 4 , in the exhaust outlet nozzle 10 according to Embodiment 2, the inner cylinder 12 is divided into a first portion 12A including the non-corrosion portion 15 and a second portion 12B which is a remaining portion after removing the first portion 12A from the inner cylinder 12 . The base end (lower end) of the second part 12B is in contact with the front end (upper end) of the first part 12A. The portion of the second portion 12B protruding from the outer cylinder 11 is detachably fixed to, for example, the casing 21 of the wall 20 by an appropriate fixing means that does not generate tensile stress. Other configurations are the same as those of the exhaust outlet nozzle 10 according to the first embodiment.

[0061] According to such Embodiment 2, when the thickness of the 2nd part 12B is thinned by the flowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com