Linear friction welding joint uniaxial tension simulation calculation method

A linear friction welding and uniaxial stretching technology, applied in design optimization/simulation, CAD numerical modeling, sustainable transportation, etc., can solve problems such as superalloy joints that are not involved, and ensure predictability and continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

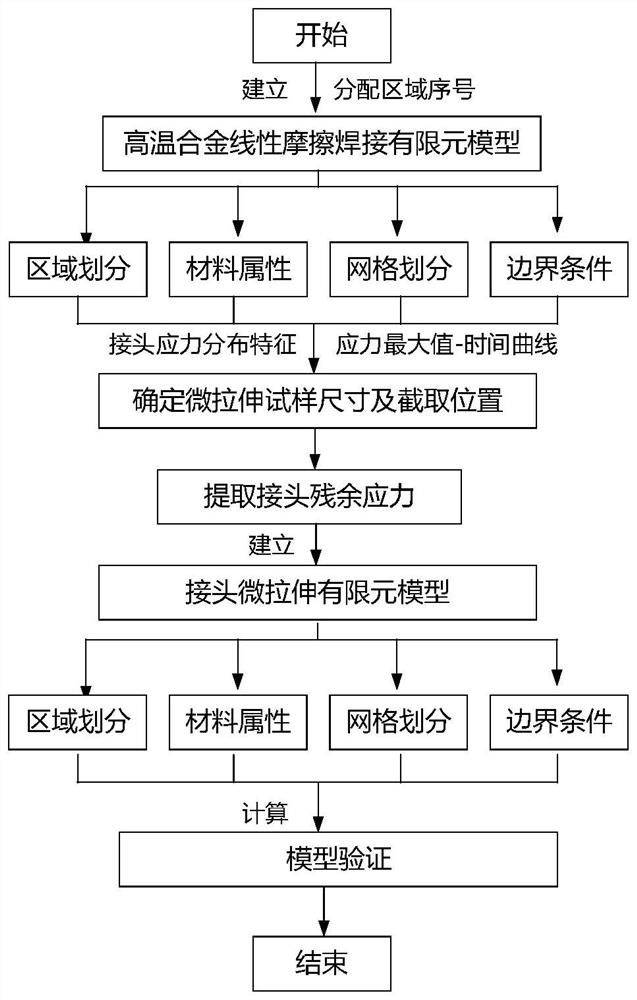

[0085] The specific method of this embodiment includes the following steps:

[0086] (1) Stress data collection steps at the sampling position of the post-weld stress nephogram:

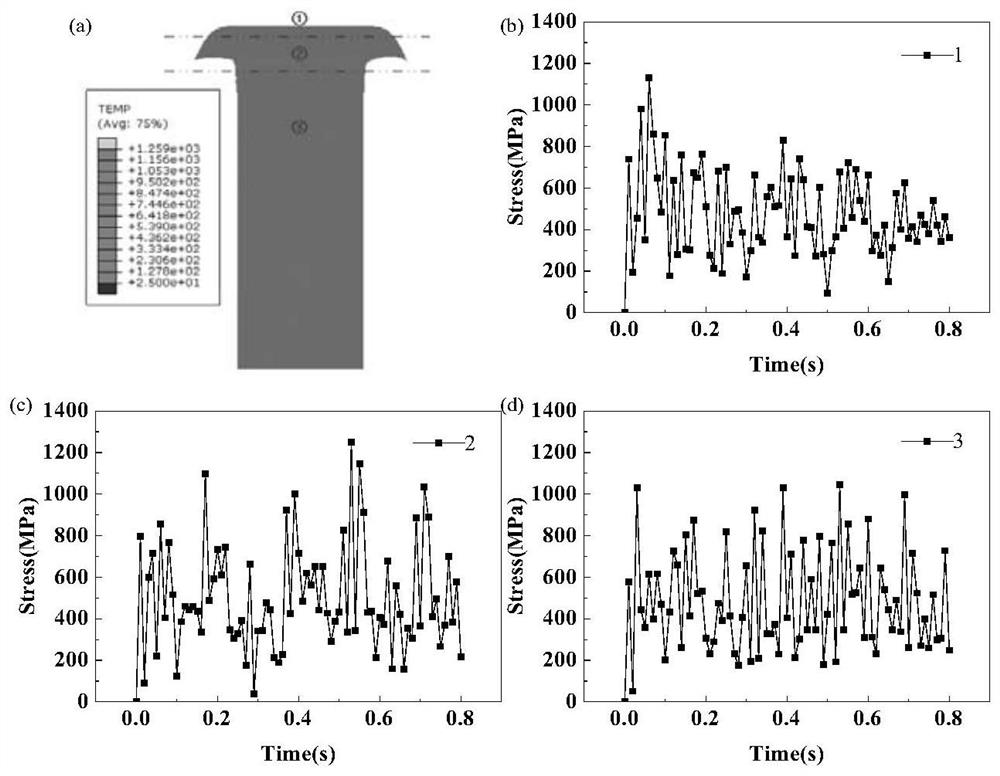

[0087] The steps are based on the post-processing analysis of the superalloy linear welding stress nephogram, respectively collecting the stress data S11, S22, S33 and S12 at five positions selected in the joint, and the sampling positions of the micro-tensile specimens are shown in Figure 4, BRIEF DESCRIPTION OF THE DRAWINGS 5 is a graph of stress data at five sampling locations.

[0088] (2) Steps for establishing a micro-stretch geometric model:

[0089] The part module in ABAQUS is used to establish the micro-tensile geometric model. According to the different sampling positions, the heat-affected zone of the weld zone and the base metal area of the micro-tensile geometric model are divided, and the 5 sampling points are respectively located in the center of the micro-tensile sample. . The t...

Embodiment 2

[0100] (1) Steps for establishing a micro-stretch geometric model:

[0101] The same as the geometric model modeling steps of Node 1 in Embodiment 1.

[0102] (2) Define the mechanical parameters, thermodynamic parameters and GTN damage constitutive parameters of the micro-tensile specimen of the linear welded joint. Steps:

[0103] Same as the material property setting of Node 1 in Example 1.

[0104] (3) Boundary conditions and predefined field setting steps:

[0105] It is the same as the prestress application steps of node 1 in embodiment 1. In this step, the predefined temperatures of the micro-tensile specimens are set as 293°C, 400°C and 650°C respectively, and there are three finite element models in total.

[0106] (4) Grid attributes and control steps:

[0107] Same as the grid attributes and control steps of node 1 in Embodiment 1.

[0108] (5) Calculation and post-processing analysis steps:

[0109] Post-processing analysis obtained the micro-tensile fracture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com