Solid-liquid switching valve

A technology for switching valves and valve bodies, applied to multi-way valves, valve devices, valve details, etc., can solve time-consuming and labor-intensive problems, and achieve reliable, stable, continuous and stable discharge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

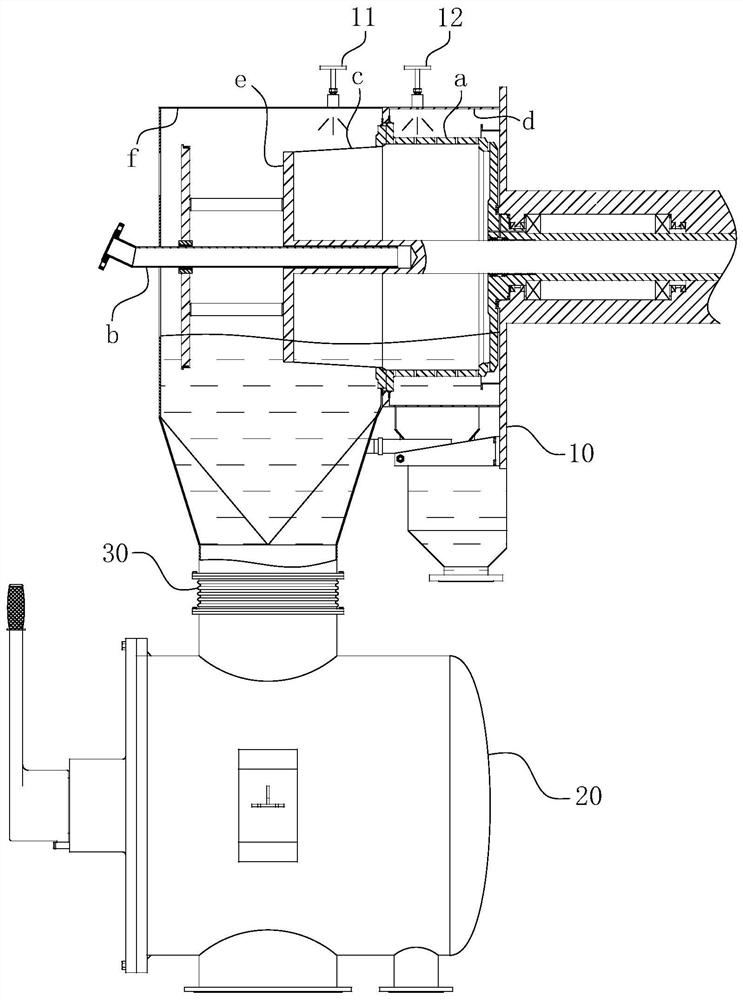

[0042] For ease of understanding, the specific structure and working method of the present invention are further described as follows:

[0043] The working process of the traditional inverted bag type centrifuge 10 is as follows:

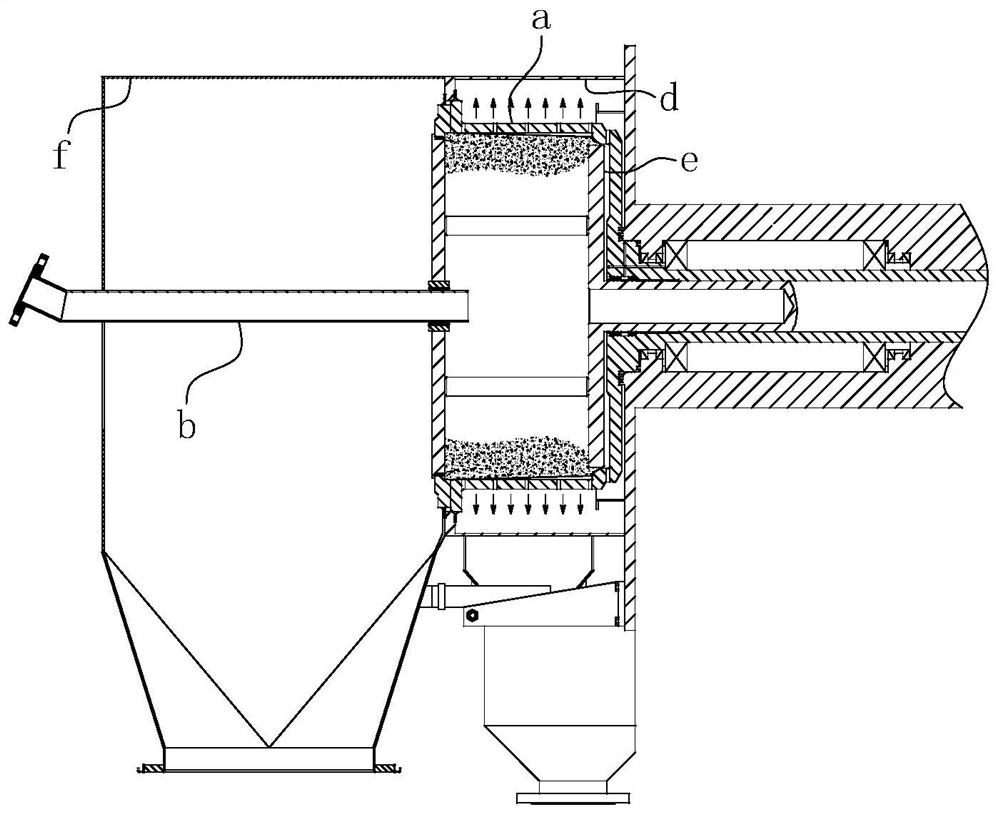

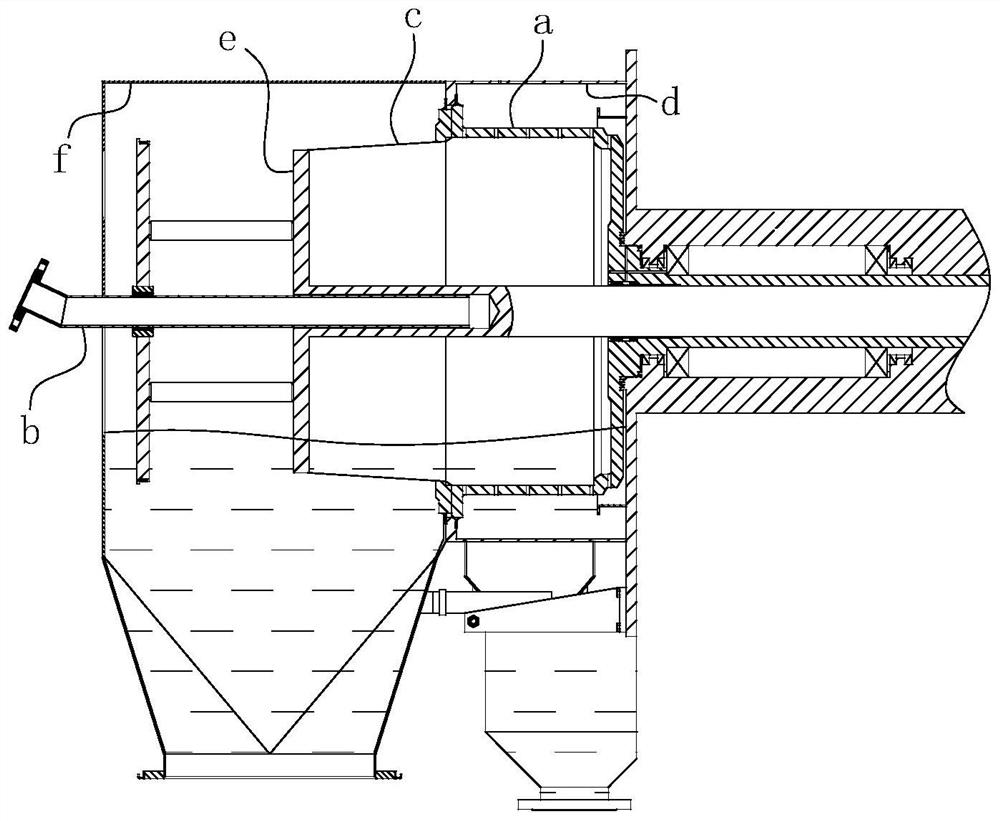

[0044] like figure 1 As shown, the suspension enters the drum a located in the mother liquor chamber d from the feed pipe b of the inverted bag centrifuge 10 . A filter cloth c is arranged coaxially on the inner surface of the drum a, and the filter cloth c is in the shape of a cylinder with openings at both ends. Select according to the particle size distribution of the material. After the suspension enters the drum a, under the action of centrifugal force, the solid is retained by the filter cloth c, and the mother liquor passes through the filter cloth c and a series of small holes on the drum a, is thrown into the mother liquor chamber d, and finally passes through The mother liquor is exported and discharged out of the machine. The intercep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com