Full-automatic waterproof roll laying device of waterproof board trolley and laying method thereof

A technology of waterproofing membrane and laying device, which is applied in mining equipment, shaft equipment, earthwork drilling, etc., can solve the problems of easy occupation of construction passages, long construction period, low construction, etc., so as to achieve no occupation of construction passages, laying and hanging engineering volume, etc. Small size and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

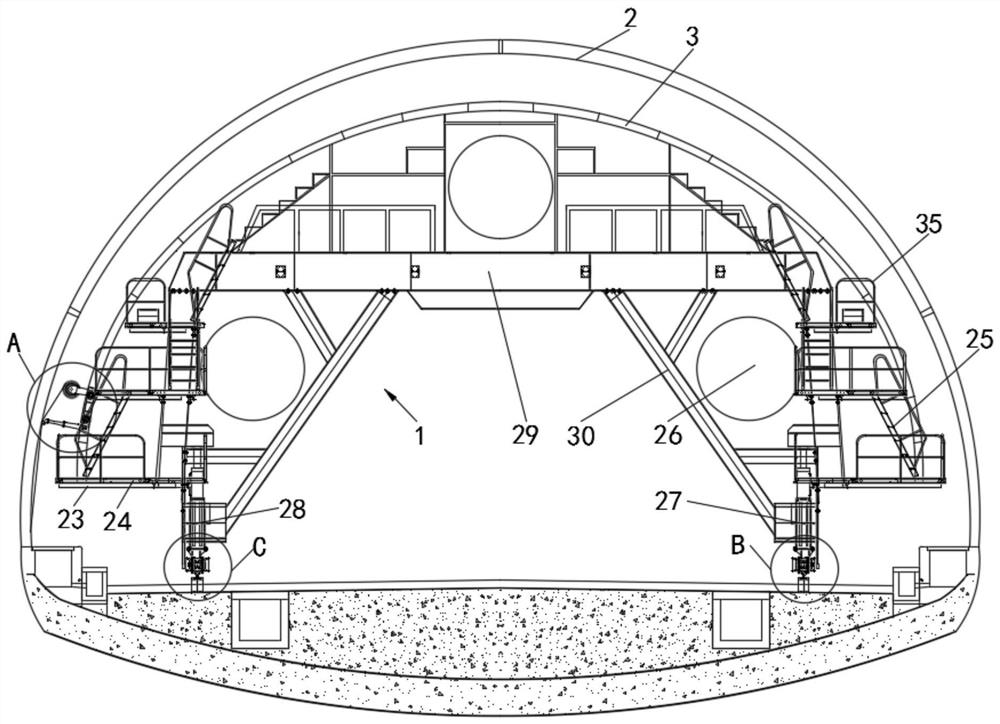

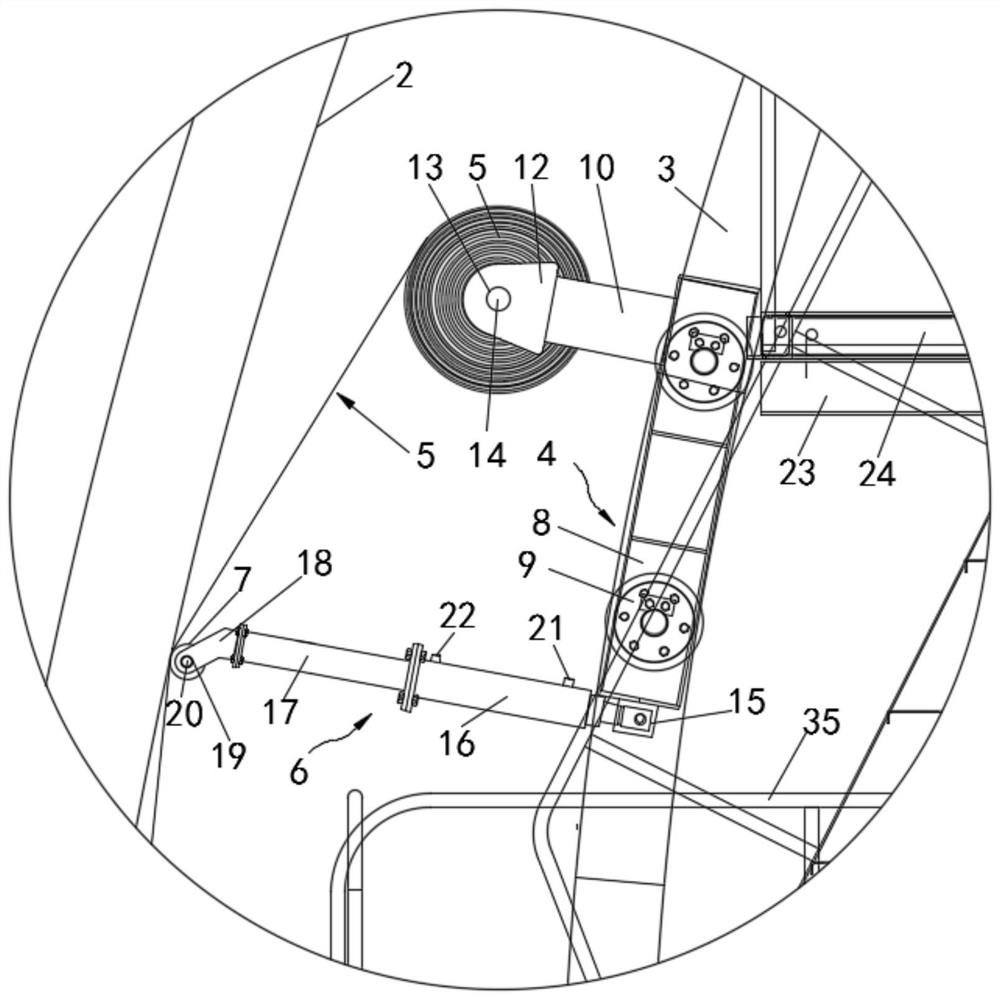

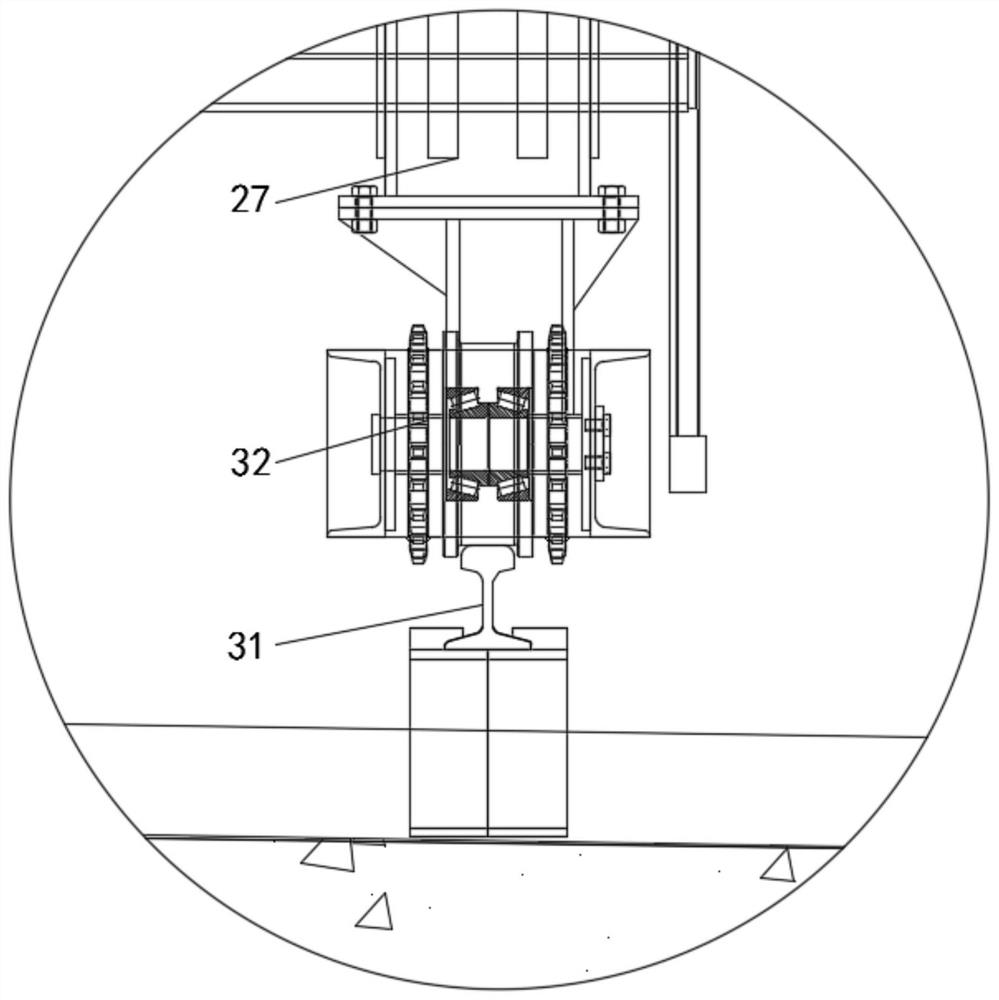

[0041] see figure 1 and figure 2, the present embodiment proposes a waterproof board trolley automatic waterproof coil laying device, including a platform 1 and a tunnel initial support surface 2; an arc-shaped Slide rail 3, the two ends of above-mentioned slide rail 3 are respectively fixedly connected to the both sides of above-mentioned platform 1, and the radian of above-mentioned slide rail 3 corresponds to the radian of above-mentioned tunnel primary supporting surface 2; One end of above-mentioned slide rail 3 is provided with walking Device 4, the above-mentioned running device 4 is slidably adapted to the above-mentioned slide rail 3, one end of the above-mentioned running device 4 is provided with a waterproof coiled material 5, and the above-mentioned waterproof coiled material 5 is rotatably connected to one end of the above-mentioned running device 4, and the above-mentioned walking device The other end of device 4 is provided with telescopic device 6, and one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com