Projection cloth and preparation method thereof

A technology of projection cloth and cloth base, which is applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve the problems of high production cost, complex structure, easy bending and shrinkage deformation, etc., and achieve a high degree of mechanical automation, Simple processing method and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

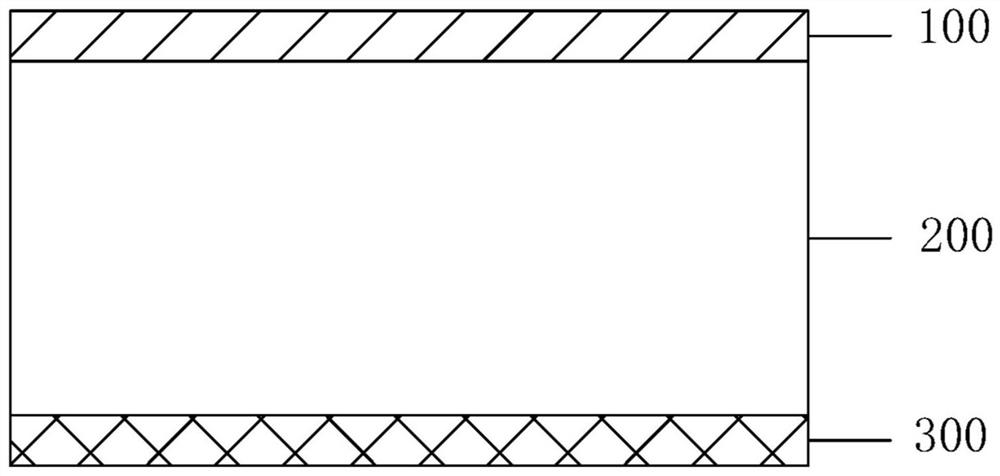

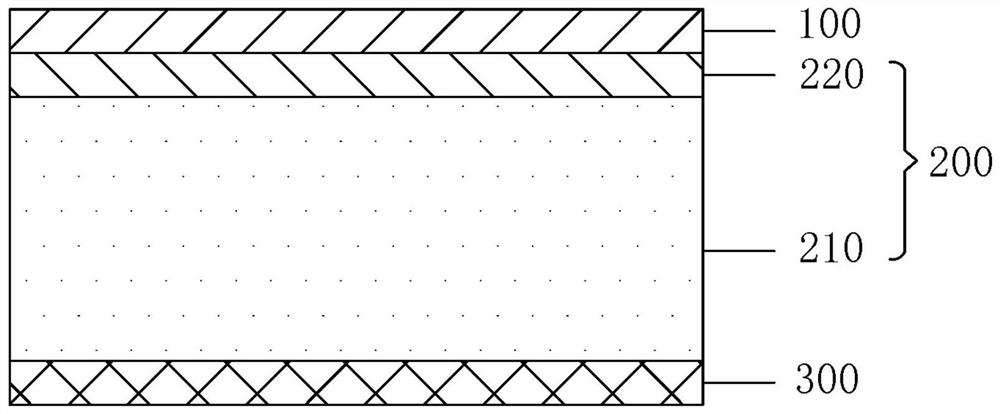

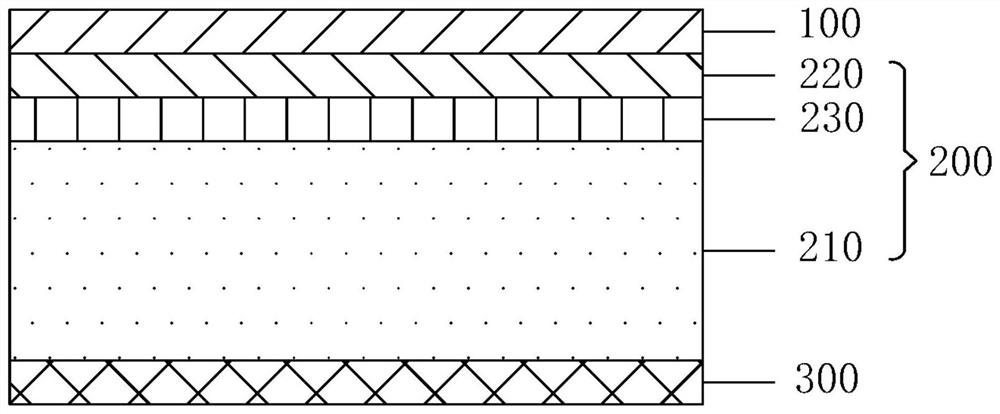

[0099] Refer to the structural composition of the projection cloth in this example image 3 .

[0100] The matte erasing layer is a matte UV coating, which is made of the following raw materials in parts by mass: 20 parts of polyurethane acrylate (8 parts of Sartomer CN929, 12 parts of Changxing 6145-100), 10 parts of epoxy acrylate ( Sartomer CN104), 10 parts of polyester acrylate (Changxing 6312-100), 5 parts of hyperbranched acrylate (Changxing 6363), 30 parts of acrylate monomer (including 6 parts of HDDA, 14 parts of TPGDA, 10 parts of TMPTA ), 8 parts of matting powder, 5 parts of wear-resistant agent (aluminum oxide), 5 parts of photoinitiator (including 4 parts of photoinitiator 184, 1 part of photoinitiator 1173), 5.5 parts of solvent (ethyl acetate), dispersant 0.5 parts (polycarboxylate), 1 part of leveling agent (DEGO300). The cloth substrate is made of 150D×150D chemical fiber cloth, which is treated with a primer layer and a surface treatment layer, and is prep...

Embodiment 2

[0108] Refer to the structural composition of the projection cloth in this example image 3 .

[0109] The matte erasing layer is matte UV coating, and it is made of the raw material of following mass parts: 30 parts of polyurethane acrylates (wherein 20 parts of Sartomer CN929, 10 parts of Changxing 6145-100), 5 parts of epoxy acrylates ( Changxing 621A-80), 5 parts of polyester acrylate (Sartomer CN293), 5 parts of hyperbranched acrylate (Changxing 6363), 25 parts of acrylate monomer (including 5 parts of NPGDA, 15 parts of TPGDA, 5 parts of TMPTA ), 8 parts of matting powder, 5 parts of wear-resistant agent (silicon carbide), 6 parts of photoinitiator (4 parts of photoinitiator 184, 1 part of photoinitiator 1173, 1 part of photoinitiator TPO), 9 parts of solvent ( Butyl acetate), 0.5 parts of dispersant (polyacrylate), 1.5 parts of leveling agent (BYK354). The cloth substrate is made of 300D×300D chemical fiber cloth through the primer layer and the surface treatment laye...

Embodiment 3

[0117] Refer to the structural composition of the projection cloth in this example image 3 .

[0118] The matte erasing layer is a matte UV coating, which is made of the following raw materials in parts by mass: 20 parts of polyurethane acrylate (Changxing 6145-100), 10 parts of polyester acrylate (Changxing 6312-100), hyperbranched acrylate 5 parts (Changxing 6363), 40 parts of acrylate monomer (10 parts of HDDA, 5 parts of DTMPTA, 25 parts of TPGDA), 8 parts of matting powder, 5 parts of wear-resistant agent (silicon dioxide), 6 parts of photoinitiator (4 parts of photoinitiator 184, 1 part of photoinitiator 1173, 1 part of photoinitiator TPO), 4 parts of solvent (xylene), 0.5 parts of dispersant (polysiloxane copolymer), 1.5 parts of leveling agent (MODAFLOW9200). The cloth substrate is made of 600D×300D chemical fiber cloth through the primer layer and the surface treatment layer, which is prepared before applying matte UV paint.

[0119] The preparation method of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com