Vacuum consumable electric arc furnace melting station safety device

A technology of vacuum consumable arc and safety device, applied in furnace safety devices, furnaces, furnace components, etc., can solve problems such as poor reliability and instability of safety devices, and achieve the ability to prevent accidental lowering, reliable extension and retraction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

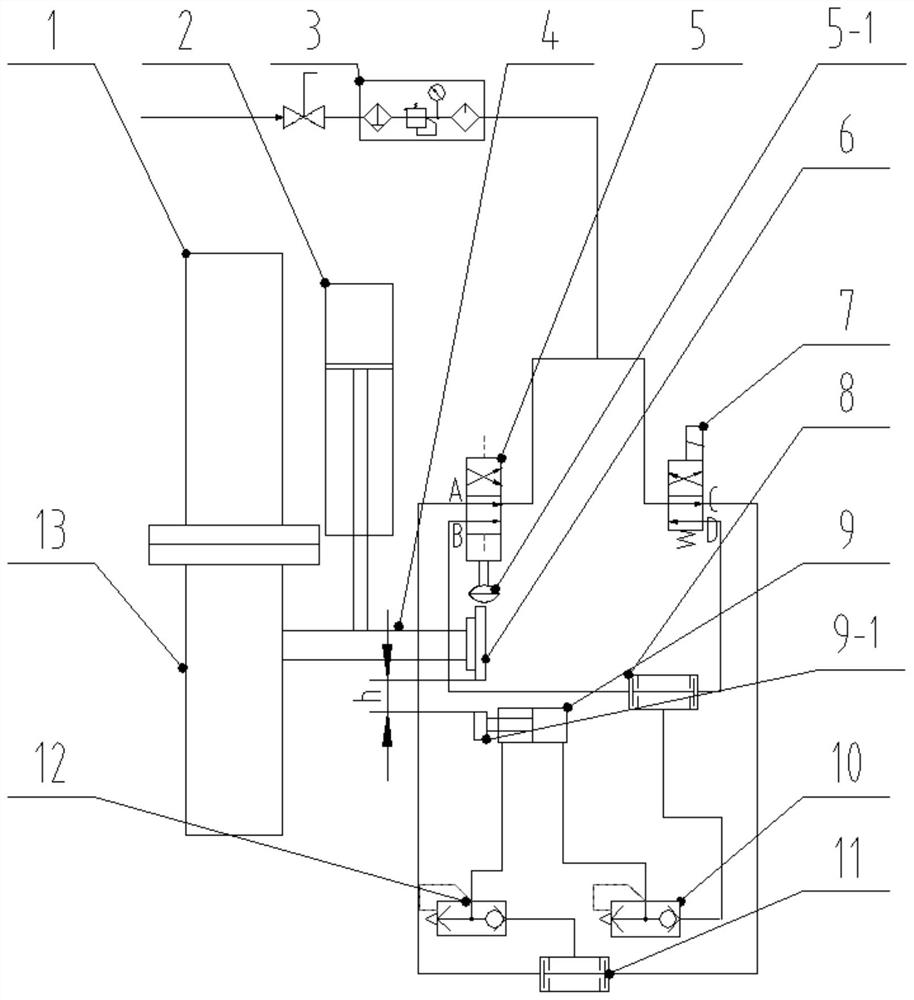

[0019] The structure and working principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] see figure 1 , a melting station safety device for a vacuum consumable electric arc furnace, comprising a fixed (fixed on the ground by a bracket) vacuum furnace chamber 1 and a melting station 13 arranged at the lower end of the vacuum furnace chamber 1, the side wall of the melting station 13 is connected with A crossbar 4, a double-acting cylinder 2 is fixed on the upper surface of the crossbar 4 (the melting station can move up or down under the drive of the crossbar through the double-acting cylinder), and the upper part of the double-acting cylinder 2 is fixed;

[0021] A guide rail seat 6 is provided at the end of the cross bar 4, and the guide rail seat 6 is provided with a matching guide rail groove, so that the cross bar runs more smoothly up and down, and the contact with the pressure head of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com