Preloading device and its control method

A control method and pre-pressing technology, which is applied to veneer presses, manufacturing tools, plywood presses, etc., can solve problems that are easy to cause work-related injuries, and achieve the effect of improving safety and avoiding accidental drops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

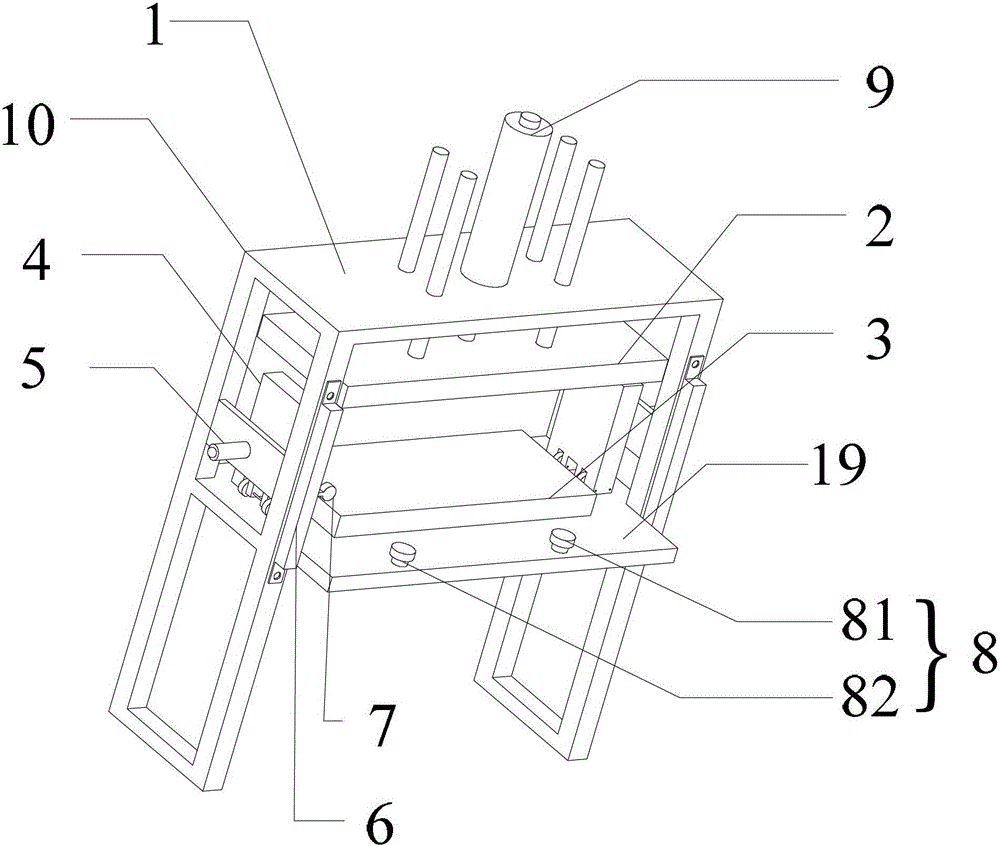

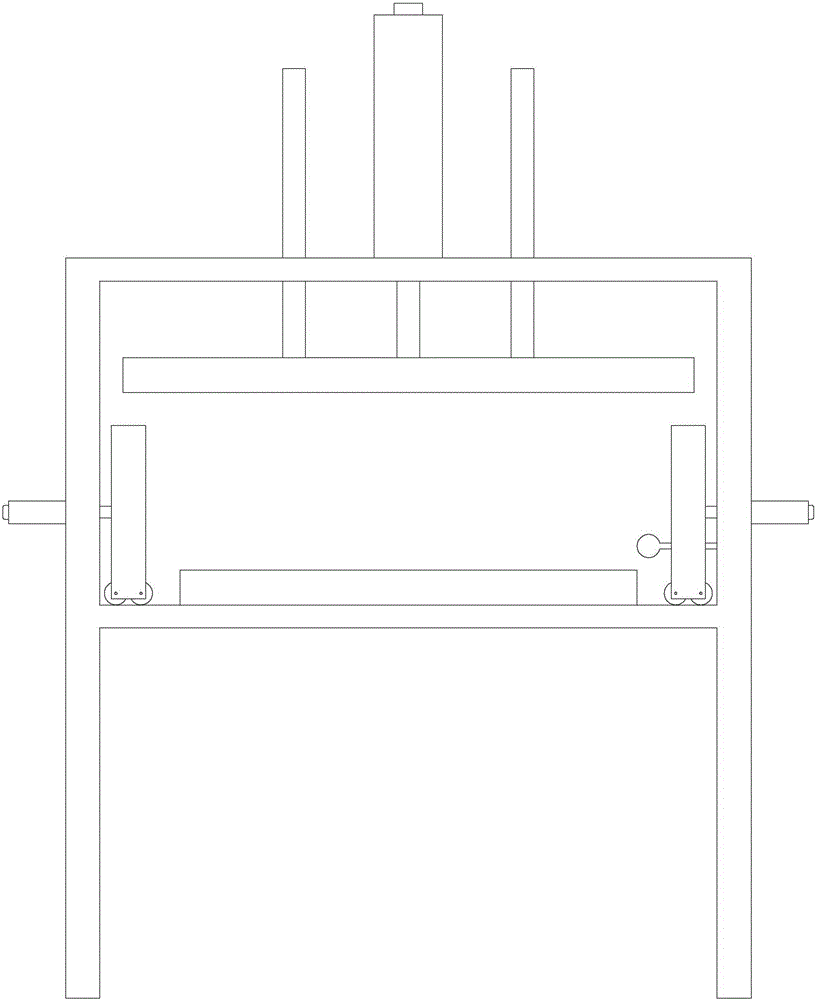

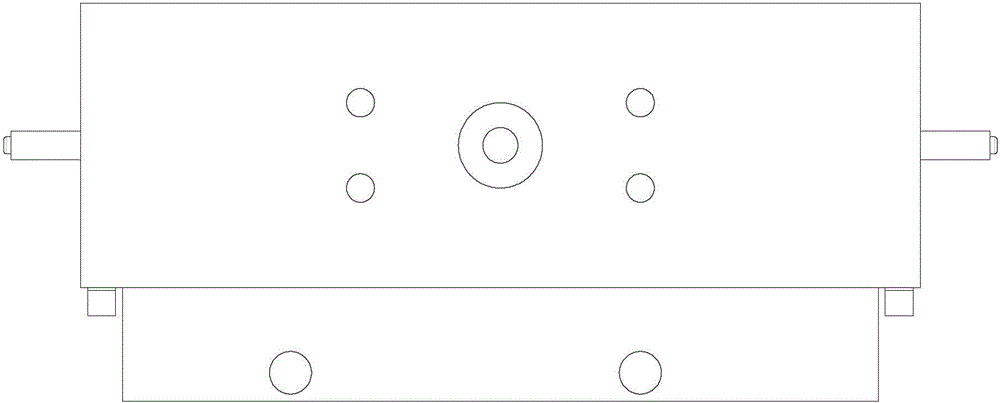

[0036] The embodiment of the present invention provides a pre-pressing device, the pre-pressing device is mainly used in the plywood production line, in the production process, used for short-term cold pressing and preliminary bonding of the veneer after gluing and assembling , so that it is initially shaped, and then sent to the subsequent process. The pre-pressing device is an important device for improving the quality of plywood, and the pre-pressing device of the embodiment of the present invention will be introduced below.

[0037] Figure 1 to Figure 4 They are the overall view, the front view, the top view and the right view of the preloading device according to the first embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com