Arbitrary-angle automatic edge trimmer for V-shaped transmission belt

An arbitrary angle, transmission belt technology, used in metal processing and other directions, can solve problems such as low production efficiency, large dust pollution, and easy injury to operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

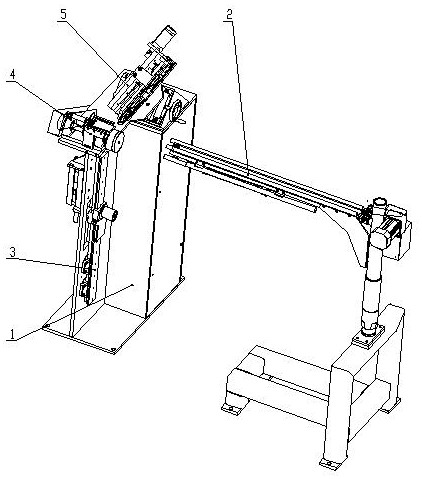

[0031] V-shaped transmission belt automatic edge trimmer at any angle, including automatic belt feeding device 2, automatic belt tensioning and rotating device 3, 4, automatic knife cutting device 5, said belt feeding device 2 will hang a row of untrimmed semi-finished products The belt is pushed to the belt tensioning device one by one. When the belt is tensioned and rotating, the edge trimming device automatically feeds the knife through the control of the servo motor to complete the cutting of the belt edge at a specified angle.

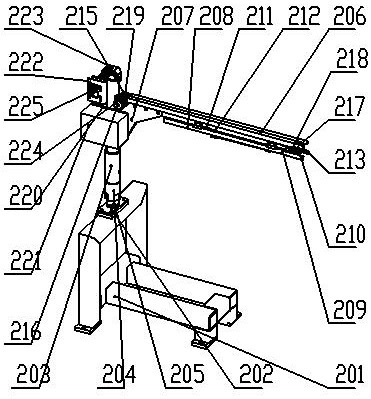

[0032] The structure of the belt feeding device is as follows: the belt feeding frame is vertically connected upward to an adjustable telescopic support column, and the top of the telescopic support column is provided with a hanging belt horizontal bar extending horizontally toward the edge trimming device. The hanging belt horizontal bar has There are two upper and lower layers. The upper layer hangs a row of semi-finished belts and is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com