Processing method of V-shaped transmission belt

A processing method and transmission belt technology, applied in metal processing and other directions, can solve the problems of low production efficiency, easy injury to operators, and large dust pollution, and achieve the effects of high production efficiency, elimination of dust pollution, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

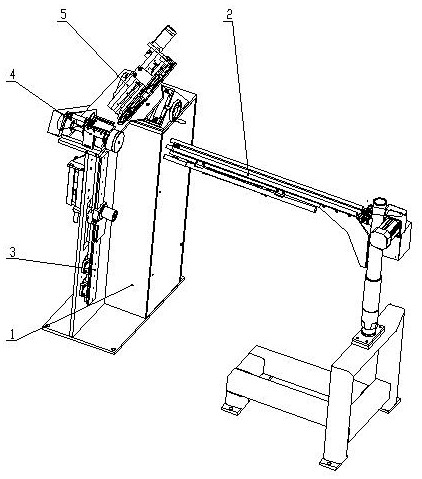

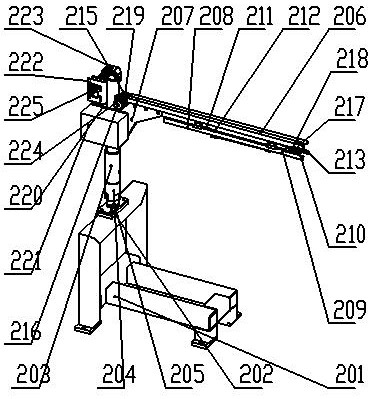

[0030] A method for processing a V-shaped transmission belt, comprising the following steps: automatically send the semi-finished belt with a rectangular cross-section to the outside through a belt feeding device to the two active and passive tension pulleys of the trimming machine, After the tension wheel receives the signal, it automatically tensions and rotates the semi-finished belt at a high speed. The cutting knife driving device at the corresponding position receives the instruction and performs bevel cutting at a specified angle, and finally completes the bevel processing of the V-shaped transmission belt.

[0031] The specific steps include: a. Cutting the vulcanized barrel belt into a group of semi-finished belts with a rectangular section in advance;

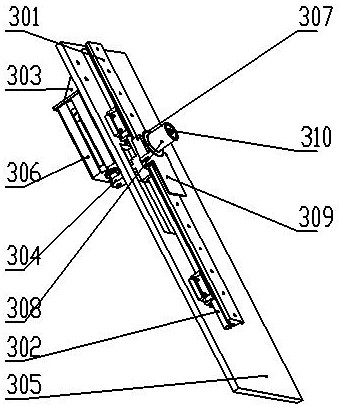

[0032] b. Hang the groups of semi-finished belts with the bottom glue facing outward on the hanger of the belt feeding device, so that each semi-finished belt is in a separated state, and the pushing device completes p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com