Blast furnace gas desulfurization purification system and method

A blast furnace gas and purification system technology, which is applied in combustible gas purification, combustible gas purification/transformation, combustion methods, etc., can solve problems such as large water consumption, excessive SO2 content, low pressure, etc., to save resources and improve product utilization. , the effect of improving the adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

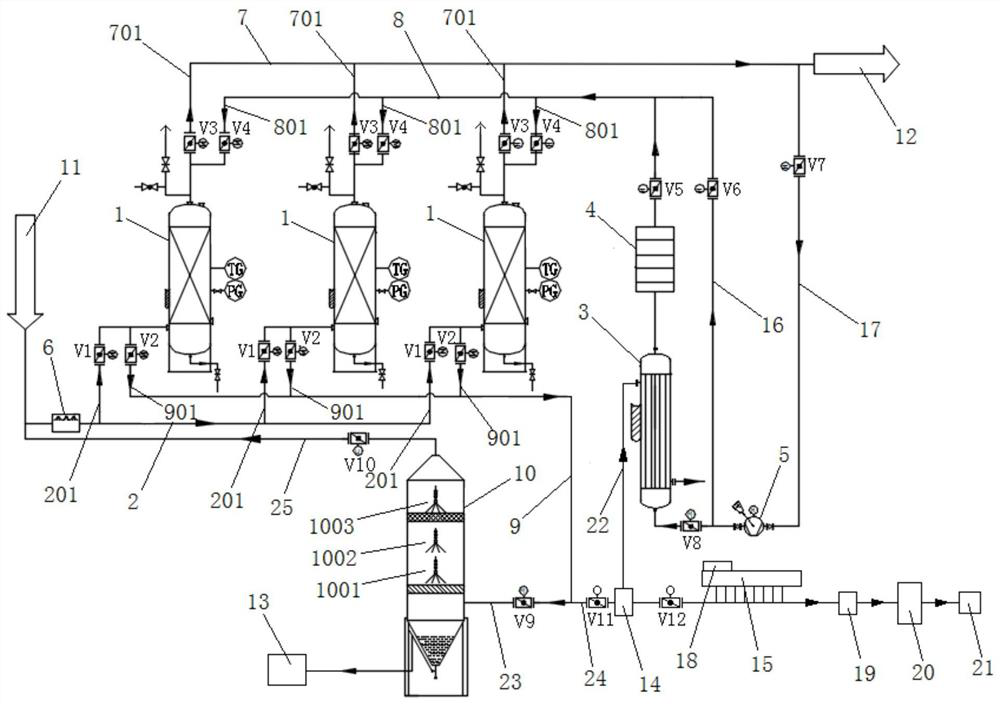

[0070] like figure 1 As shown, the present invention provides a blast furnace gas desulfurization purification system. The blast furnace gas desulfurization purification system includes a heating device, an alkali spray tower 10, a sintering device and a plurality of adsorption towers 1, wherein: each adsorption tower 1 is provided with filler The packing layer is filled with purification media, the air inlets of each adsorption tower 1 are respectively connected to one end of the corresponding blast furnace gas inlet branch pipe 201, and the other end of each blast furnace gas inlet branch pipe 201 is connected to the blast furnace gas inlet main pipe 2 connection, the blast furnace gas inlet main pipe 2 is connected with the gas outlet of TRT (Blast Furnace Gas Residual Pressure Turbine Generator) 11, and the gas outlets of each adsorption tower 1 are respectively connected with one end of the corresponding clean gas outlet branch pipe 701, each clean gas outlet The other en...

Embodiment 2

[0102] The present invention provides a blast furnace gas desulfurization purification method, the blast furnace gas desulfurization purification method uses the above-mentioned blast furnace gas desulfurization purification system, which includes the following steps:

[0103] Step S1: transporting the blast furnace gas to the adsorption tower 1 to adsorb inorganic sulfur and organic sulfur in the blast furnace gas to obtain clean blast furnace gas;

[0104] Step S2: After the adsorption tower 1 reaches the preset level, the clean blast furnace gas heated by the heating device is used as the regenerative gas to regenerate the adsorption tower 1. After the adsorption tower 1 is heated by the regeneration gas to the set temperature, the heat preservation process is carried out. The adsorbed inorganic sulfur and organic sulfur are desorbed, and the organic sulfur is catalyzed into inorganic sulfur in situ; the heated clean blast furnace gas is cut off, and the adsorption tower 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com