Composition for forming elastomer, elastomer formed by composition and application of elastomer

A composition and elastomer technology, which is applied in the field of elastomer-forming compositions and elastomers, can solve problems such as complex process flow and unrecyclable leftover materials, so as to simplify the process flow, avoid problems that cannot be recycled and reused, and reduce production The effect of craft and package process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] In this example, the following components were used to prepare elastomers:

[0085] Styrene-ethylene-butadiene-styrene block copolymer 100kg, mineral oil 150kg, calcium carbonate 40kg, polypropylene 20kg, ethylene-octene copolymer 10kg, calcium stearate 5kg, dibutylhydroxytoluene 0.5 kg, erucamide 5kg, UV absorber 0.3kg.

[0086] In this example, the above-mentioned raw materials were used to prepare elastomers by the following method:

[0087] (1) Fully mix the styrene-ethylene-butylene-styrene block copolymer with mineral oil and leave it for 10 hours;

[0088] (2) the mixture prepared by step (1) is uniformly mixed with the above-mentioned remaining raw materials by a high-speed mixer;

[0089] (3) Add the mixed raw materials into a twin-screw extruder, plasticize them uniformly in the screw extruder at 200° C., and prepare elastomer granules through underwater die granulation equipment;

[0090] (4) Dry and pack the elastomer particles into storage.

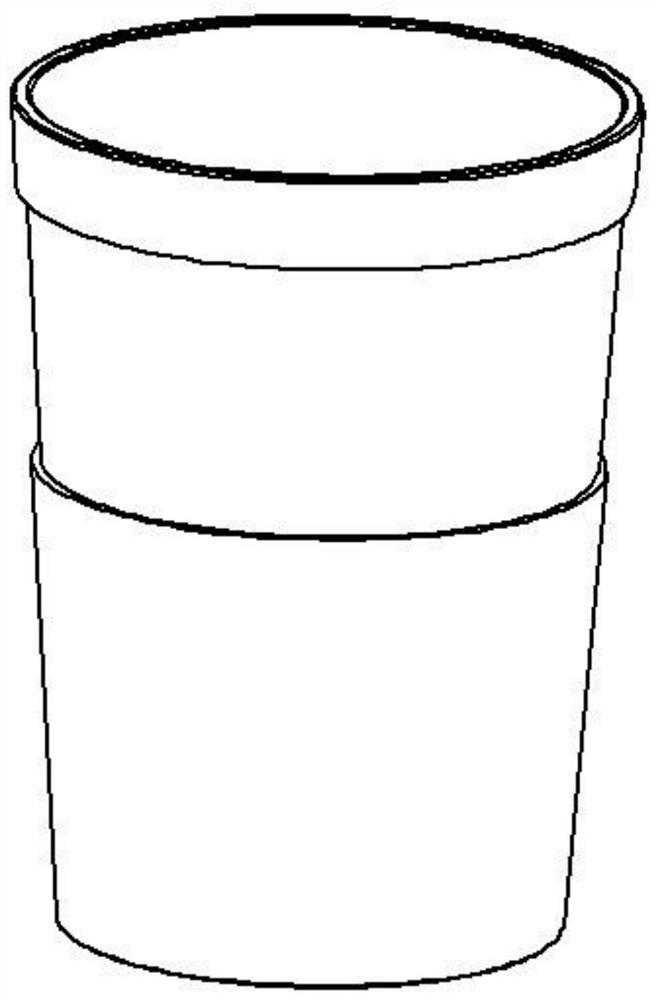

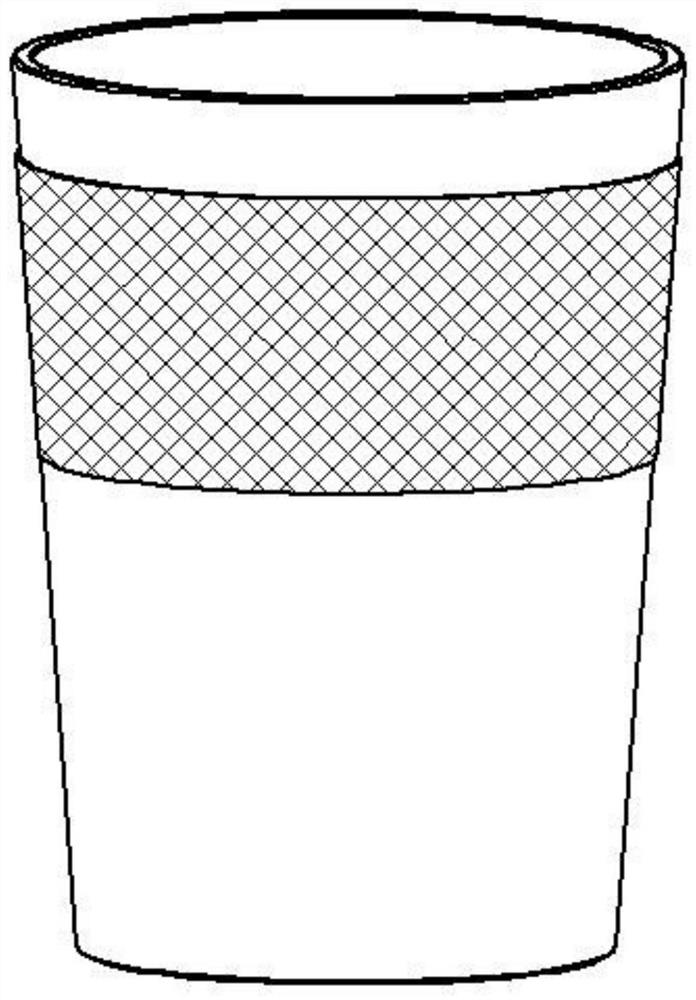

[0091] Usi...

Embodiment 2

[0096] In this example, the following components were used to prepare elastomers:

[0097] Styrene-ethylene-butylene-styrene block copolymer 100kg, mineral oil 145kg, calcium carbonate 38kg, polypropylene 18kg, ethylene-octene copolymer 9kg, calcium stearate 4.5kg, dibutylhydroxytoluene 0.45 kg, erucamide 4.5kg, UV absorber 0.25kg.

[0098] The preparation method of the elastomer and the integrated juice cup is the same as in Example 1. The results show that the processing performance, cohesive force and touch of the integrated juice cup prepared in this example are similar to those of the juice cup prepared in Example 1. The specific test results are shown in Table 1.

Embodiment 3

[0100] In this example, the following components were used to prepare elastomers:

[0101] Styrene-ethylene-butylene-styrene block copolymer 100kg, mineral oil 155kg, calcium carbonate 42kg, polypropylene 22kg, ethylene-octene copolymer 11kg, calcium stearate 5.5kg, dibutylhydroxytoluene 0.55 kg, erucamide 5.5kg, UV absorber 0.35kg.

[0102] The preparation method of the elastomer and the integrated juice cup is the same as in Example 1. The results show that the processing performance, cohesive force and touch of the integrated juice cup prepared in this example are similar to those of the juice cup prepared in Example 1. The specific test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com