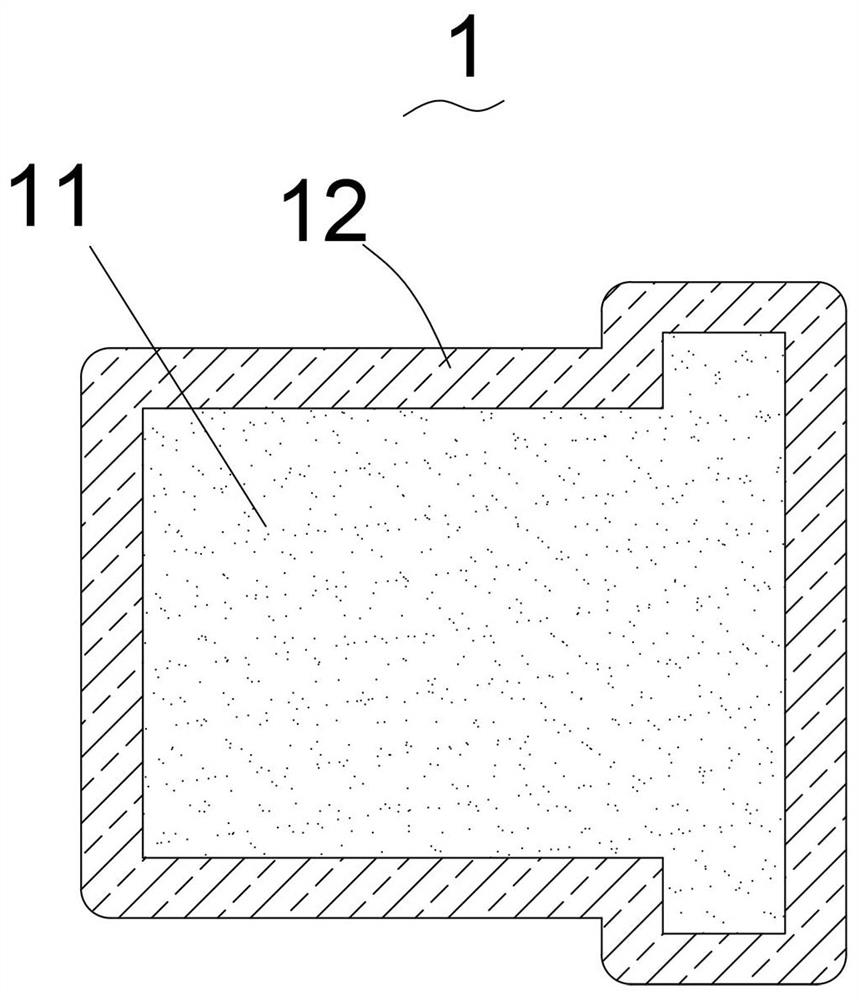

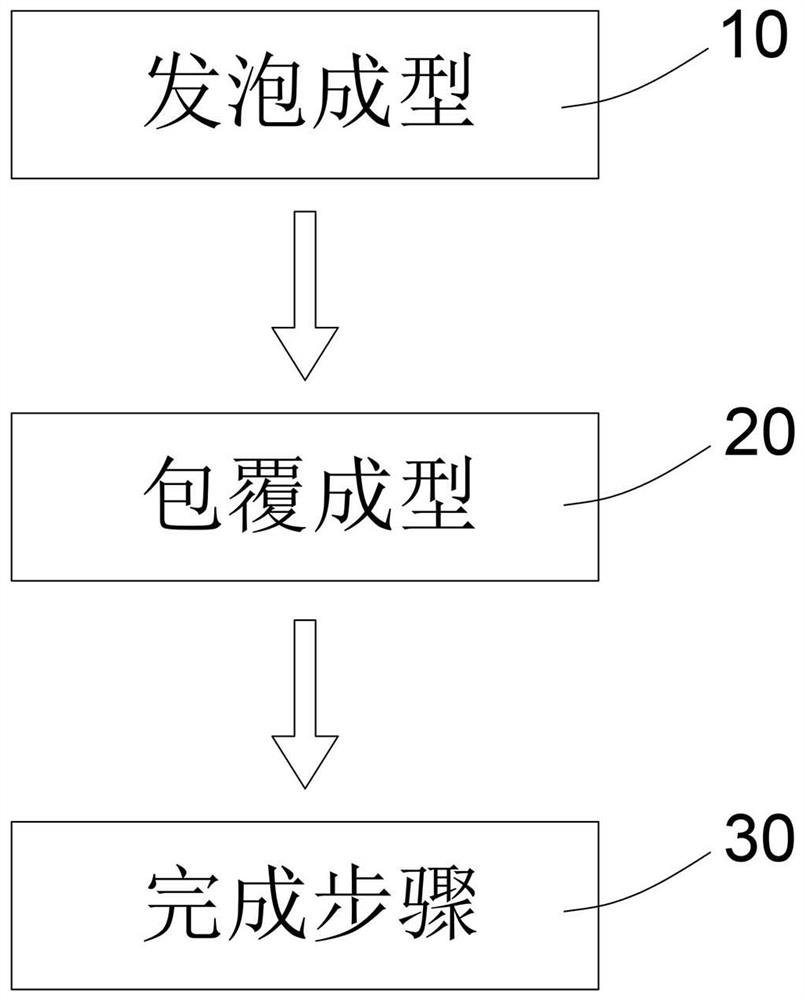

Elastomer for high and low temperature test chamber and manufacturing method of elastomer

A technology of high and low temperature test chambers and elastomers, applied in the field of polymer materials, can solve problems such as insufficient elasticity, short service life, and bulky body shape, and achieve the effect of improving workability, high and low temperature resistance, and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Described foam material is taken by following parts:

[0062] Polyether polyol 330N: 7 parts

[0063] Polyether polyol 3628: 3 parts

[0064] Catalyst A33: 0.4 parts

[0065] Catalyst A300: 0.2 parts

[0066] DMEA: 0.5 parts

[0067] Ethylene glycol: 600 parts

[0068] Second B: 1.0 parts

[0069] Cell opener: 1.0 parts

[0070] Water: 0.6 parts

[0071] Foaming agent: 12 parts.

[0072] It can be seen from the test that the foamed inner core obtained in the above examples has super strong resilience and air permeability, low post-encounter loss, high compression load ratio, and also has good heat resistance and fatigue resistance. The pore diameters are mixed and distributed, the skeleton thickness is different, and there is a large opening rate. It is used to make hole plugs suitable for high and low temperature test chambers after coating the outer layer of silica gel. The hole plugs can withstand high temperatures of 220~260 degrees, and low temperatures can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com