Pretreatment method for waste incineration fly ash

A technology for waste incineration fly ash and pretreatment, which is applied in chemical instruments and methods, solid waste removal, cement production, etc., to achieve the effects of resource saving, short process and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1. In this embodiment, fly ash from a waste incineration power generation enterprise in Hunan is used as a sample. The main components of the samples are listed in Table 1.

[0057] Table 1 Composition (%) of domestic waste incineration fly ash

[0058] Element Al 2 o 3

SiO 2

Fe 2 o 3

CaO K 2 o

Na 2 o

SO 3

Cl C content 9.0 20.3 5.0 26.6 4.2 5.8 6.5 12.5 9.1

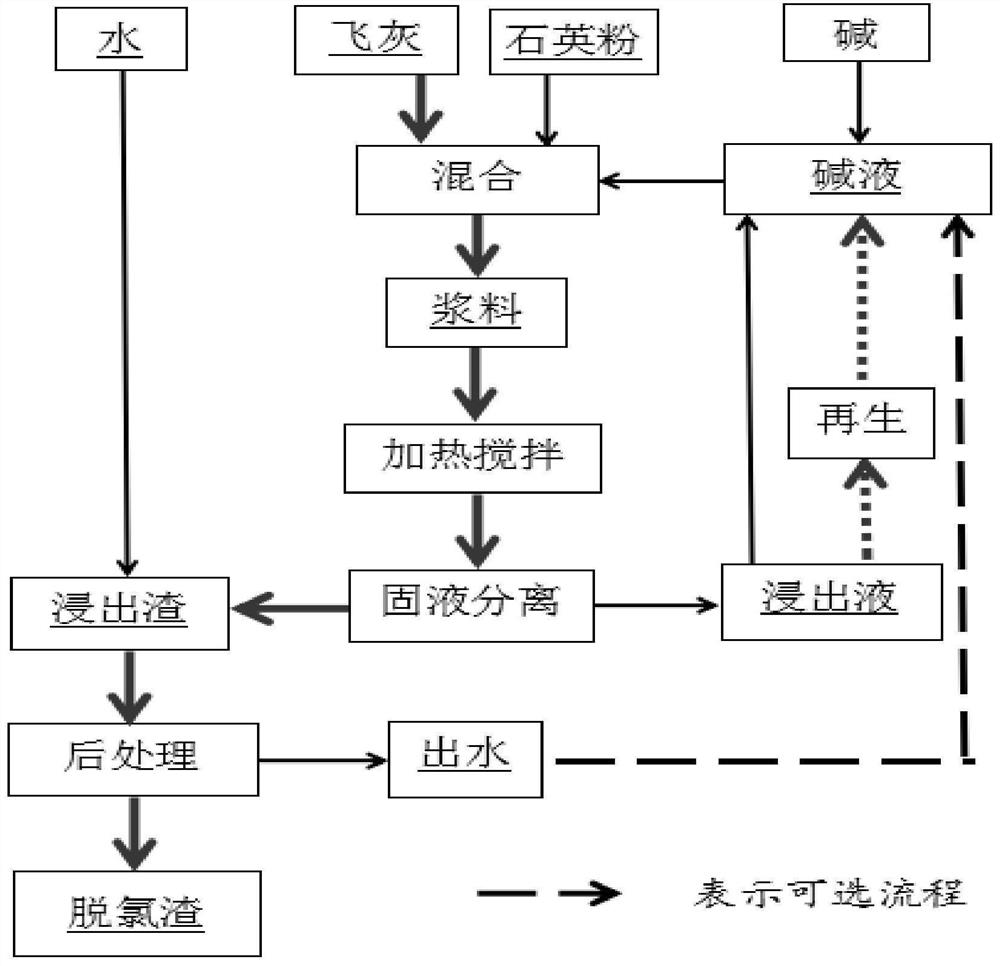

[0059] Such as figure 1 Shown, the pretreatment method of waste incineration fly ash of the present invention comprises the steps:

[0060] 1. After mixing fly ash and river sand powder, add it to lye and stir evenly to obtain a slurry; the mass ratio of each component in the slurry is fly ash: river sand powder: sodium hydroxide: water = 100:35: 35:1000; Among them: the silica content of river sand powder is 88.1%, the particle size is -0.075mm, 86.5%.

[0061] 2. Put the slurry into the reaction kettle, start the mixer, set th...

Embodiment 2

[0064] Embodiment 2, the fly ash sample of this embodiment is the same as that of Embodiment 1.

[0065] As a method for pretreatment of waste incineration fly ash according to an embodiment of the present invention, the method comprises the following steps:

[0066] 1. After the fly ash and quartz powder are combined, add to the lye and stir evenly to obtain a slurry; the mass ratio of each component in the slurry is fly ash:quartz powder:sodium hydroxide:water=100:30:35: 1000; Among them: the silica content of quartz powder is 90.6%, the particle size is -0.075mm, 85.2%.

[0067] 2. Put the slurry into the reaction kettle, start the mixer, set the speed at 100 rpm, heat the slurry to 95°C-100°C with an electric heater, keep it warm and continue stirring for 120 minutes.

[0068] 3. Vacuum suction filtration of the reacted slurry to obtain a primary filter cake and leachate.

[0069] 4. Wash the water and the primary filter cake with water for 1 pass according to the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com