Bauxite treatment method

A processing method and bauxite technology, applied in grain processing, solid separation, flotation, etc., can solve problems such as high cost and complex ore components, and achieve the effect of increasing electrostatic repulsion and preventing flocculation and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, the bauxite raw ore is directly flotation-processed. Put the bauxite raw ore into a ball mill, grind it until the particle size is -200 mesh, and account for 85%, and then transfer it to the stirring tank. The concentration of the prepared pulp (i.e., solid content) is 30%. , and then transferred to a 1.5L flotation tank for flotation desiliconization, adjust the pH of the pulp to 9.0 with sodium carbonate and add a collector to carry out flotation. The flotation collector is sodium oleate, and the dosage is 1200g / t raw ore, according to the conventional flotation operation, the recovery rate of alumina in the concentrate obtained by flotation is 75.39%, the recovery rate of silicon oxide is 50.43%, and the aluminum-silicon ratio of the concentrate is 8.02.

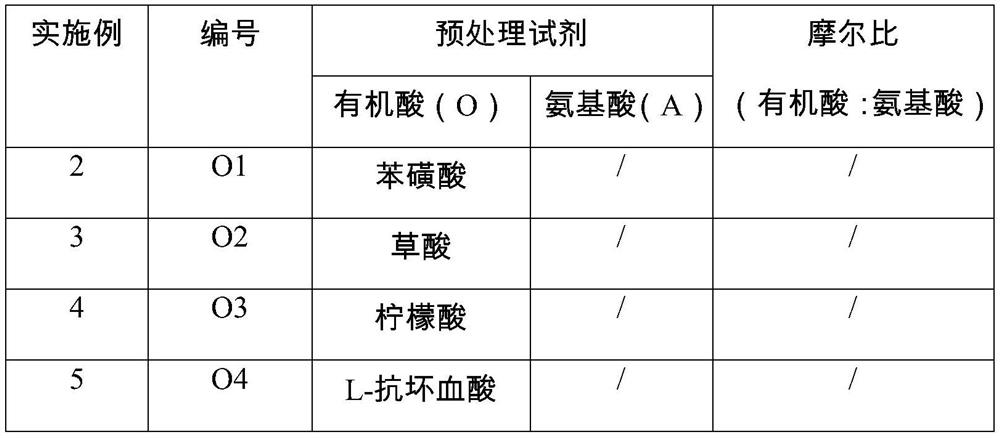

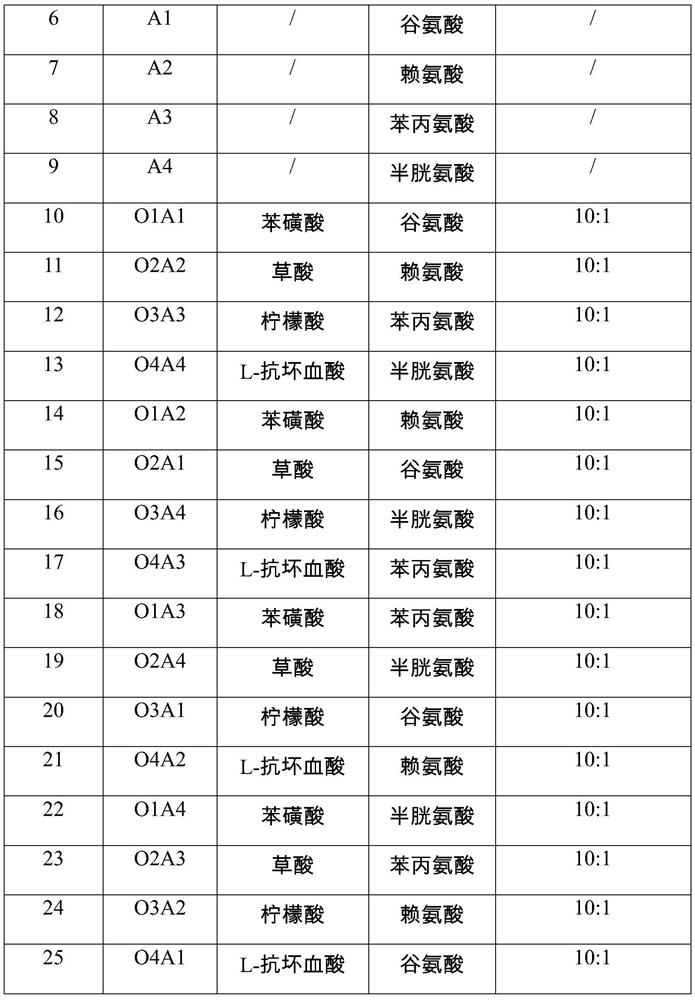

[0041] Following embodiment 2-25 carries out pretreatment earlier before bauxite flotation, and the method for processing is specifically:

[0042] The bauxite raw ore is mixed with the pretreatme...

Embodiment 26

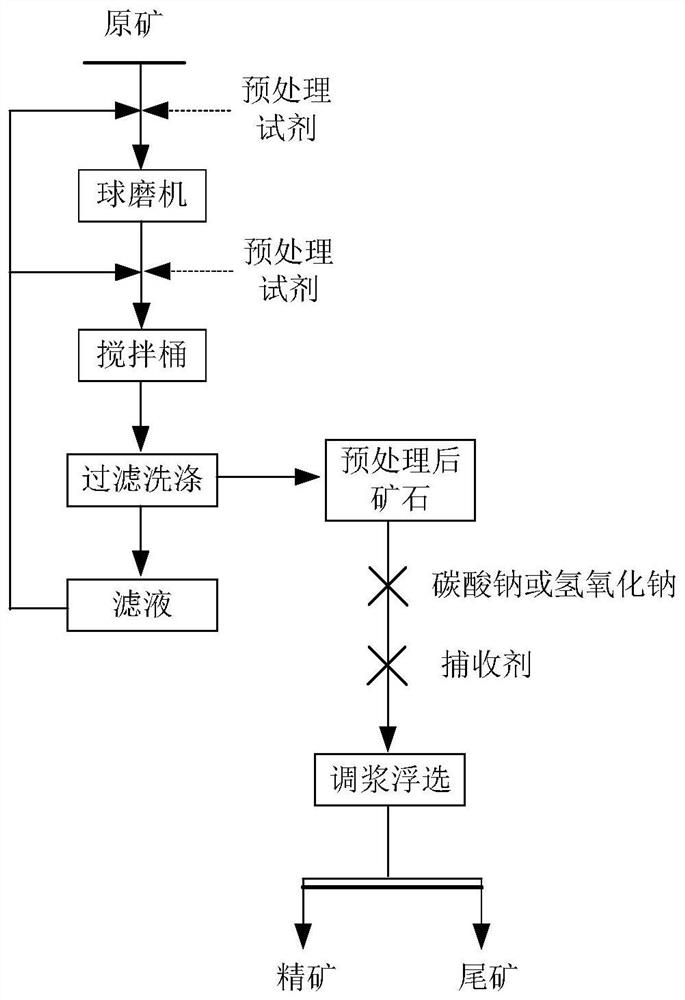

[0055] This embodiment has all added pretreatment reagent before ore grinding and after grinding, and this embodiment adopts figure 1 The process shown is to treat bauxite. The pretreatment reagent used is mixed with oxalic acid and phenylalanine at a molar ratio of 10:1. The specific treatment method is as follows:

[0056] Mix the bauxite raw ore and the pretreatment reagent into the ball mill, the amount of the pretreatment reagent is 800g per ton of raw ore, and grind to a particle size of -200 mesh, accounting for 85%;

[0057] Transfer the minerals from the ball mill to the stirring tank, adjust the concentration of the pulp to 30%, then add the pretreatment reagent to the slurry, the amount of the pretreatment reagent is based on the minerals contained in the pulp, add 200g per ton of minerals, and then Stirring at ℃ for 2h;

[0058] After filtering, the obtained solids are washed to obtain pretreated bauxite minerals, and the obtained filtrate and washing liquid are r...

Embodiment 27

[0062] In this embodiment, a pretreatment reagent is added after grinding. The pretreatment reagent used in this embodiment is mixed with oxalic acid and phenylalanine at a molar ratio of 10:1. The processing method is specifically:

[0063] Put the bauxite raw ore into the ball mill, and grind it to a particle size of -200 mesh, accounting for 85%;

[0064] Transfer the minerals from the ball mill to the stirring tank, adjust the concentration of the pulp to 30%, then add the pretreatment reagent to the slurry, the amount of the pretreatment reagent is based on the minerals contained in the pulp, add 1000g per ton of minerals, and then Stirring at ℃ for 2h;

[0065] After filtering, the obtained solids are washed to obtain pretreated bauxite minerals, and the obtained filtrate and washing liquid are returned to be used as pretreatment reagents;

[0066] Prepare the pretreated bauxite minerals into 30% concentration flotation slurry, transfer it to a 1.5L flotation tank for f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com