Bentonite cat litter capable of being flushed in toilet and preparation method thereof

A technology of bentonite and cat litter, applied in animal houses, applications, animal husbandry, etc., can solve problems such as inability to flush toilets, troublesome handling, slow dissolution of hard lumps, etc., to achieve improved water absorption, low cost, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of bentonite cat litter that can flush the toilet, select the bentonite that montmorillonite content is 69%, carry out drying, make the moisture content of bentonite be controlled at 15%, weigh 6.75t of bentonite after drying, then add 150Kg to bentonite with a purity of 99.7 % sodium carbonate and 3.1t zeolite, the standard of zeolite is ammonia absorption > 90.0mmol / 100g, moisture < 10%, mix well, transfer the mixture to Raymond machine for grinding, and grind until the fineness of the mixture is 200 Then add the ground mixture to the pelletizing disc, spray water to make wet balls, control the moisture content of the wet balls at 26%, transport the wet balls to the rotary drying furnace for drying, and set the furnace head temperature The temperature is 850°C, and the temperature at the end of the furnace is 180°C. After the drying is completed, the finished product is obtained, and the moisture content of the finished product is controlled at 3%.

Embodiment 2

[0030] A kind of bentonite cat litter that can flush the toilet, select the bentonite that montmorillonite content is 67%, carry out drying, make the moisture content of bentonite be controlled at 13%, weigh 6.65t of bentonite after drying, then add 120Kg to bentonite with a purity of 99.6 % of sodium carbonate and 3.3t zeolite, the standard of zeolite is ammonia absorption > 90.0mmol / 100g, moisture < 10%, mix evenly, transfer the mixture to Raymond machine for grinding, and grind until the particle size of the mixture is 190 mesh, then add the ground mixture to the pelletizing disc, spray water to make wet balls, control the moisture content of the wet balls at 25%, transport the wet balls to the rotary drying furnace for drying, and set the furnace head The temperature is 850°C, and the temperature at the end of the furnace is 180°C. After drying, the finished product is obtained, and the moisture content of the finished product is controlled at 3%.

Embodiment 3

[0032] A kind of bentonite cat litter that can flush the toilet, select the bentonite that montmorillonite content is 66%, carry out drying, make the moisture content of bentonite be controlled at 12%, weigh 6.5t of bentonite after drying, then add 180Kg to bentonite with a purity of 99.6 % sodium carbonate and 3.5t zeolite, the standard of zeolite is ammonia absorption > 90.0mmol / 100g, moisture < 10%, mix evenly, transfer the mixture to Raymond machine for grinding, and grind until the fineness of the mixture is 190 Then add the ground mixture to the pelletizing disc, spray water to make wet balls, control the moisture content of the wet balls at 28%, transport the wet balls to the rotary drying furnace for drying, and set the furnace head temperature The temperature is 850°C, and the temperature at the end of the furnace is 180°C. After the drying is completed, the finished product is obtained, and the moisture content of the finished product is controlled at 3%.

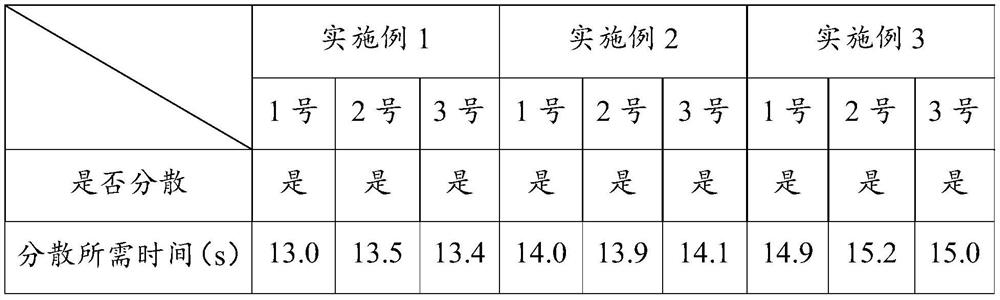

[0033] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com