Cable and wire core wiring method thereof

A wiring method and cable technology, applied in the direction of circuits, connections, electrical components, etc., can solve problems such as improper cooperation between the crimping die and the surface of the connecting pipe, breakdown, and puncture of the cable insulator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] refer to Figure 6 As shown, the present invention provides a cable core 200 wiring method, the method includes the following steps:

[0041] Step S110 : Insert the cores 200 of the two cables into the connecting tube 100 . Wherein, the connecting pipe 100 is made of metal, and its cross section is polygonal.

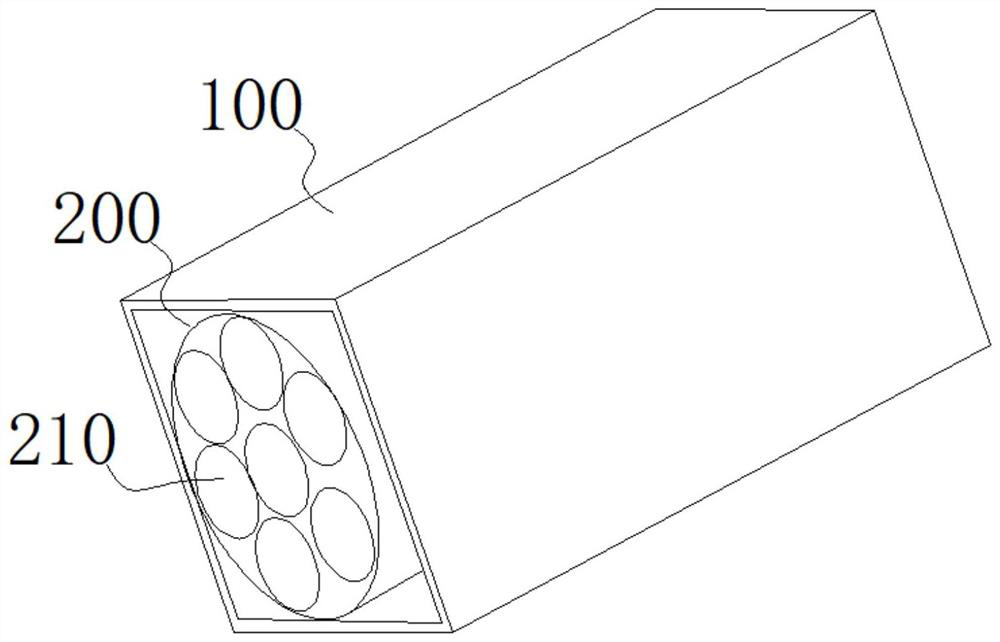

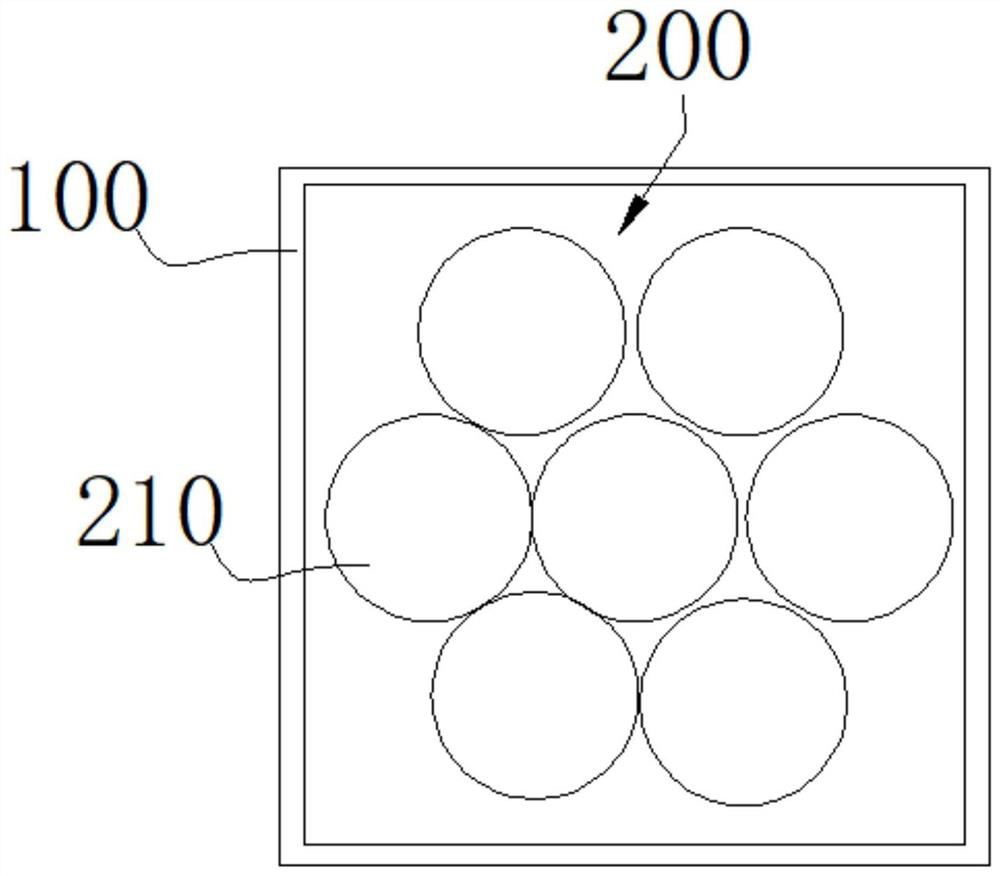

[0042] Such as figure 1 and figure 2 As shown, in this example, the connecting pipe 100 is a quadrangular metal pipe. Strip off the cable insulators at the ends of the two cables to expose the cable core 200, such as figure 2 As shown, a bundle of cable cores 200 is formed by winding seven wires 210, and the seven wires 210 can be misaligned (that is, can move relative to each other) when subjected to external extrusion.

[0043] Step S120: Use the crimping die 400 to press the connecting tube 100 radially from the outside to the inside, so that the connecting tube 100 is interference-fitted with the cores 200 of the two cables. Among them, such as Figu...

Embodiment 2

[0049] refer to Figure 7 As shown, the present invention provides a cable core 200 wiring method, the method includes the following steps:

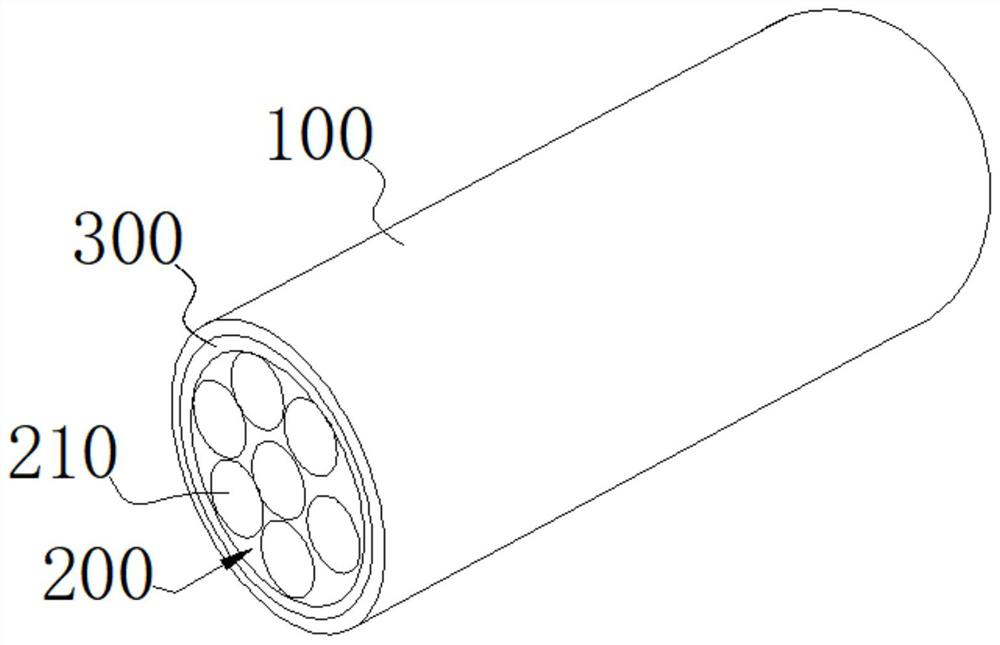

[0050] Step S210: inserting the embedded liner 300 into the connecting pipe 100; wherein, both the embedded liner 300 and the connecting pipe 100 are made of metal, and the cross section of the connecting pipe 100 is quadrilateral.

[0051] Step S220 : Insert the wire cores 200 of the two cables into the embedded liner 300 .

[0052] Step S230 : Use the crimping die 400 to press the connecting pipe 100 from outside to inside in the radial direction, so that the connecting pipe 100 is interference-fitted with the core 200 of the two-section cable and the embedded liner 300 . Among them, such as Figure 5 As shown, the crimping die 400 includes an upper die 410 and a lower die 420, and the upper die 410 and the lower die 420 can move up and down driven by a hydraulic mechanism. The lower end surface of the upper mold 410 has a first cri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com