Functional material, light-emitting substrate and preparation method thereof, and light-emitting device

A function and substrate technology, applied in the fields of light-emitting substrates and their preparation, light-emitting devices, materials with hole injection and/or hole transport functions, and can solve problems such as functional layer crystallization plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

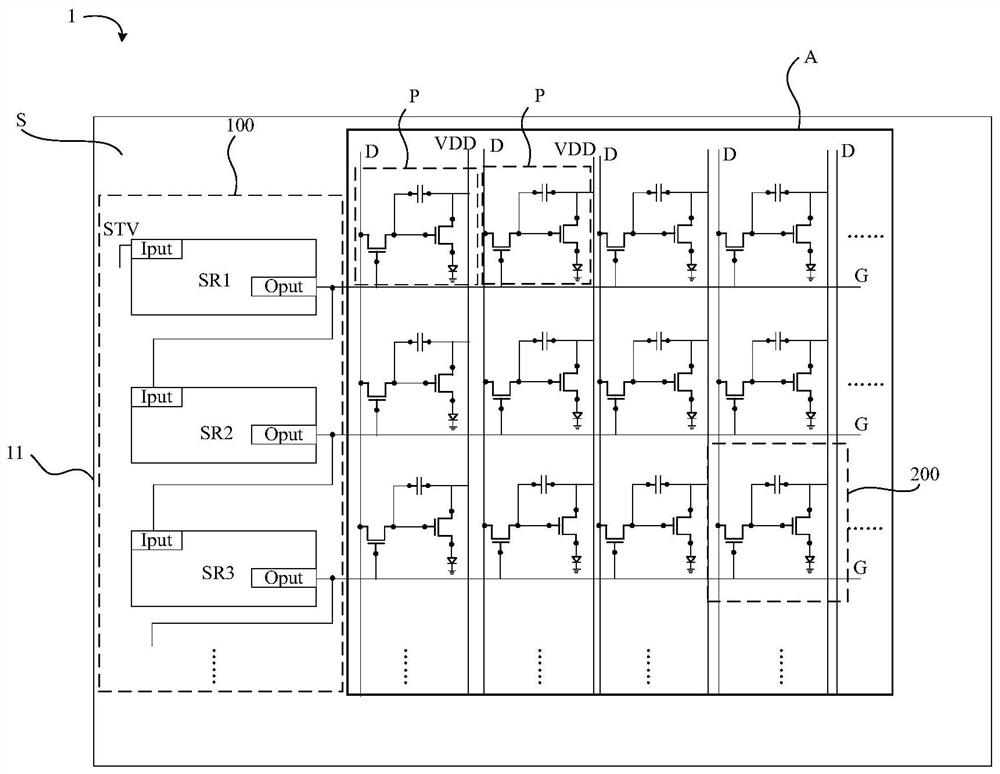

[0106] Some embodiments of the present disclosure provide a method for preparing a light-emitting substrate, including:

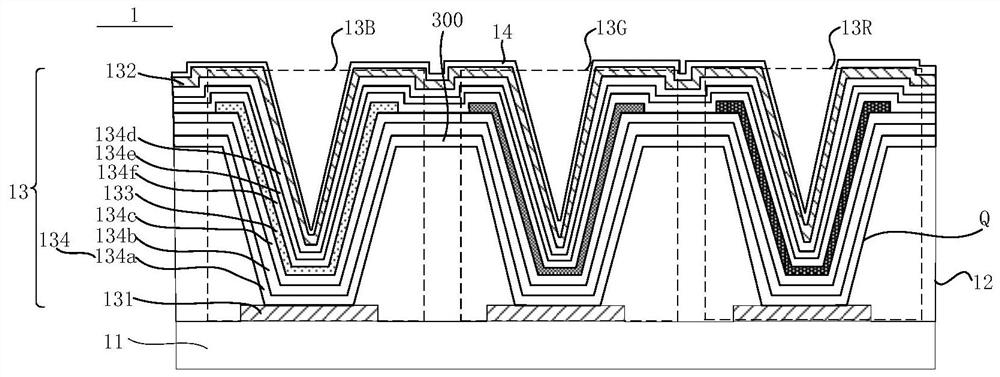

[0107] A plurality of light emitting devices 13 are formed on a substrate 11 . Wherein, the material of the functional layer 134 in at least one light-emitting device 13 is selected from the above-mentioned materials having hole injection and / or hole transport functions. The material with hole injection and / or hole transport functions includes a host material, and a crystallization inhibitor doped in the host material, the crystallization inhibitor can inhibit the crystallization of the host material during evaporation, and the crystallization inhibitor has voids hole injection and / or hole transport functions.

[0108] In some embodiments, in the case where the light emitting substrate 1 includes a pixel defining layer 12, and the pixel defining layer 12 has a plurality of openings Q, forming a plurality of light emitting devices 13 on the substrate 11 may...

experiment example 1

[0122] In Experimental Example 1, the material of the functional layer 134 is selected from a hole injection material and a crystallization inhibitor, wherein the hole injection material is the same as the hole injection material in Comparative Example 1, and the crystallization inhibitor is N,N'-diphenyl -N,N'-bis(3-methylphenyl)-1,1'-biphenyl-4,4'-diamine, the mass ratio of hole injection material and crystallization inhibitor is 90:10, by distilling Plating is performed on the substrate 11 on which the pixel defining layer 12 is formed to form a thin film having a hole injection function.

Embodiment 2

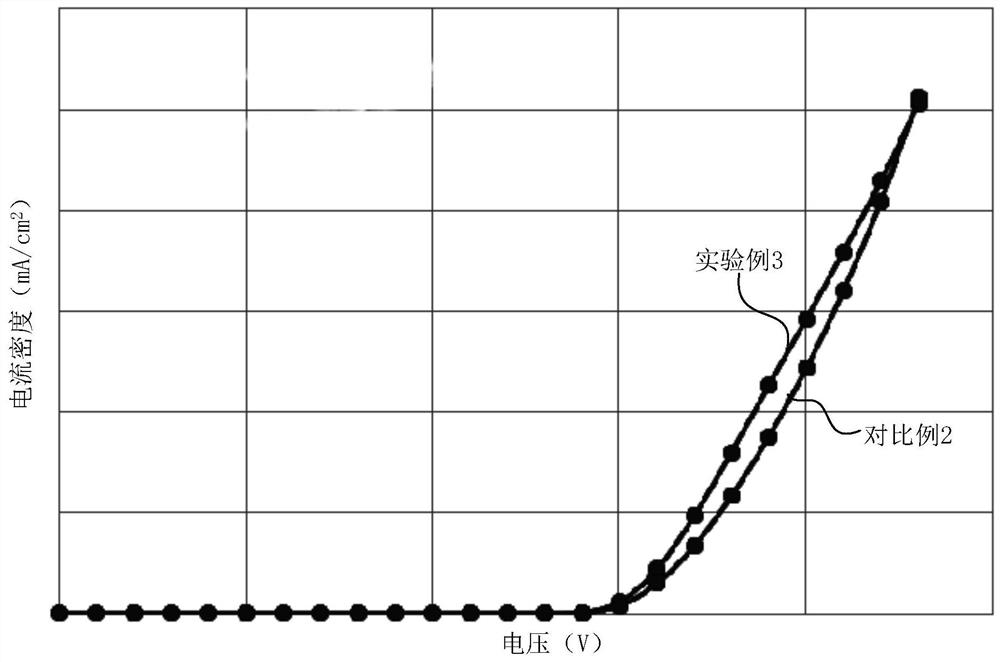

[0124] In Experimental Example 2, the material of the functional layer 134 is selected from a hole transport material and a crystallization inhibitor, wherein the hole transport material is the same as the hole transport material in Comparative Example 2, and the crystallization inhibitor is N,N'-diphenyl -N,N'-bis(3-methylphenyl)-1,1'-biphenyl-4,4'-diamine, the mass ratio of hole transport material and crystallization inhibitor is 97:3, by distilling Plating is performed on the substrate 11 on which the pixel defining layer 12 is formed to form a thin film having a hole injection function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com