Rock-fill dam material compaction quality detection method based on soil body rigidity

A technology of compaction quality and detection method, which is applied in the direction of measuring devices, analysis materials, strength characteristics, etc., can solve the problems of processing lag, the physical meaning of detection indicators is not clear enough, and the parameters of re-rolling and control standards are difficult to be re-determined. good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

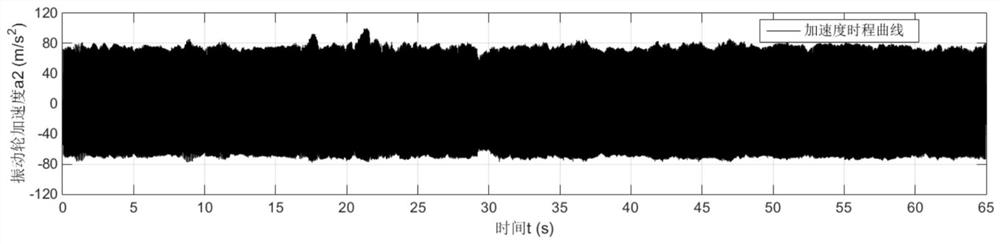

[0062] 1. The relationship between soil parameters and the acceleration of the vibration system

[0063] According to the theory and method of vibration structure modal analysis, combined with the rolling characteristics of rockfill dam materials, the frame and vibrating wheel of the vibratory rolling machine are simplified to lumped mass m 1 and m 2 , the damping device of the roller compactor uses the stiffness k 1 , damping c 1 to describe, and simplify the vibrating soil to a lumped mass m 3 , with a certain stiffness k s and linear damping c s ignoring the influence of soil hysteretic deformation characteristics and time, and establishing a three-degree-of-freedom dynamic analysis model of the "roller-soil" vibration system that can be applied to rockfill dam materials, such as figure 1 Shown in order to analyze the relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com