A compact low-speed centrifugal compressor

A centrifugal compressor, low-speed technology, used in mechanical equipment, non-variable-capacity pumps, non-displacement pumps, etc., can solve the problems of difficult diffuser diffusing, unsuitable size constraints, etc., to avoid flow loss. , reduce the loss of circulation, the effect of high boost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

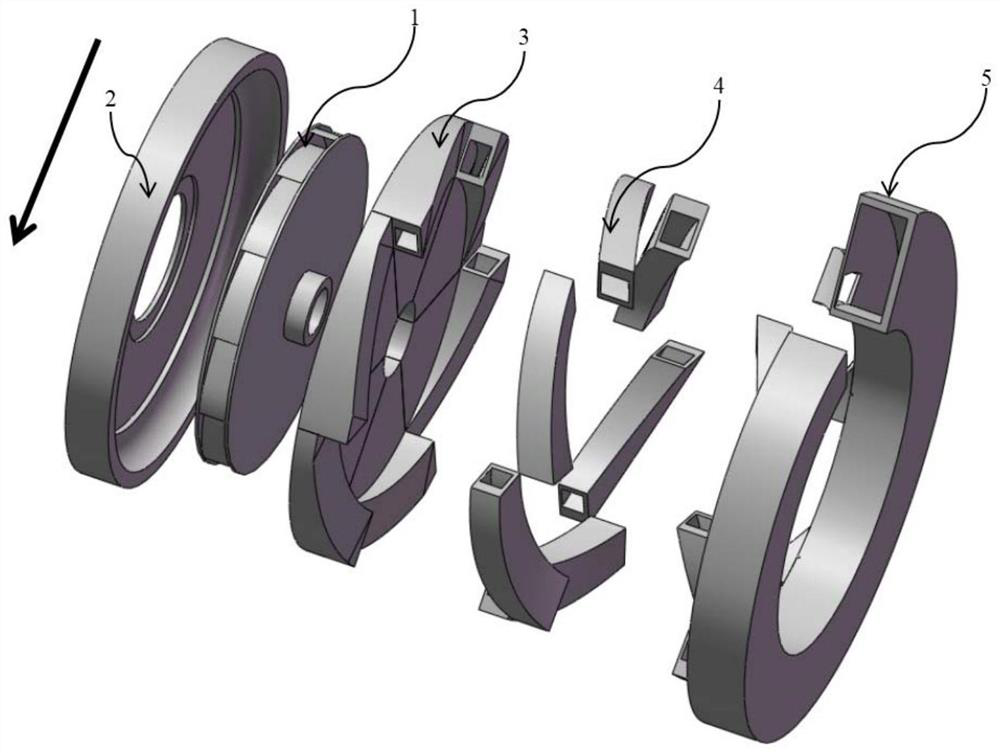

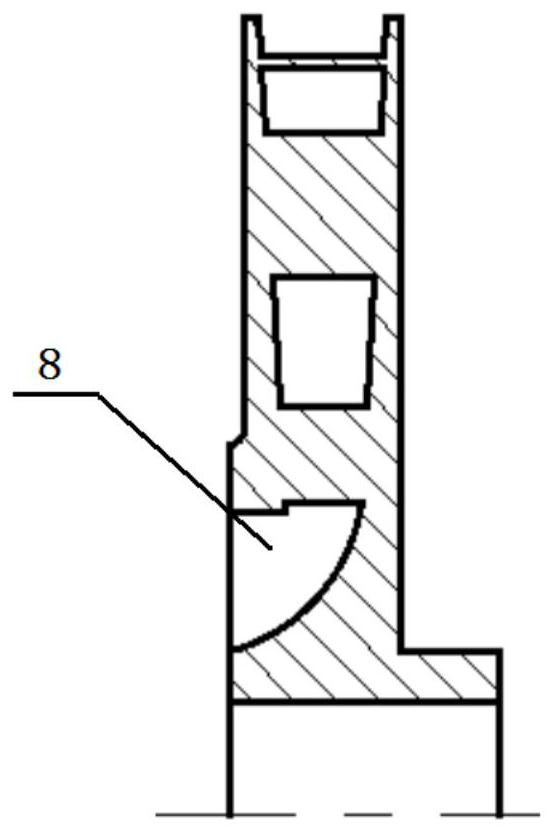

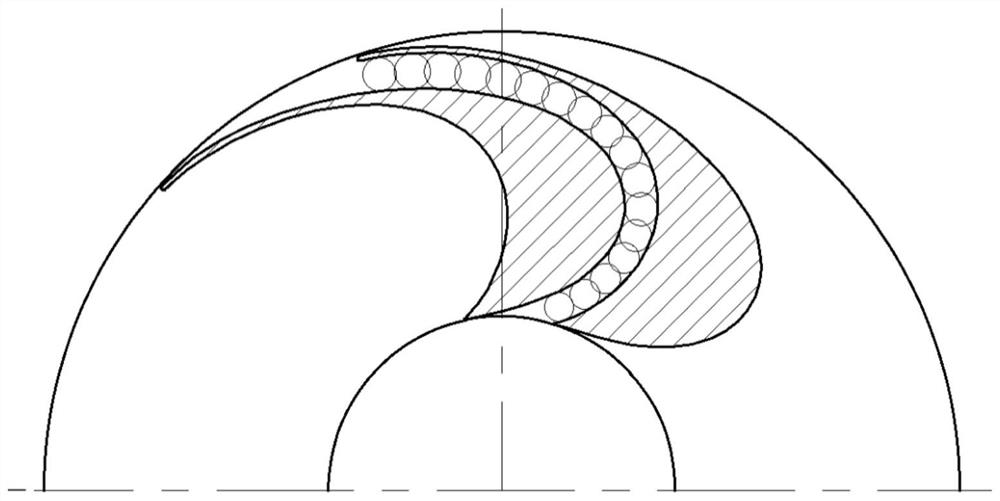

[0035] refer to Figure 1 to Figure 10 , the compact low-speed centrifugal compressor of the present invention includes a guide front cover 2, an impeller 1, a diffuser rear cover 3, a number of diffuser spiral passages 4 and a diffuser collector 5 arranged in sequence; The cover plate 2 is fastened on the diffuser rear cover plate 3, and a columnar cavity is formed between the guide front cover plate 2 and the diffuser rear cover plate 3, and the impeller 1 is located in the columnar cavity, the outer peripheral surface of the impeller 1, the guide An annular channel is formed between the front cover plate 2 and the diffuser rear cover plate 3, and an air inlet is provided on the guide front cover plate 2, and a gas channel 8 is arranged in the impeller 1; The side of the device 5 is provided with a plurality of diffuser back cover passages 6, the diffuser back cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com