A manufacturing method for a split-lobe runner of a large-scale impact water turbine

A manufacturing process, the technology of the split runner, which is applied in the field of the manufacturing process of the split runner of the large-scale impact water turbine, can solve the problems that the raw material of the runner cannot be forged, the limitation of the overall transportation of the runner, etc., so as to improve the welding production efficiency and prolong the service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

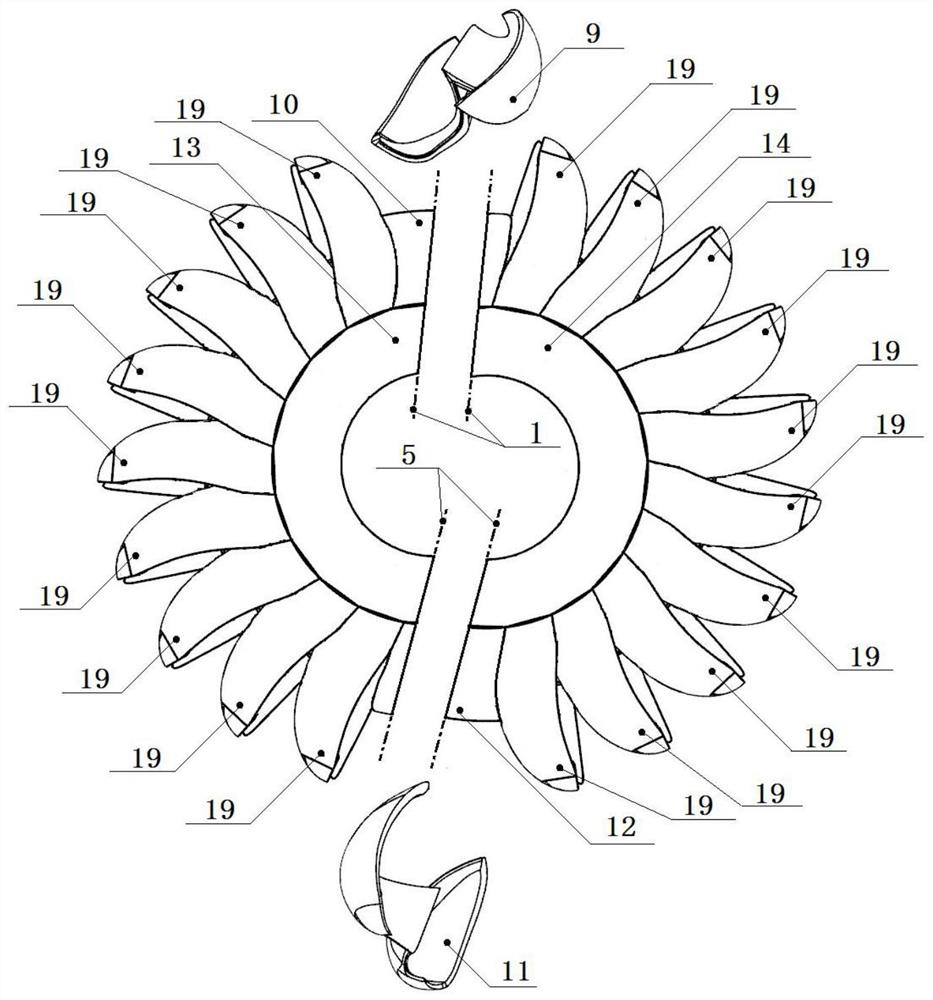

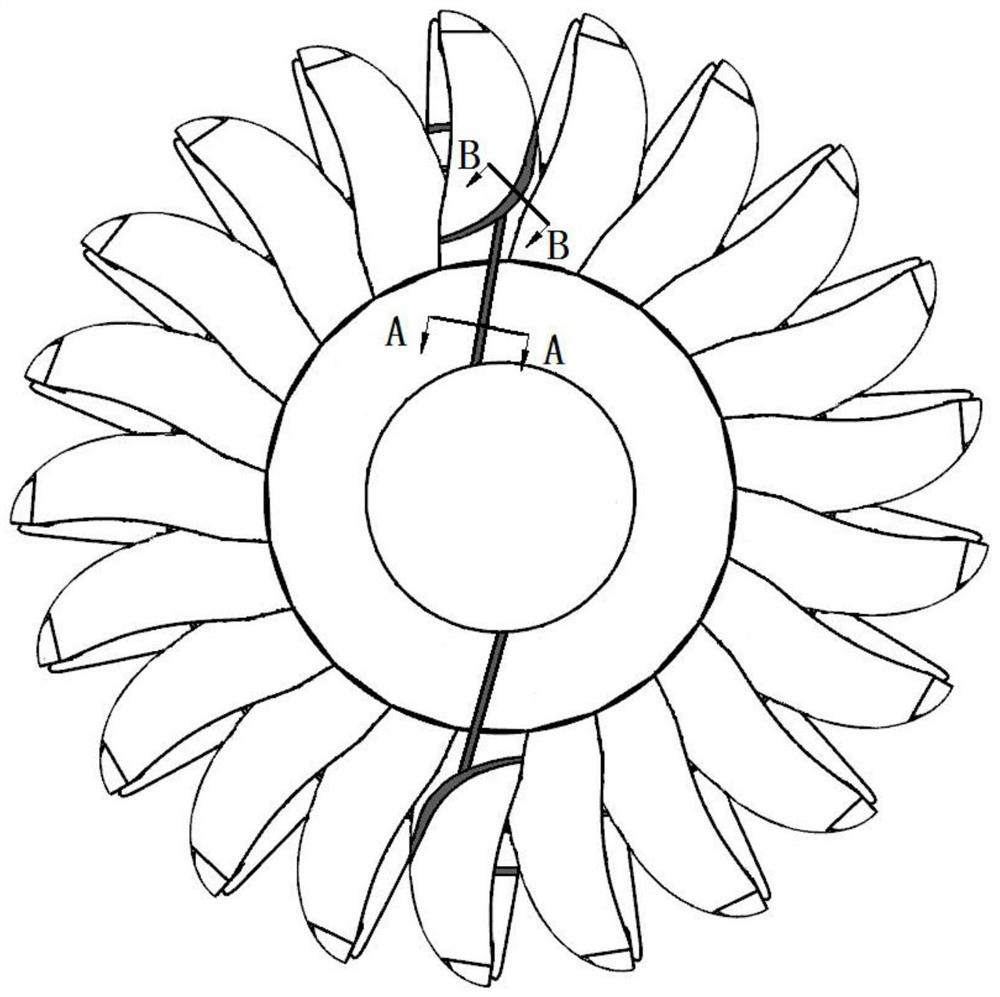

[0028] Step 1: The runner of the large-scale impingement water turbine manufactured by the split-lobe is made of martensitic forged steel, according to the split-lobe structure of the runner, such as figure 1 As shown, the first single lobe 13 of the runner, the second single lobe 14 of the runner, the first bucket end 9 and the second bucket end 11 of the runner split-lobe combined surface are respectively forged, and after forging, the The first single lobe 13 of the runner, the second single lobe 14 of the runner, the first bucket end 9 and the second bucket end 11 of the runner split-lobe combined surface are respectively CNC-machined;

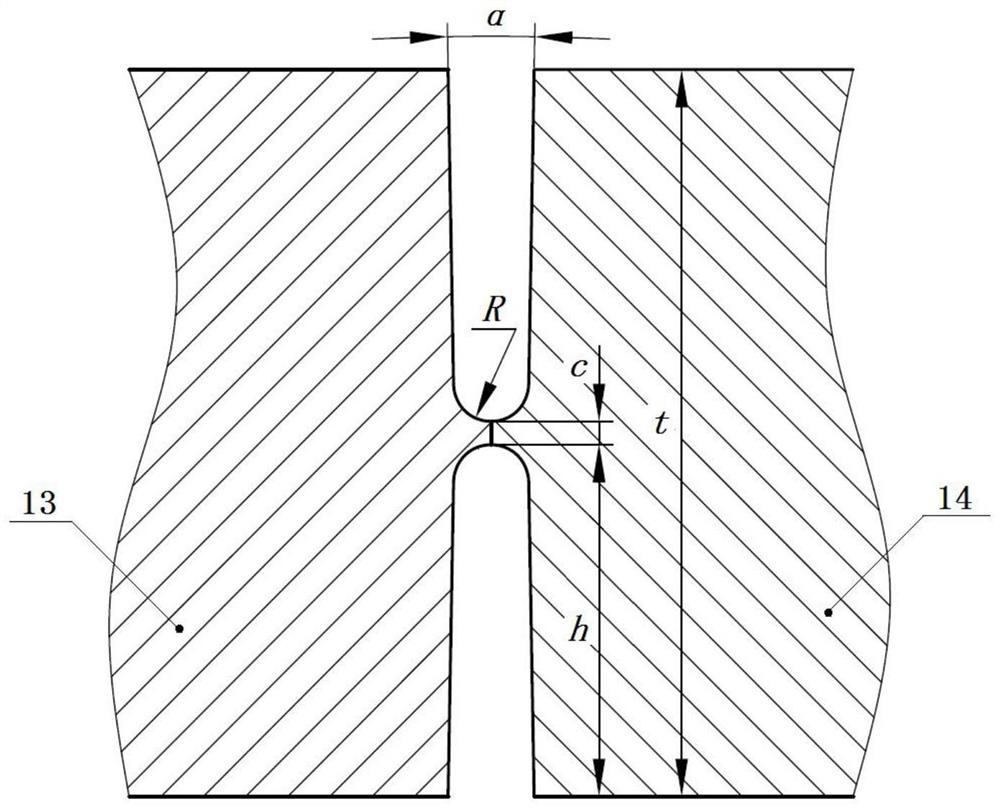

[0029] Step 2: During the CNC machining of the first single valve 13 of the runner and the second single valve 14 of the runner, except for the shape lines of the first bucket root 10 and the second bucket ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com