Binding pipe body and binding method of pipe body used of brazing

A brazing and pipe body technology, which is applied in non-detachable pipe connections, pipes/pipe joints/fittings, applications, etc., can solve problems such as uneven brazing space, reduced joint strength, and infiltration of filler metals to reduce filling The effect of increasing the amount of metal, increasing the bonding strength, and increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, a bonded pipe body and a bonding method using brazed pipe bodies according to the present invention will be described in detail with reference to the accompanying drawings.

[0056] First of all, it should be noted that as many as possible identical parts or components in the figures are denoted by the same reference numerals. In the description of the present invention, detailed descriptions of related known functions or structures are omitted in order to prevent the gist of the present invention from being unclear.

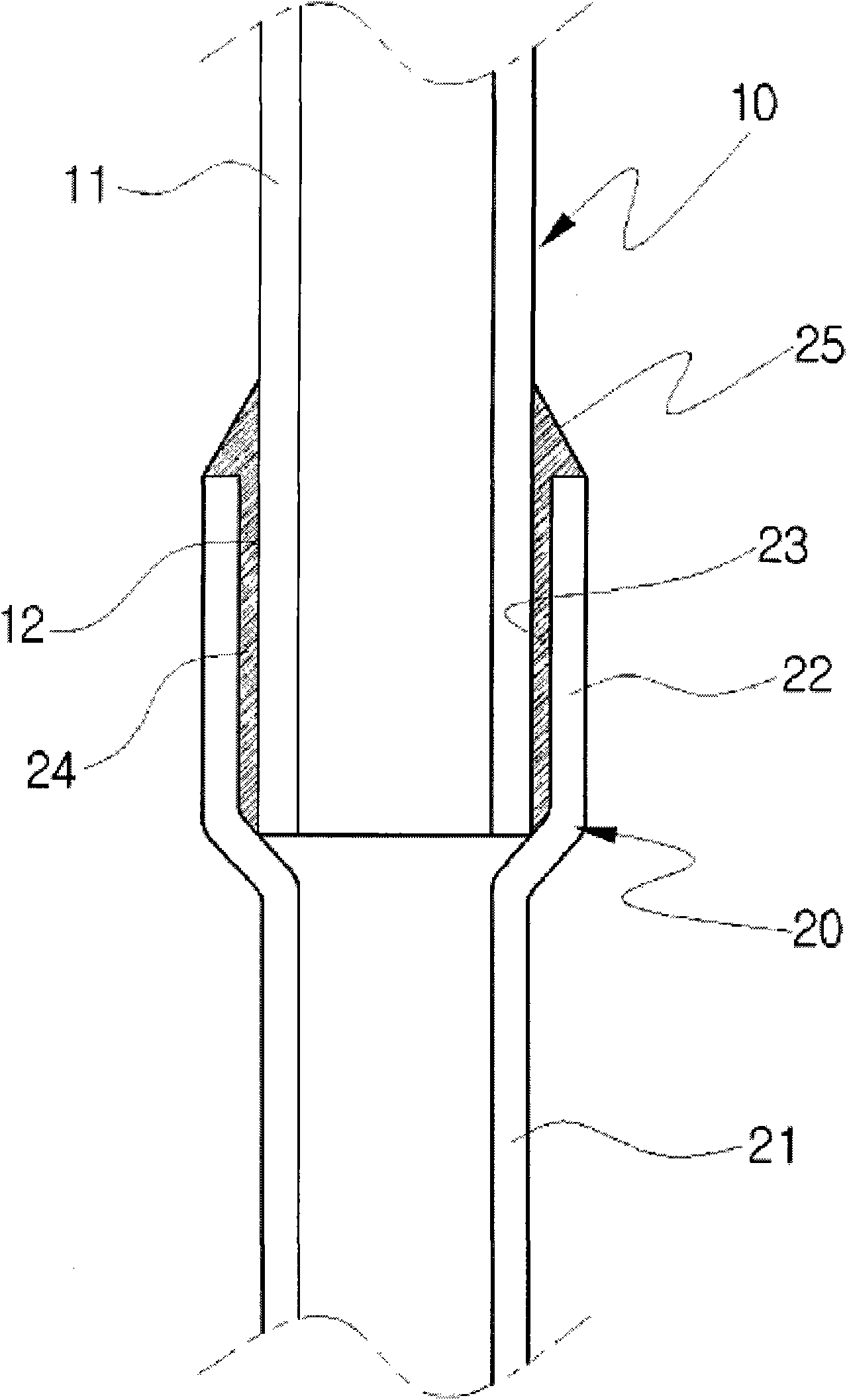

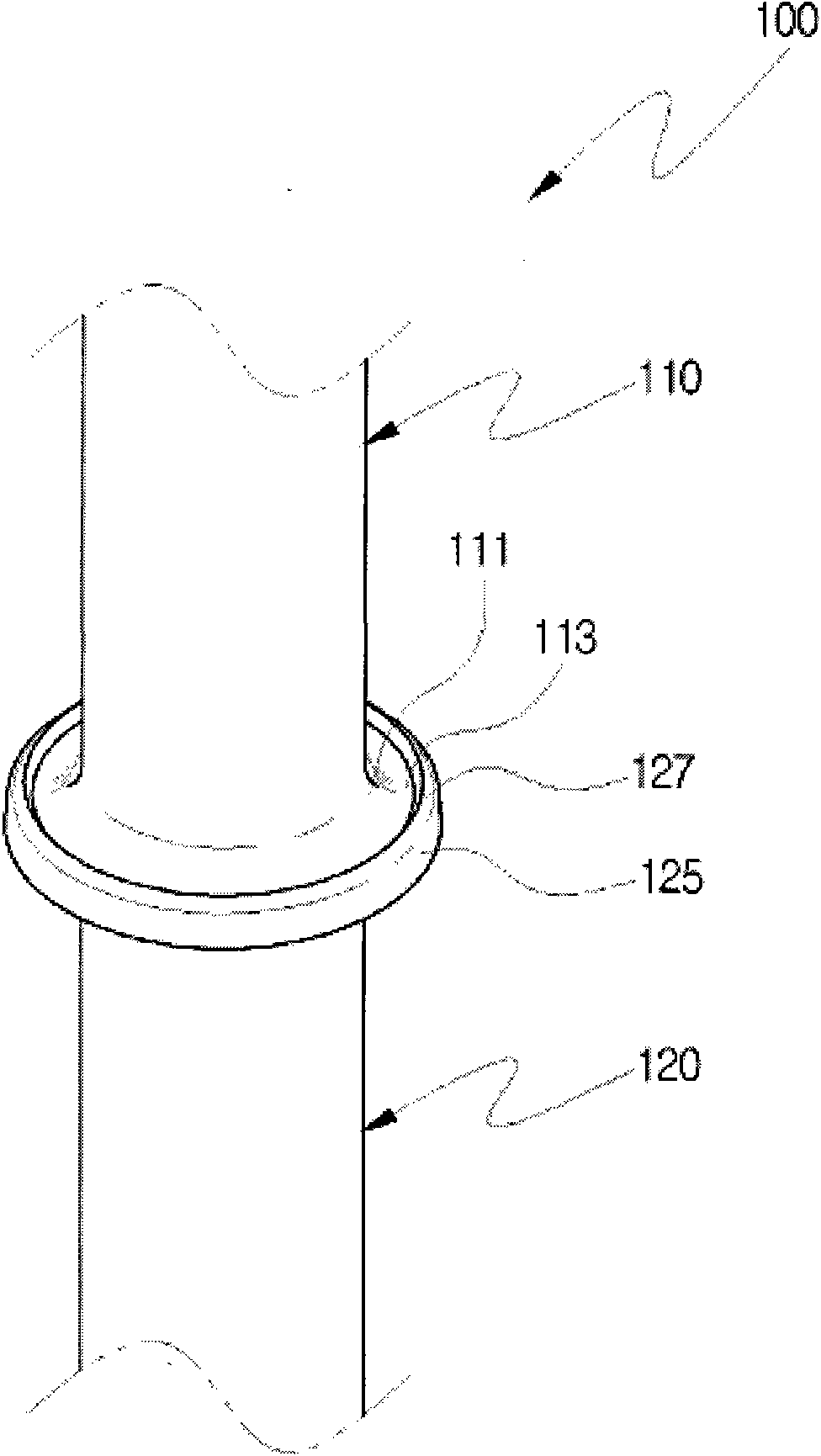

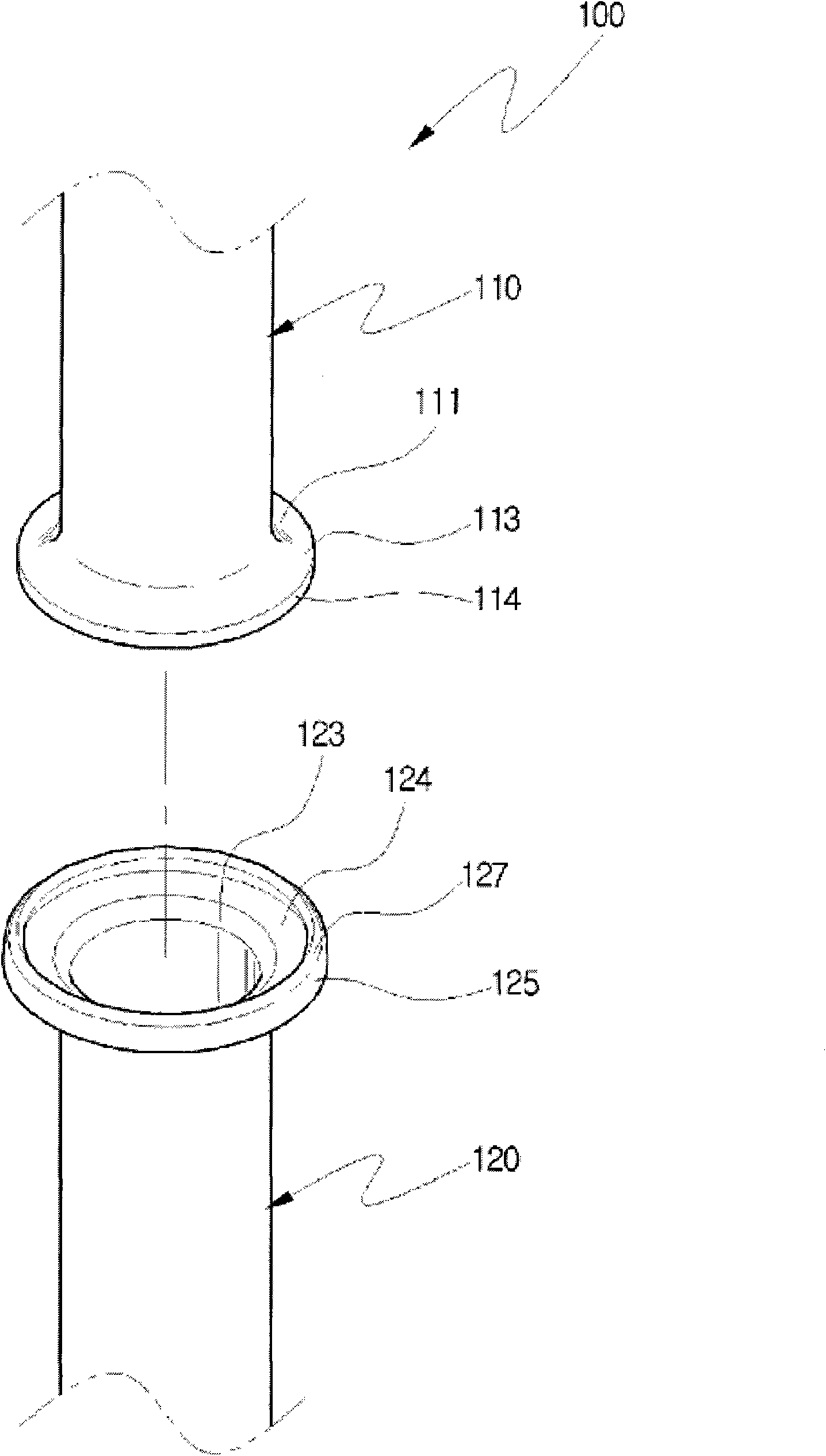

[0057] figure 2 A perspective view of a bonded pipe body using brazing according to the present invention is shown. image 3 An exploded perspective view of a bonded pipe body using brazing according to the present invention is shown. Figure 4 A cross-sectional view of a bonded pipe body using brazing according to the present invention is shown. Figure 5 A structural diagram of a bonded pipe body using brazing according to the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com